Fine crushing device for construction waste

A crushing device and construction waste technology, which is applied in the direction of construction waste recycling, recycling technology, grain processing, etc., can solve the problems of non-recycling, large aggregate particle size, and poor crushing effect, so as to improve the screening efficiency , to avoid the effect of sieve clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

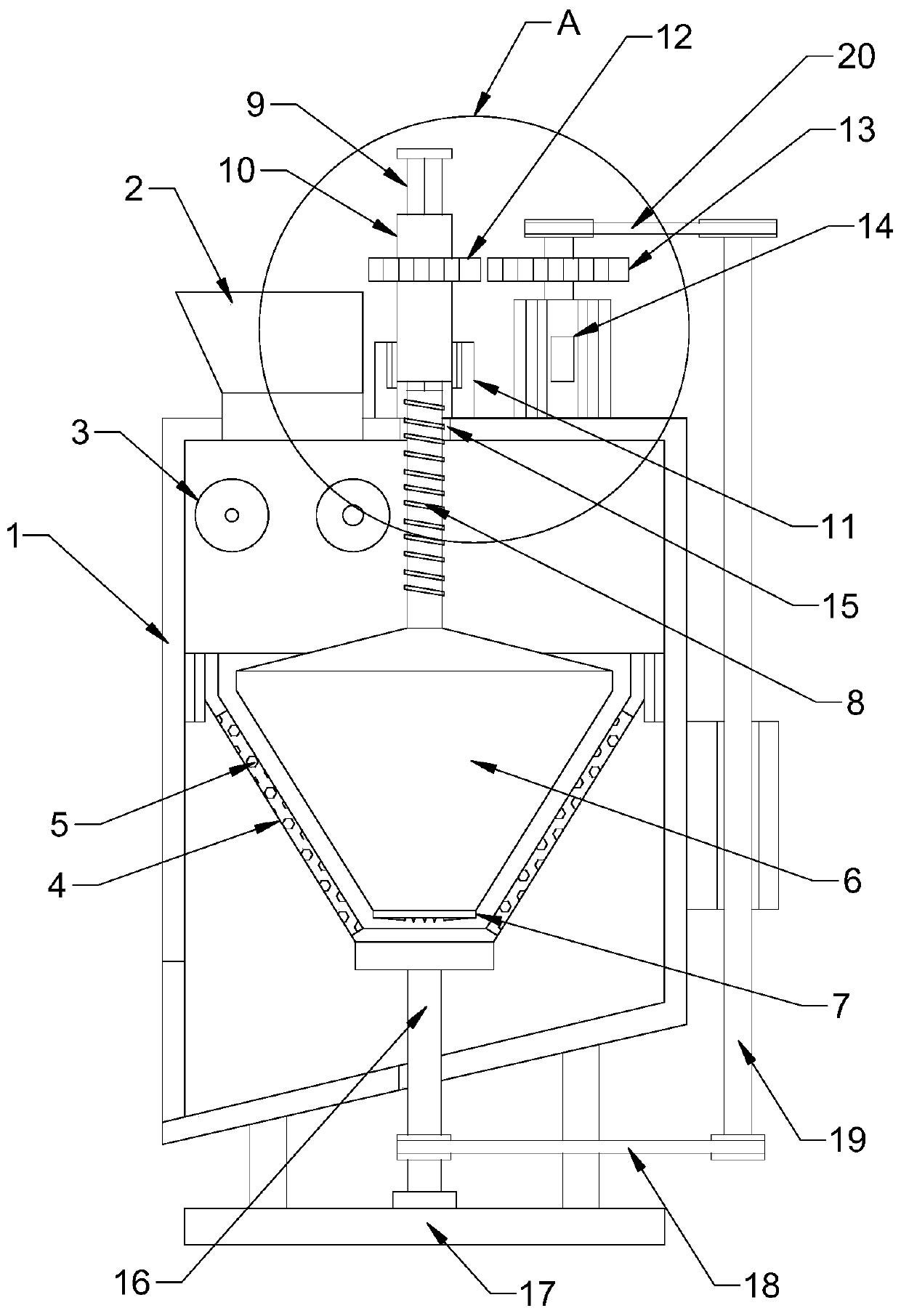

[0021] see Figure 1-4 , in an embodiment of the present invention, a construction waste fine crushing device includes a box body 1 and a crushing roller group 3; the upper end of the box body 1 is connected with a feeding hopper 2, and the construction waste is thrown into the box body from the feeding hopper 2 1; under the feeding hopper 2, there is a crushing and crushing roller group 3, which includes a set of crushing rollers arranged opposite to each other, and is used for preliminary crushing of construction waste for subsequent processing.

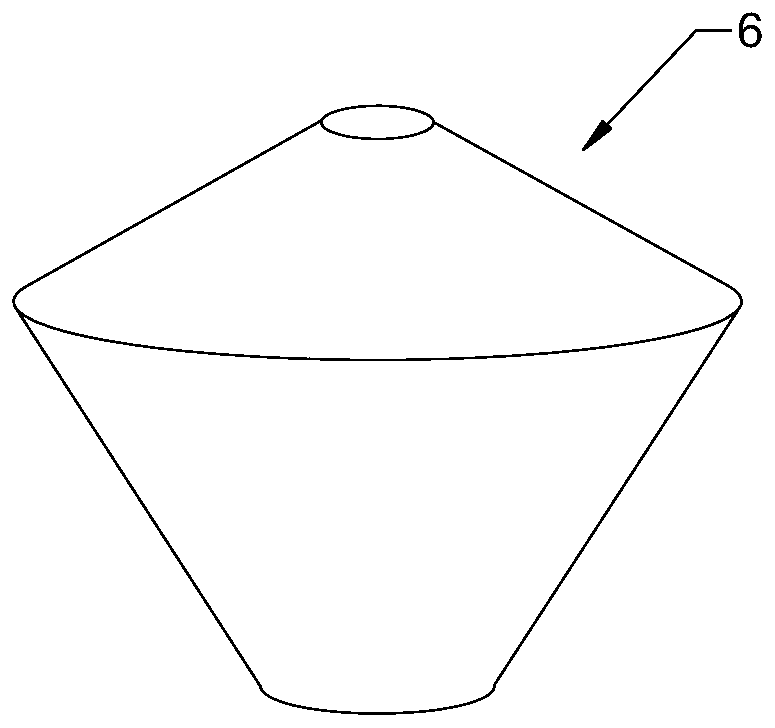

[0022] The box body 1 is provided with a grinding cylinder 4, the grinding cylinder 4 is a conical cylinder with an upper end open and set upside down, and evenly distributed sieve holes 5 are provided on the conical surface of the grinding cylinder 4, so as to facilitate the timely discharge of crushing materials that meet the crushing requirements. Garbage particles; the grinding cylinder 4 is nested with a grinding head 6, and t...

Embodiment 2

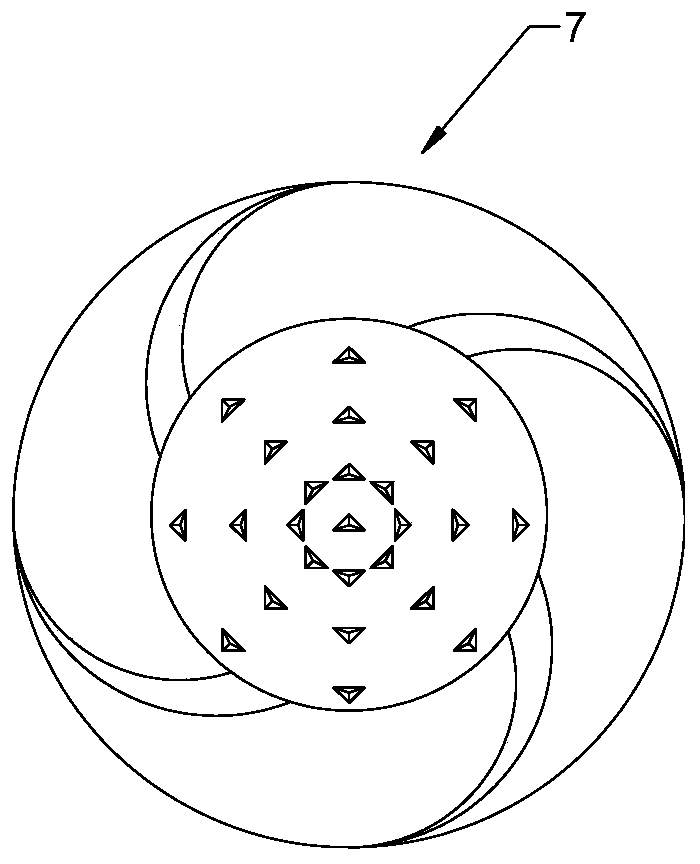

[0027] The difference between this embodiment and Embodiment 1 is that: the lower end of the grinding head 6 is fixedly connected with a rolling plate 7, and the lower end surface of the rolling plate 7 is provided with rolling teeth and arc-shaped convex corrugations, and the rolling plate 7 follows the grinding head. 6. Rotate downwards to crush and crush the construction waste accumulated at the bottom of the grinding cylinder 4. At the same time, the arc-shaped convex corrugations will move and screen the rolled particles to the outside to avoid accumulation of construction waste.

[0028] The lower end of the grinding cylinder 4 is fixedly connected with a support shaft 16, the support shaft 16 runs through the box body 1 and extends to the bottom of the box body 1, the support shaft 16 is connected to the base 17 through the bearing seat, and the support shaft 16 passes through the first transmission belt 18 is connected with transmission shaft 19, and transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com