Laser cutting head protective lens mounting module capable of detecting existence or inexistence of protective lens

A technology for laser cutting head and protective lens, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that there is no device and method for detecting the presence or absence of a lens, and it is easy to miss or misplace the protective lens and pollute Problems such as the internal structure and lens of the cutting head, to improve the efficiency and convenience of replacement, reduce the pollution of the internal structure and lens, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

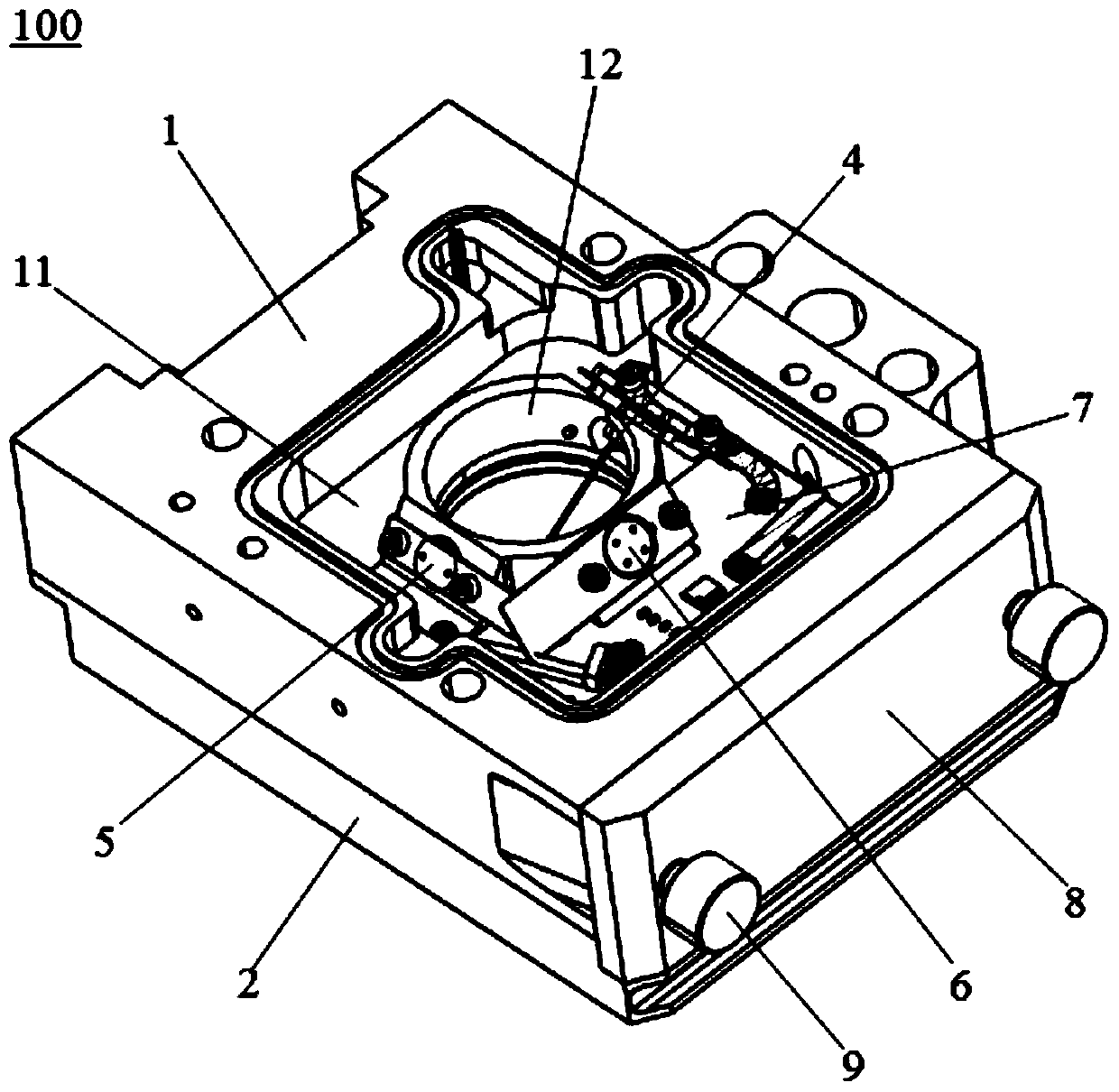

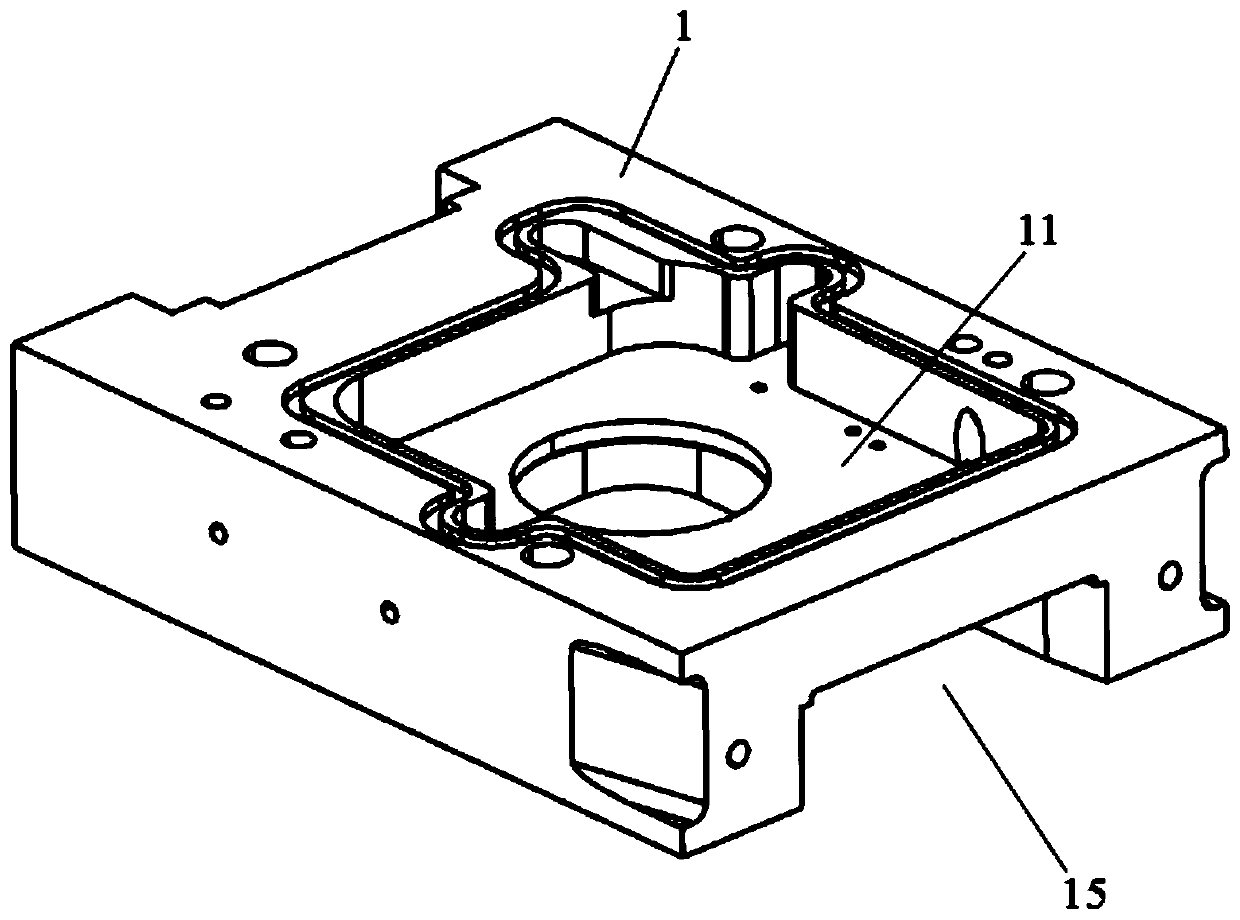

[0023] Please refer to Figure 1-Figure 5 , the present embodiment is a protective lens installation module 100 in a laser cutting head that can detect whether the protective lens is present. Mounting seat 2, a protective lens mounting seat 3 embedded in the lower surface of the sensor mounting seat 1 and can be extracted from one end of the sensor mounting seat 1, an annular cylinder 12 is fixedly arranged in the sunken groove 11, and on the annular cylinder 12 A red light emitter 4 and a red light receiver 5 are symmetrically arranged, and the red light emitter 4 emits red light to the protective lens in the protective lens mount 3 and shoots to the red light receiver 5 after being refracted.

[0024] The bottom of the annular cylinder 12 is a hollow structure and goes straight through the protective mirror 101 . The outer circumferential surface of the annular cylinder 12 is provided with several installation support surfaces 13, and the cylinder is provided with transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com