Pneumatic ejection mold

A pneumatic and ejection technology, applied to presses, manufacturing tools, etc., can solve problems such as difficulty in finding equipment failures, high costs, and inaccurate judgments, and achieve the effects of simple structure, good use effect, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described below with reference to the accompanying drawings; however, it should be understood that these descriptions are illustrative only and are not intended to limit the scope of the present disclosure. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concepts of the present disclosure. All terms (including technical and scientific terms) used herein have the meaning commonly understood by one of ordinary skill in the art, unless otherwise defined. It should be noted that the terms used herein should be interpreted to have a meaning consistent with the context of this specification, and not be interpreted in an idealized or overly rigid manner.

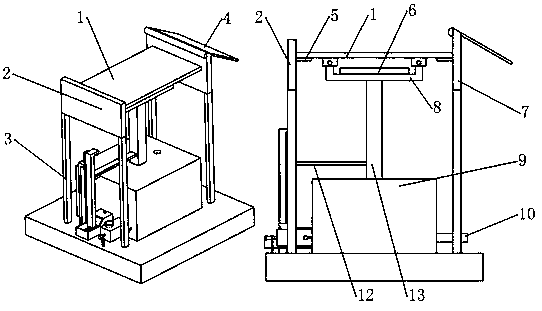

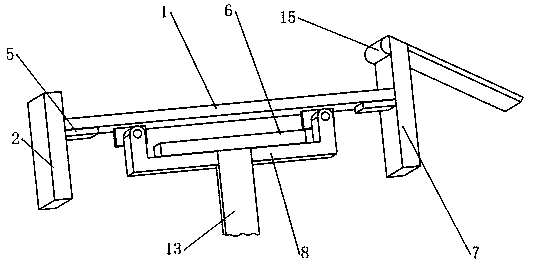

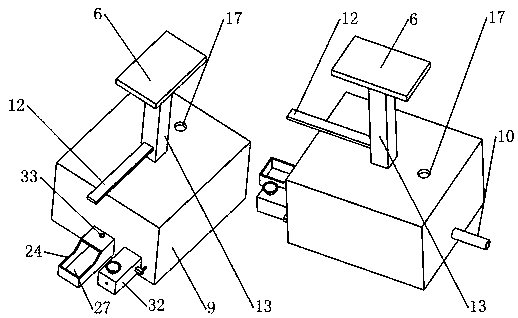

[0042] A pneumatic ejection mold, such as figure 1 , 4 , 6, and 11, it includes push plate 1, A support plate 2, slide plate 4, support plate 5, push platform 6, B support plate 7, U-shaped plate A8, cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com