Automobile lifting appliance with linkage and locking mechanisms

A locking mechanism and automobile technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of large free rolling range, waste of time, left and right sliding, etc., to achieve scientific and reasonable structural design, accurate hoisting positioning, and avoid sliding The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

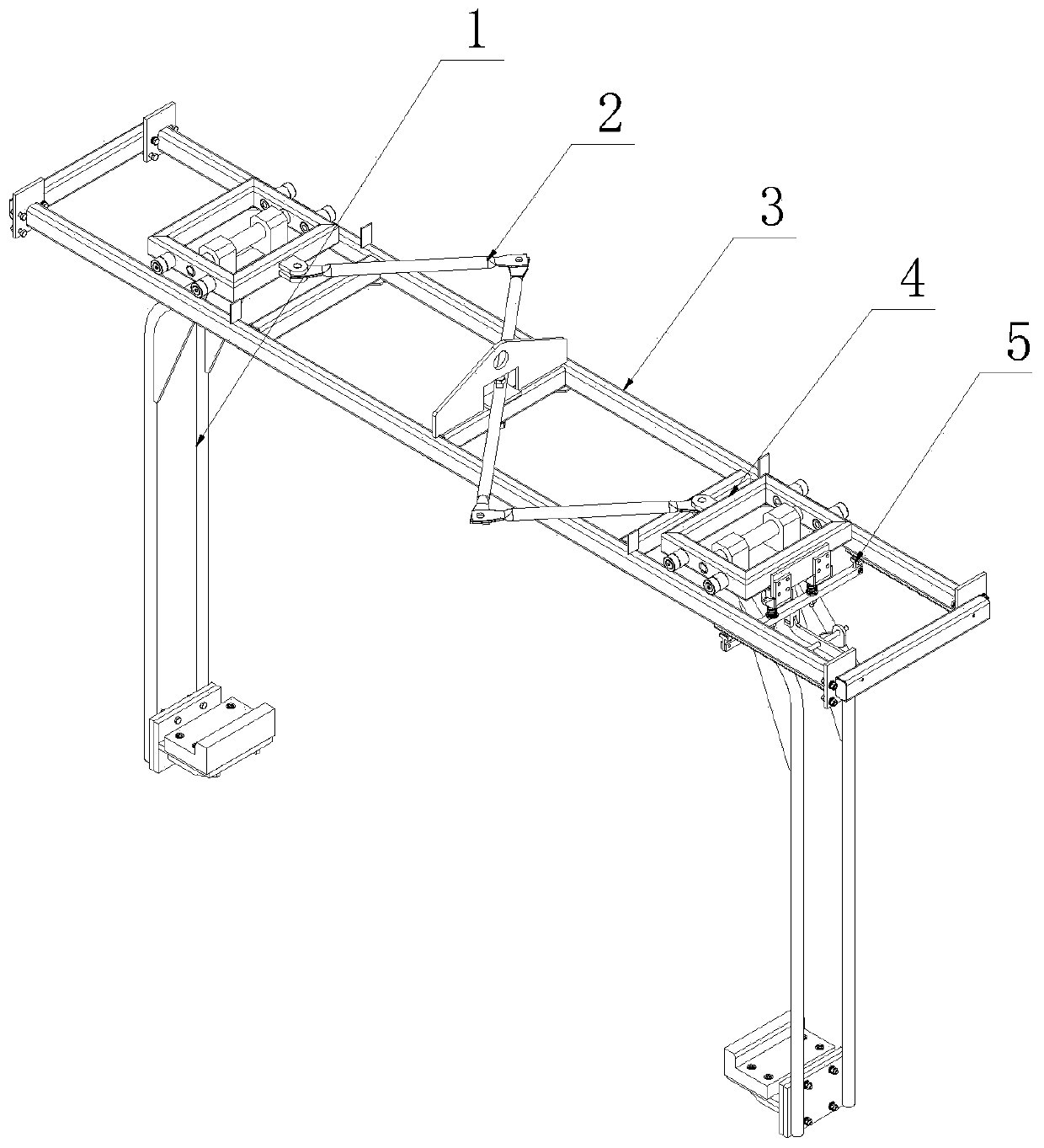

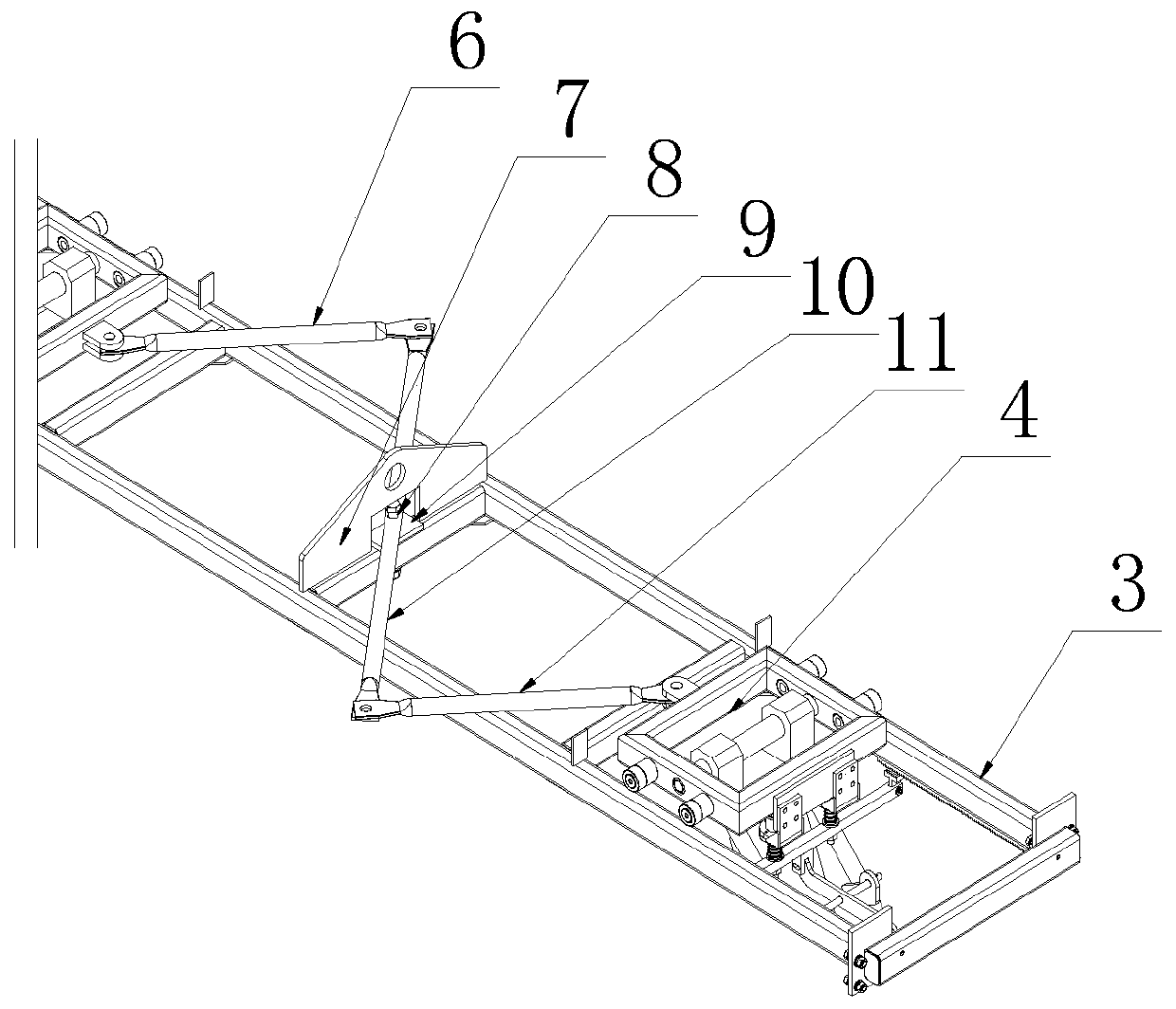

[0023] An automobile sling with a linkage and locking mechanism, comprising a hoisting frame 3, an arm 1, a walking frame 4, and its innovation lies in: it also includes a planar linkage mechanism 2, a locking mechanism 5, and the walking frame is relatively rolling. At both ends of the hoisting frame, the arms are arranged on the walking frame oppositely, the plane linkage mechanism is arranged between the walking frames, one of the locking mechanisms is fixed on the bottom of the hoisting frame, and the lower part of the other is fixed on the arms. The upper part is fixed to the walking frame.

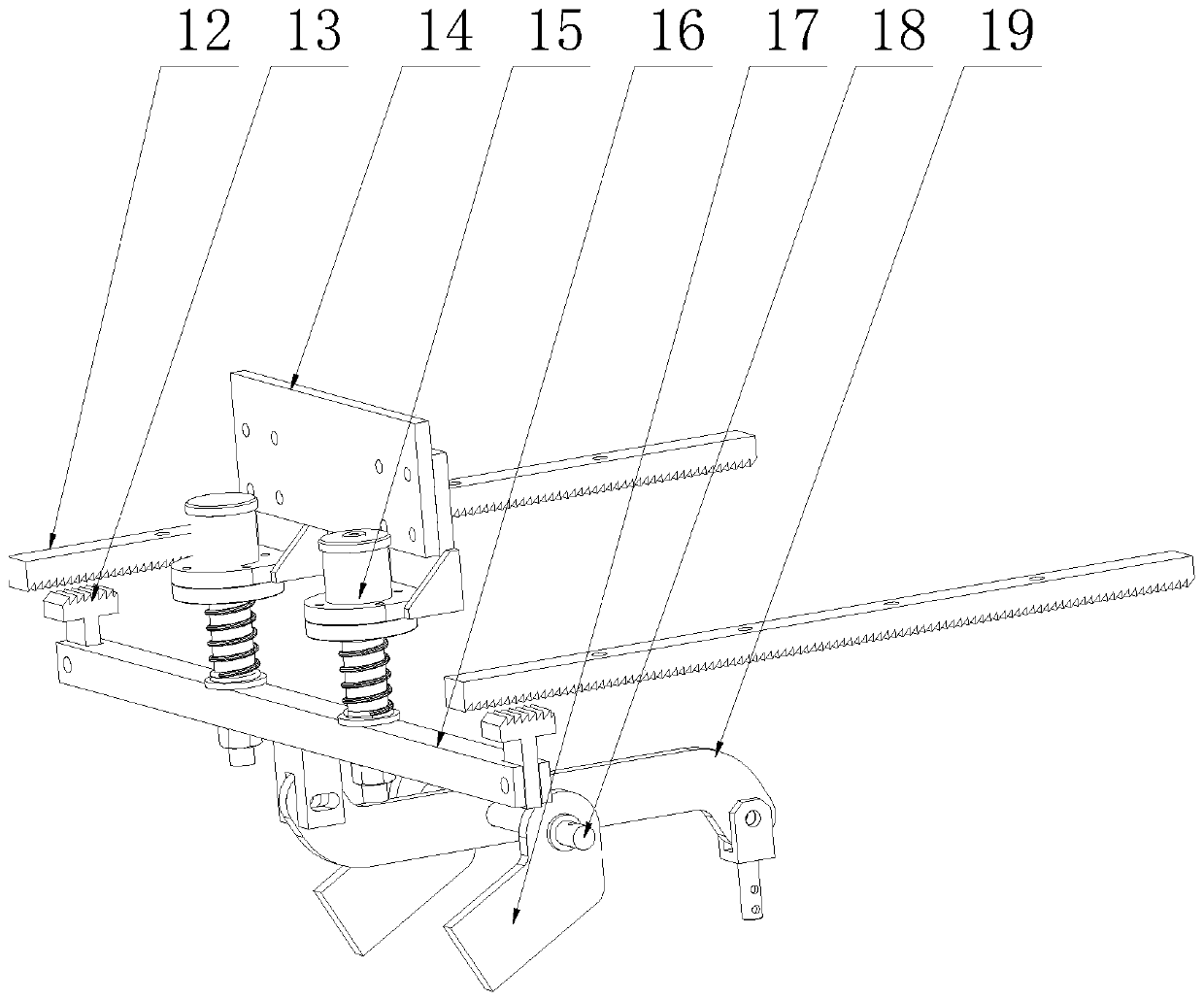

[0024] The plane linkage mechanism is composed of the limit plate 7, the hinge shaft 8, the end linkage rods 6, 11, and the intermediate linkage rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com