Turning rope connector used for steel wire rope and load

A technology of wire rope and connecting load, applied in the field of steering rope device, can solve the problem of no connecting rope device, etc., and achieve the effect of keeping the tension consistent, reducing the structure size, and smoothing the movement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

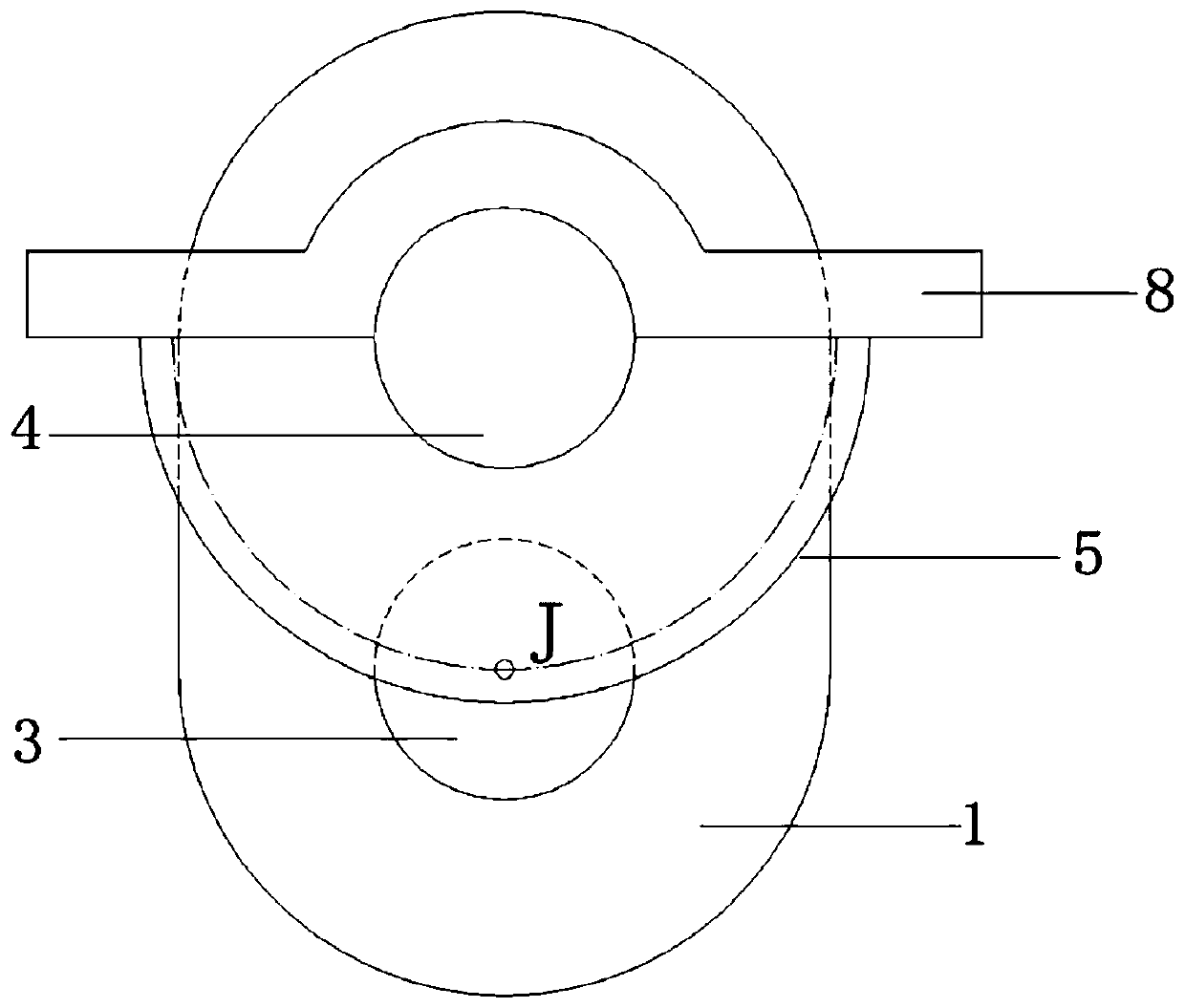

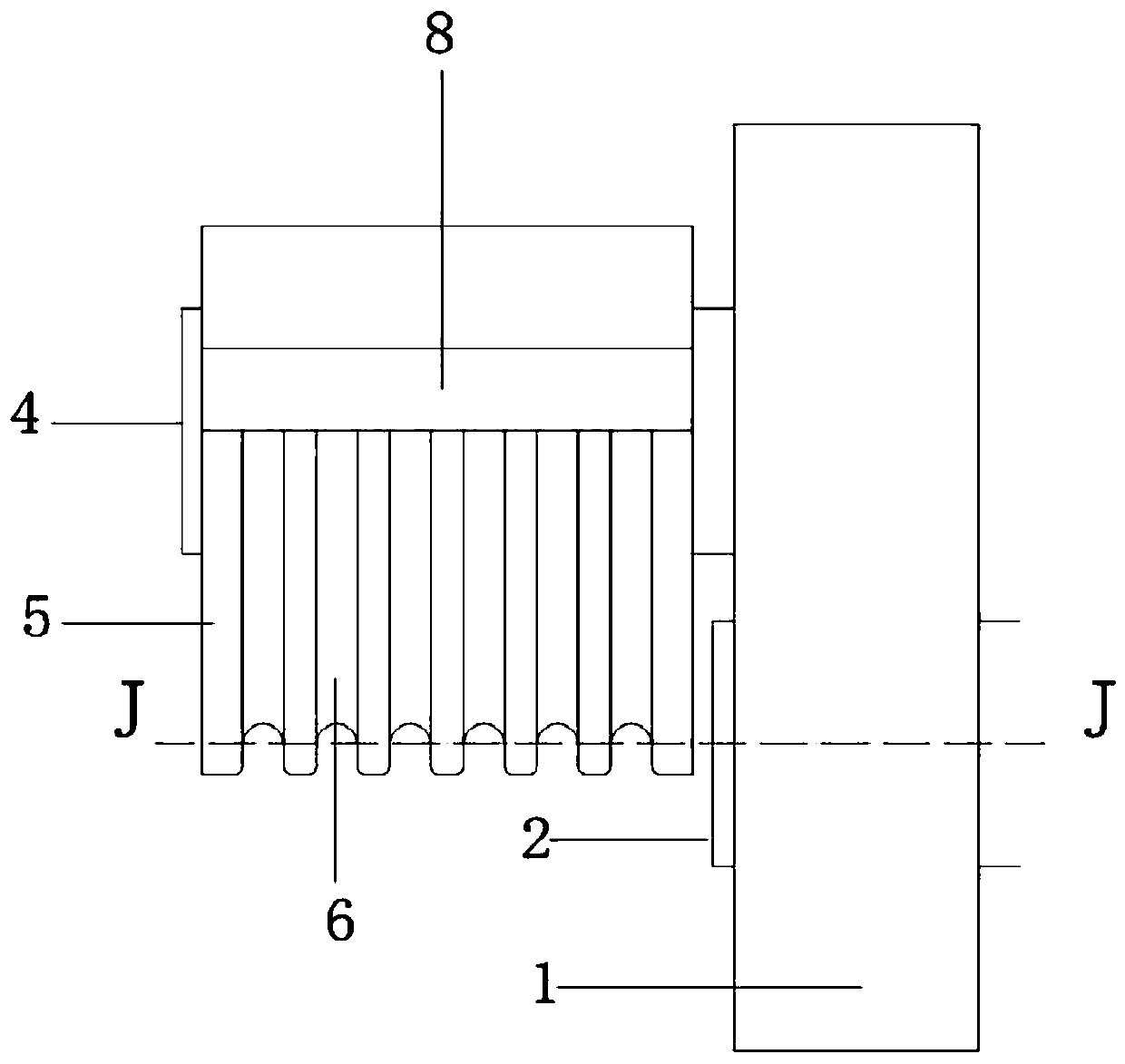

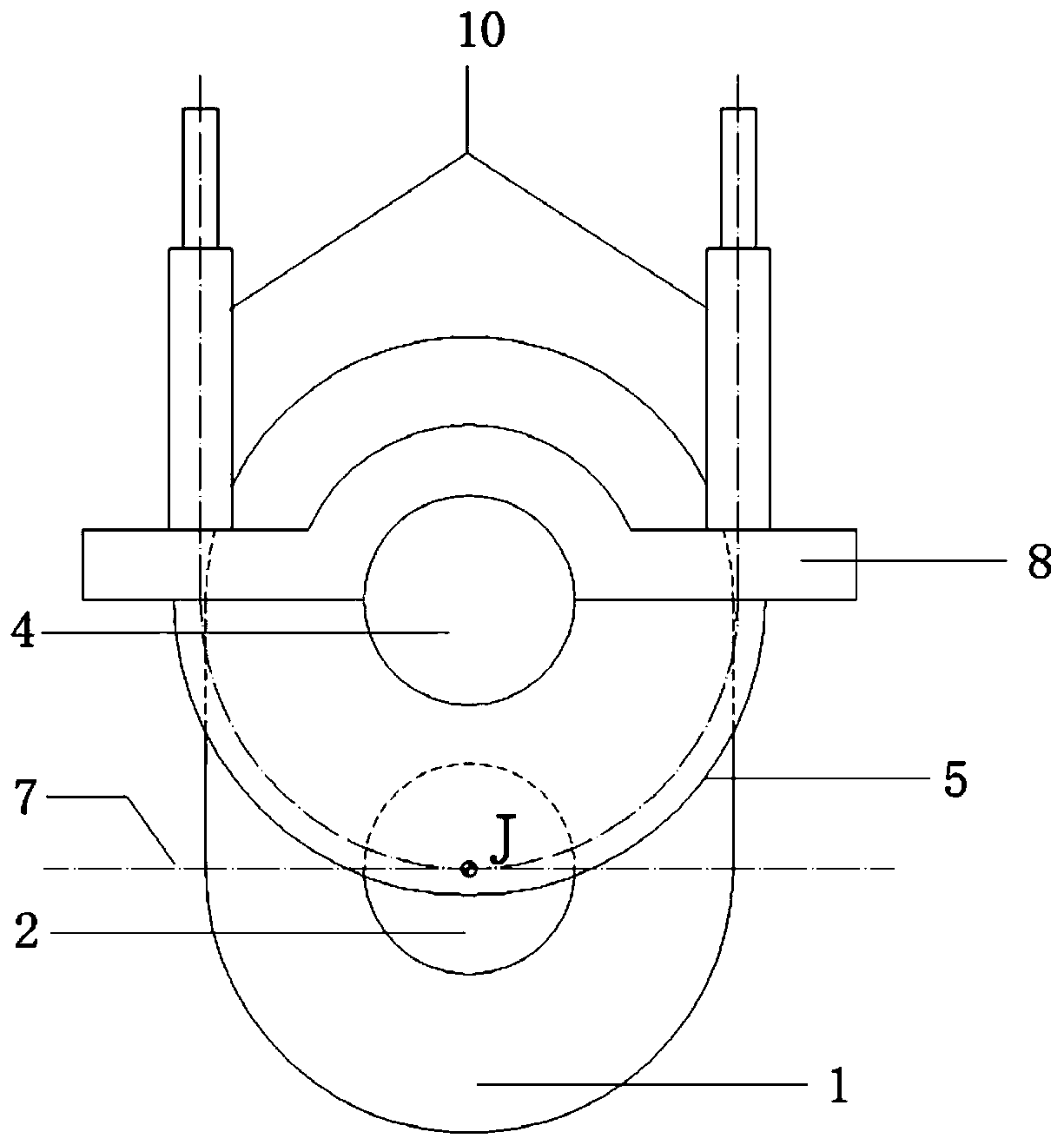

[0027] Such as Figure 1-2 As shown, a steering rope connector for a steel wire rope and a load (car) includes a crank 1, which is provided with a bearing hole 3 for connecting the load shaft 2, and a bearing is arranged in the bearing hole 3 to rotate the crank 1 ground to load shaft 2. One end of the crank 1 is provided with a connecting shaft 4, and the end of the connecting shaft 4 is provided with a semicircular arc plate 5, and a plurality of parallel rope grooves 6 are provided on the arc plate 5 along the arc surface.

[0028] For the convenience of description, in the figure, the axis of the bearing hole 3 (also the axis of the rotation axis and the load axis of the crank 1) is marked as J-J axis. The pitch circle of the rope groove 6 is orthogonal to and tangent to the J-J axis, and the point of tangency is denoted as J. Each rope groove 6 is used to wind a traction rope 7 . Both sides of the arc plate 5 are provided with a rope head plate 8, and the rope head plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com