Aseptic workshop air circulation and waste heat recovery constant humidity unit and humidity control method thereof

A technology of waste heat recovery and air circulation, which is applied in the field of constant humidity machines, can solve problems such as waste, the filter screen of constant temperature and humidity machines, and dust entering the casing, so as to save time and effort for adjustment, improve the condensation effect, and improve the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

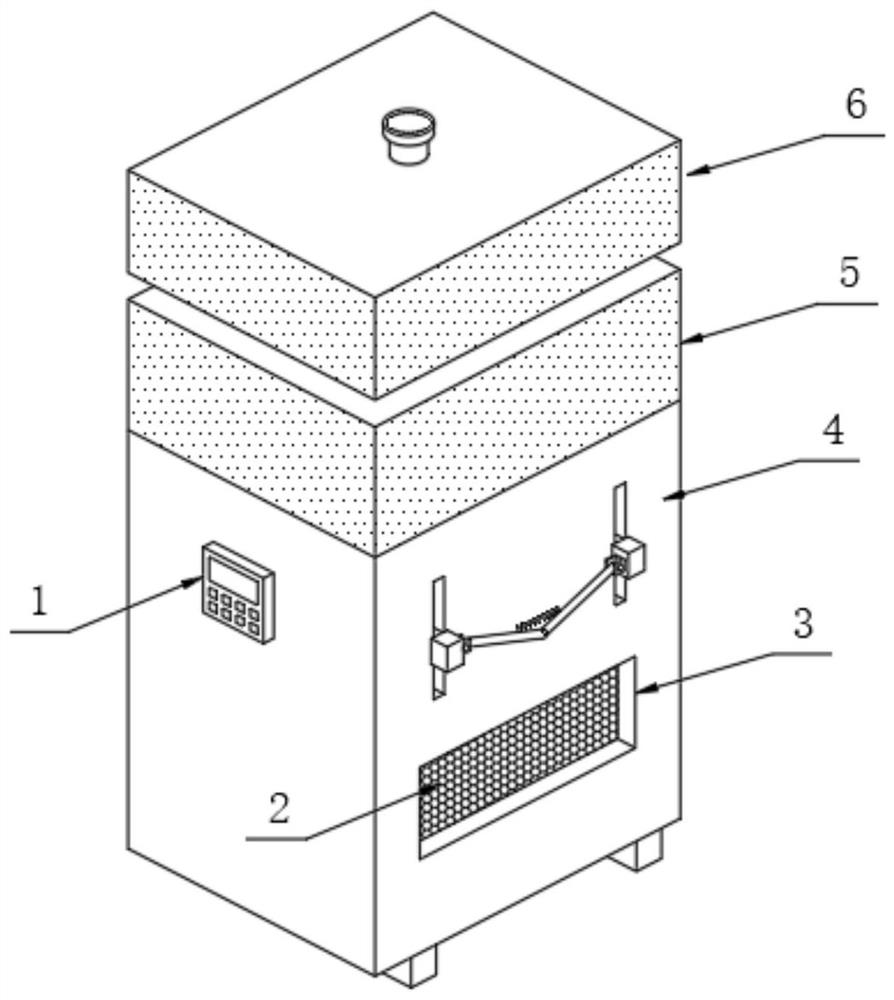

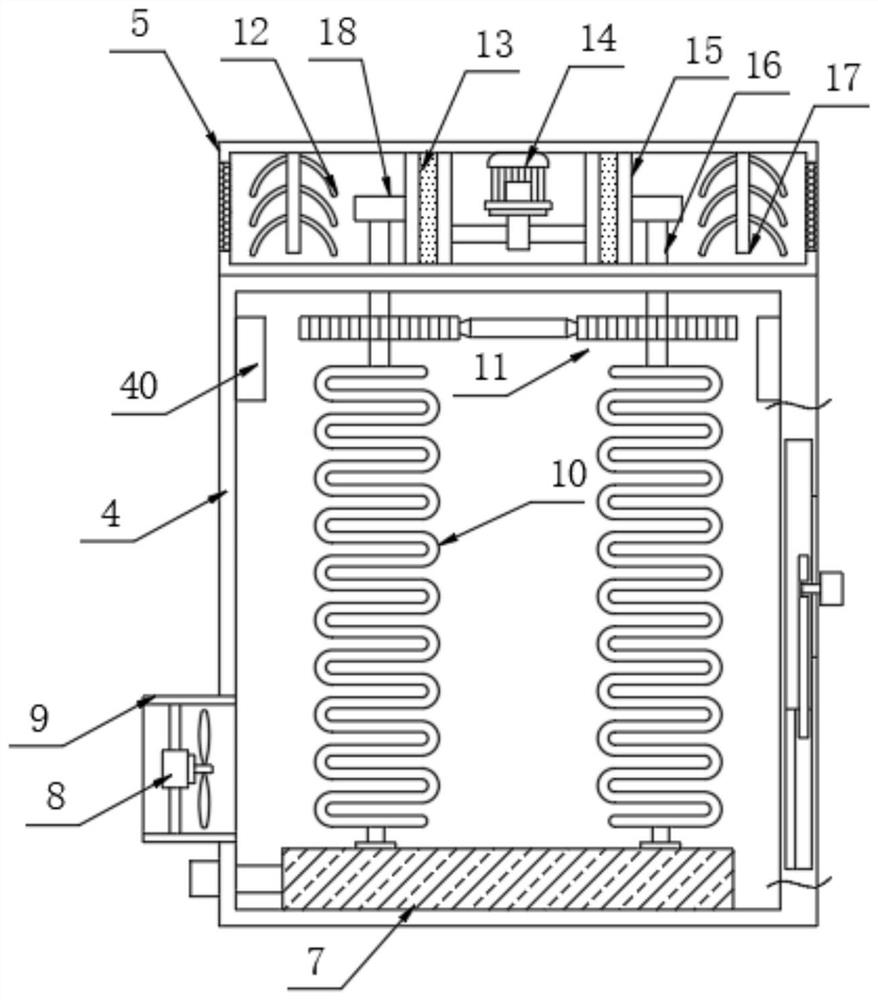

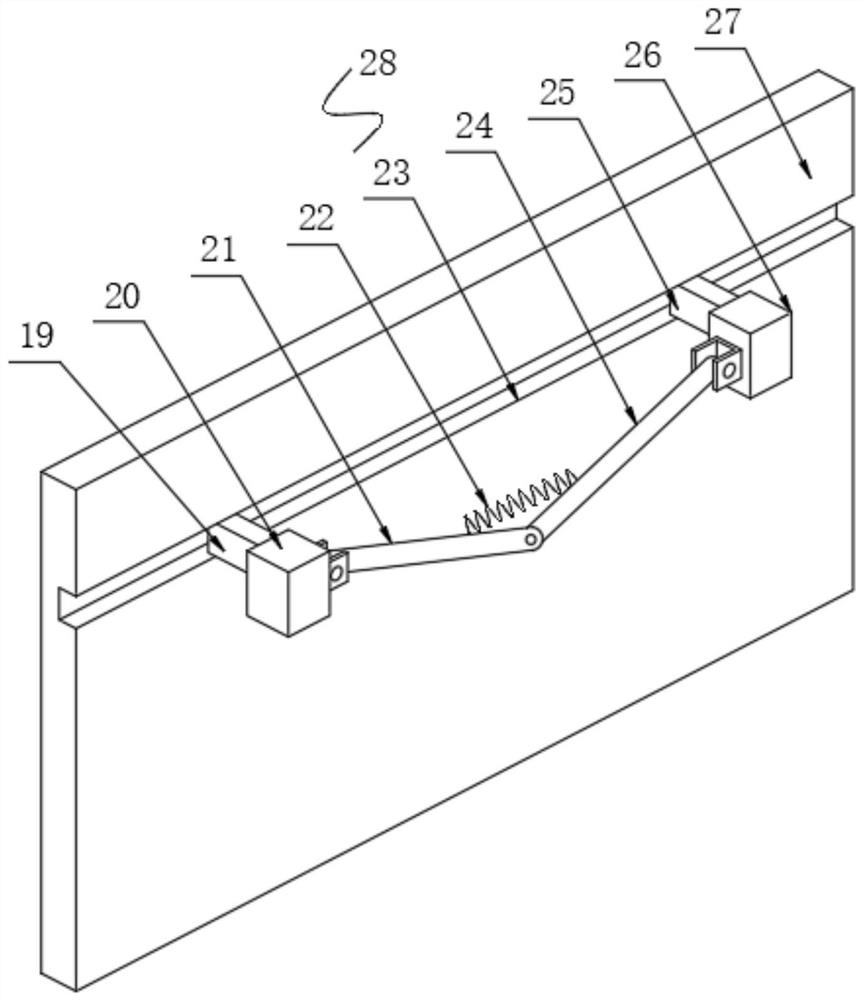

[0030] see Figures 1 to 6 , in an embodiment of the present invention, an air circulation waste heat recovery constant humidity unit for an aseptic workshop, comprising a casing 4, a controller 1 fixed on the front surface of the casing 4, and an installation groove 3 set on one side of the casing 4 And the installation cover 9 fixedly connected to the other side of the casing 4, the inside of the installation cover 9 is fixedly connected with the exhaust fan 8, the inside of the installation groove 3 is fixedly connected with the filter screen 2, and the top of the casing 4 is fixedly connected with the box body 5 , and the inside of the casing 4 is fixedly connected with a water storage tank 7, and both sides of the box body 5 are provided with ventilation holes. An air pump 14 is connected, and the inside of the box body 5 is located on both sides of the air pump 14, and cooling boxes 15 are fixedly connected. The air outlet end of the air pump 14 is sealed and fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com