A kind of glue solution for lead-free high reliability fr-4 copper clad laminate production

A FR-4, reliable technology, used in the field of copper clad laminates, can solve the problems that ordinary circuit boards cannot fully meet, the adhesion between pads and substrates is poor, and the soldering temperature of lead-free solder is high, so as to achieve good adhesion, Low melting point temperature and the effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of lead-free high-reliability FR-4 copper clad laminate, the steps comprising:

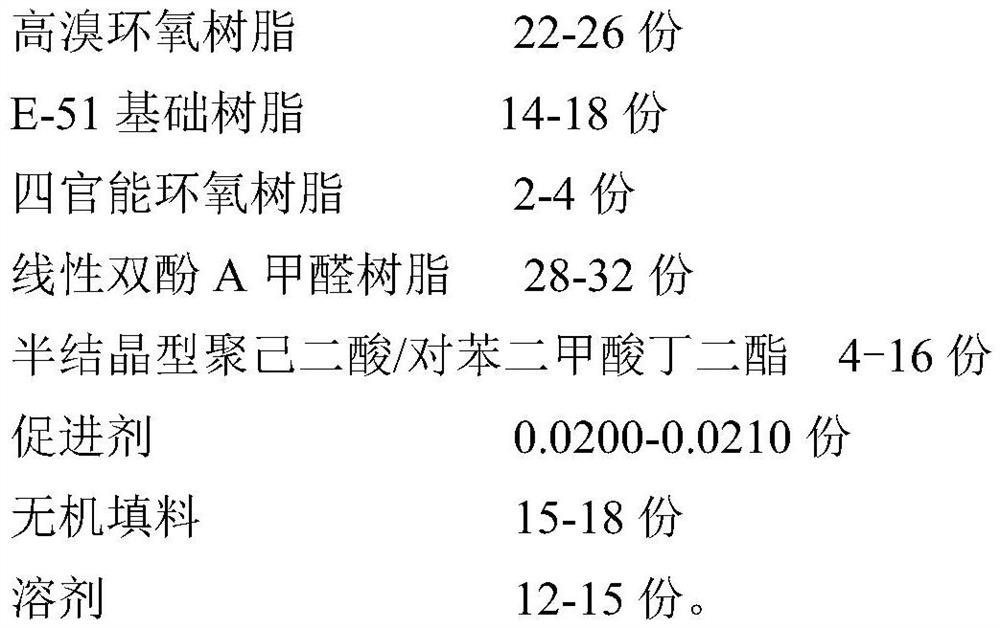

[0021] Prepare FR-4 glue according to the following glue preparation ratio:

[0022]

[0023] Put the above materials into the shear kettle according to the ratio, and add the solvent acetone, and stir at a high speed to obtain the glue solution evenly.

[0024] Immerse the above glue with electronic grade E-type glass cloth, bake it to make a prepreg, then stack the prepreg according to the requirements, and cover both sides with electrolytic copper foil at a temperature of 228°C and a surface pressure of 30kgf / cm 2 After curing for 2-3 hours under the same conditions, a high-reliability lead-free FR-4 copper-clad laminate was obtained. The main properties of the board are shown in Table 1.

Embodiment 2

[0026] A preparation method of lead-free high-reliability FR-4 copper clad laminate, the steps comprising:

[0027] Prepare FR-4 glue according to the following glue preparation ratio:

[0028]

[0029] The above materials are put into the shearing kettle according to the proportion, and the solvent butanone and propylene glycol monomethyl ether are added, and the glue is evenly obtained by stirring at a high speed.

[0030] Immerse the above glue with electronic grade E-type glass cloth, bake it to make a prepreg, then stack the prepreg according to the requirements, and cover both sides with electrolytic copper foil at a temperature of 224°C and a surface pressure of 30kgf / cm 2 After curing for 2-3 hours under the same conditions, a high-reliability lead-free FR-4 copper-clad laminate was obtained. The main properties of the board are shown in Table 1.

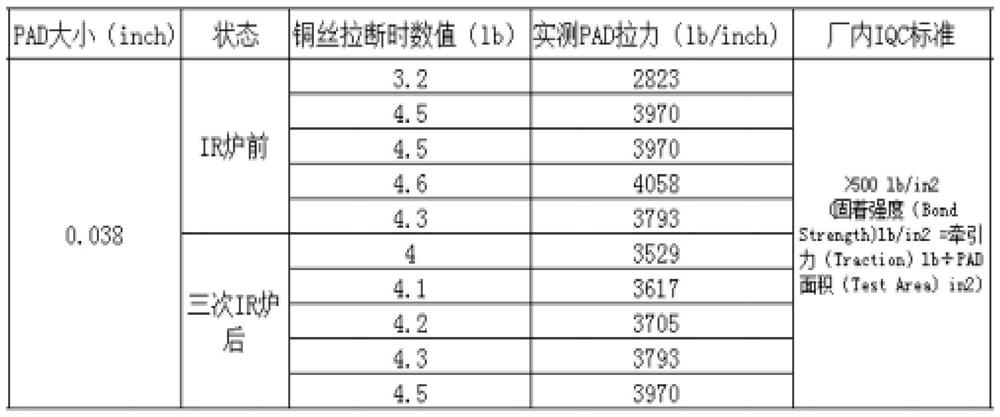

[0031] Table 1 main properties of the board

[0032]

[0033] It can be seen from Table 1 that the FR-4 board prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com