Monocrystalline silicon growth furnace one-furnace multitime doping device

A growth furnace and monocrystalline silicon technology, which is applied in the field of multiple doping devices in one single crystal silicon growth furnace, can solve the problems of low quality of semiconductor crystal rods and uneven distribution of doping substances, so as to save manpower and increase profits , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

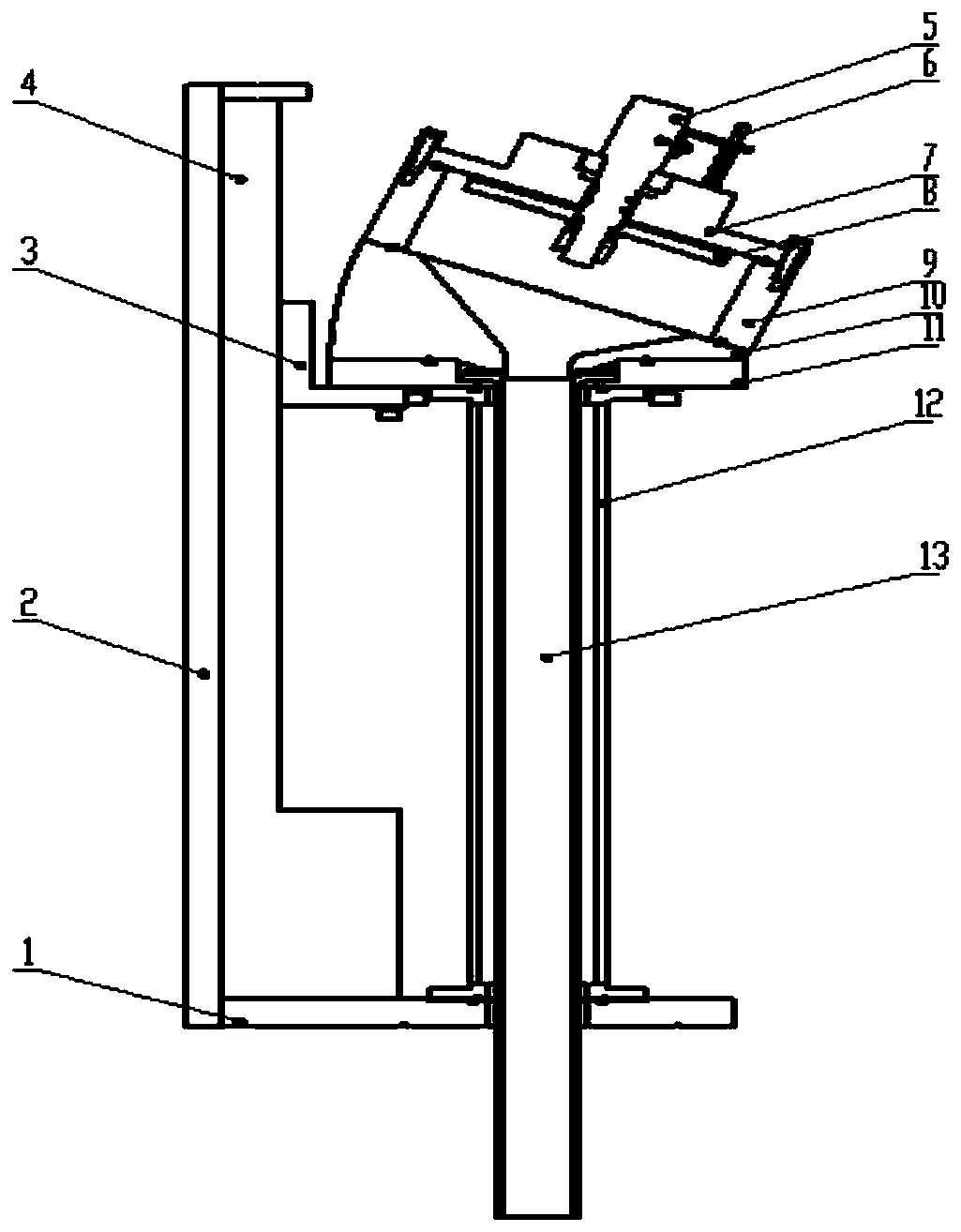

[0024] Such as figure 1 As shown, a single crystal silicon growth furnace-furnace multiple doping device includes a doping cylinder 15; a lifting mechanism and a doping mechanism are also included.

[0025] The lifting mechanism includes a lower bottom plate 1 and a back plate 2 . A linear motion unit 4 is vertically provided on the back plate 2 , and a lifting frame 3 is provided on the slider of the linear motion unit 4 . A round hole is arranged on the lower bottom plate 1 .

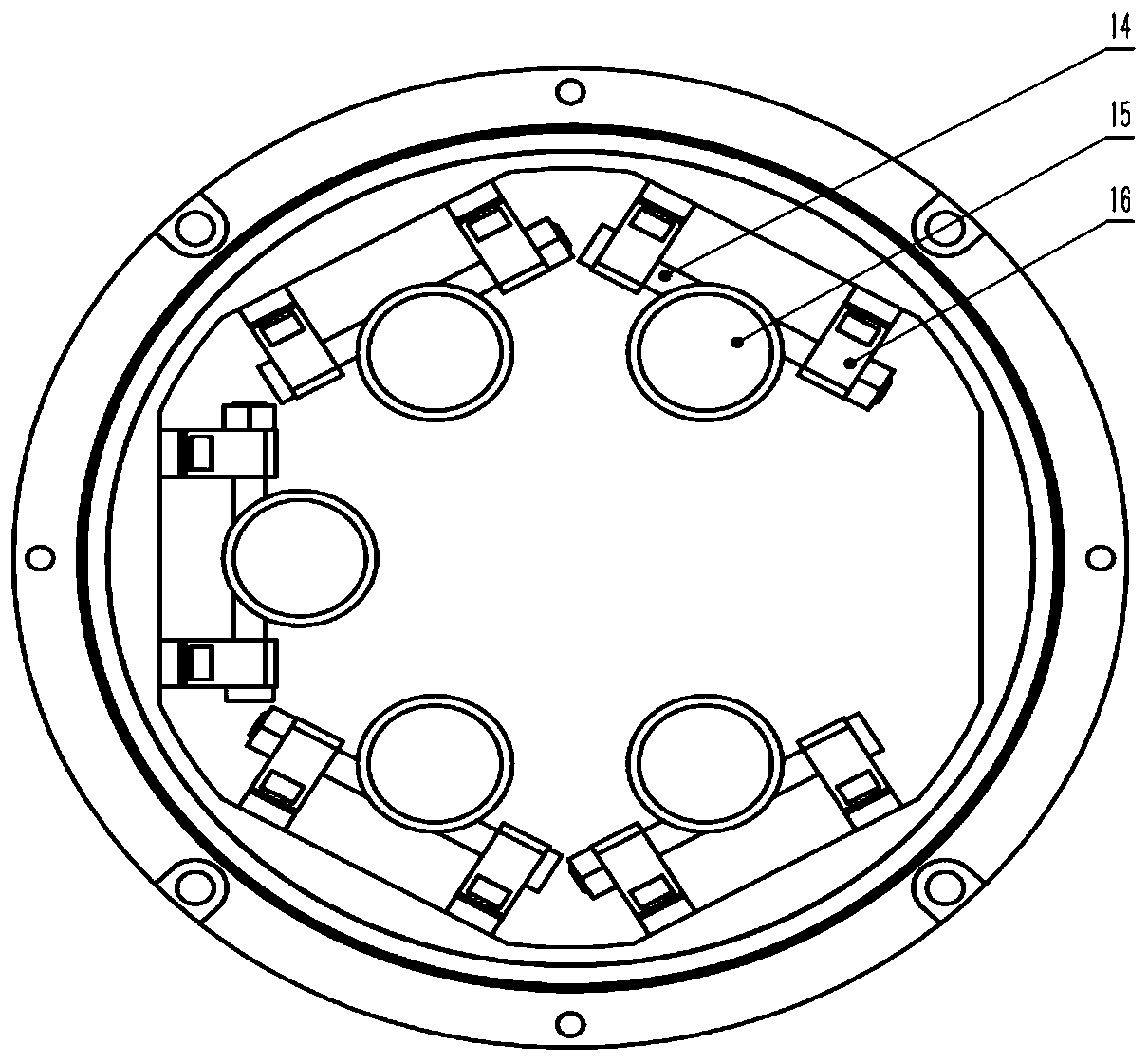

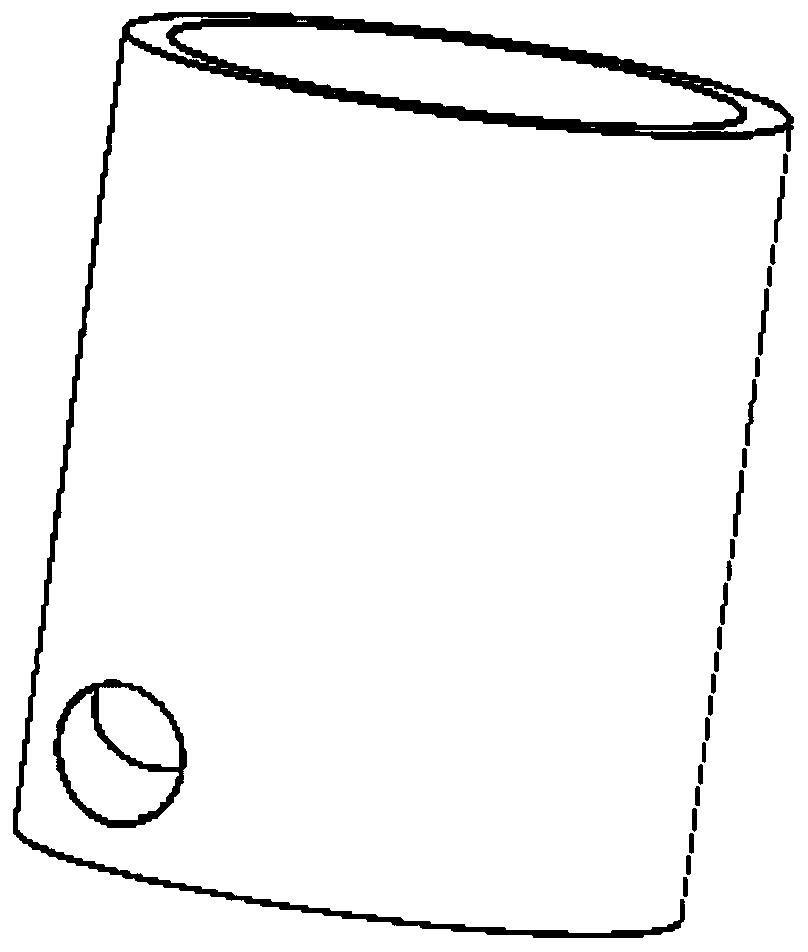

[0026] Such as figure 2 As shown, the doping mechanism includes an outer cylinder 9 . The inner ring of the outer cylinder is N-sided. Each of the N-1 sides is provided with a shaft seat 16 , and the spare side is the initial position, and each shaft seat 16 is provided with a mandrel 14 . Such as image 3 As shown, an eccentric hole is provided on the bottom wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com