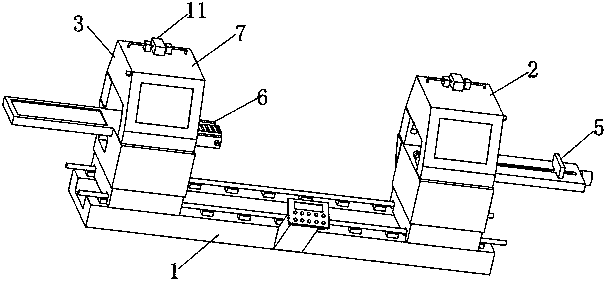

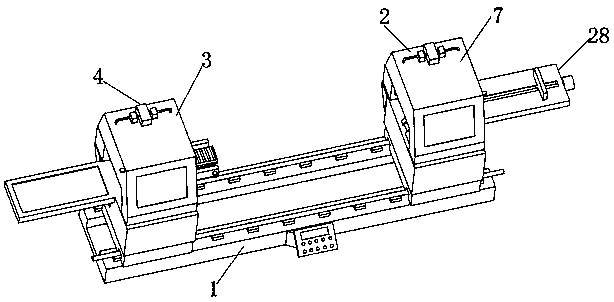

Protection device for saw-cutting machine with three-axis polar coordinates

A protective device and polar coordinate technology, which is applied to the attachment of sawing machines, metal sawing equipment, maintenance and safety accessories, etc., can solve the problems of working components and sawing mechanism wear, slow manual loading and unloading speed, and potential safety hazards. Achieve the effect of improving precision and cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

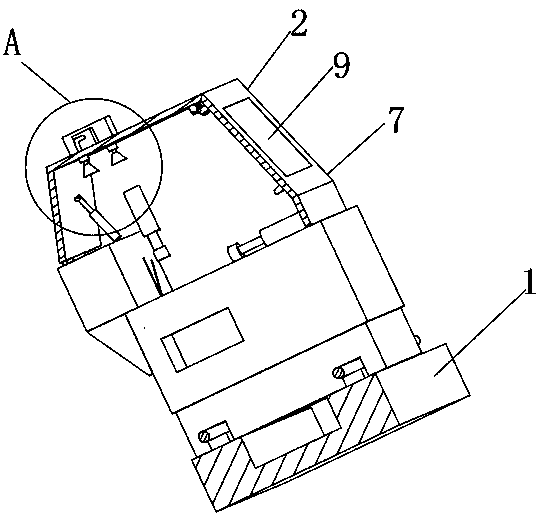

[0033] Specific embodiments: when the first cutting table 2 and the second cutting table 3 are working, the telescopic cylinder 8 operates, so that the two protective covers 7 are attached to the first cutting table 2 and the second cutting table 3 respectively, and Rotate the motor 12 to run, so that the driving gear 13 drives the driven gear 14 to rotate, so that the driven gear 14 drives the screw mandrel 15 to rotate, and because the drive sleeve 17 is rotated and socketed on the outside of the screw mandrel 15, the drive sleeve 17 is received by the drive rod 18 at the same time. The limit function of the sliding sleeve 23 at the other end makes the driving rod 18 move relative to the transparent window 9, thereby driving the brush 20 to clean the transparent window 9. At the same time, the two exhaust fans 25 run to make the aluminum The waste chips generated during profile cutting enter into the dust collection box 24 through the dust suction head 27, so as to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com