Ejection mechanism for test paper box positioning

A technology of ejecting mechanism and test paper box, applied in the field of medical testing, can solve the problems of inability to realize automatic and precise positioning, large volume of the test paper box transport mechanism, troublesome operation, etc., and achieves convenient assembly and maintenance, simple structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

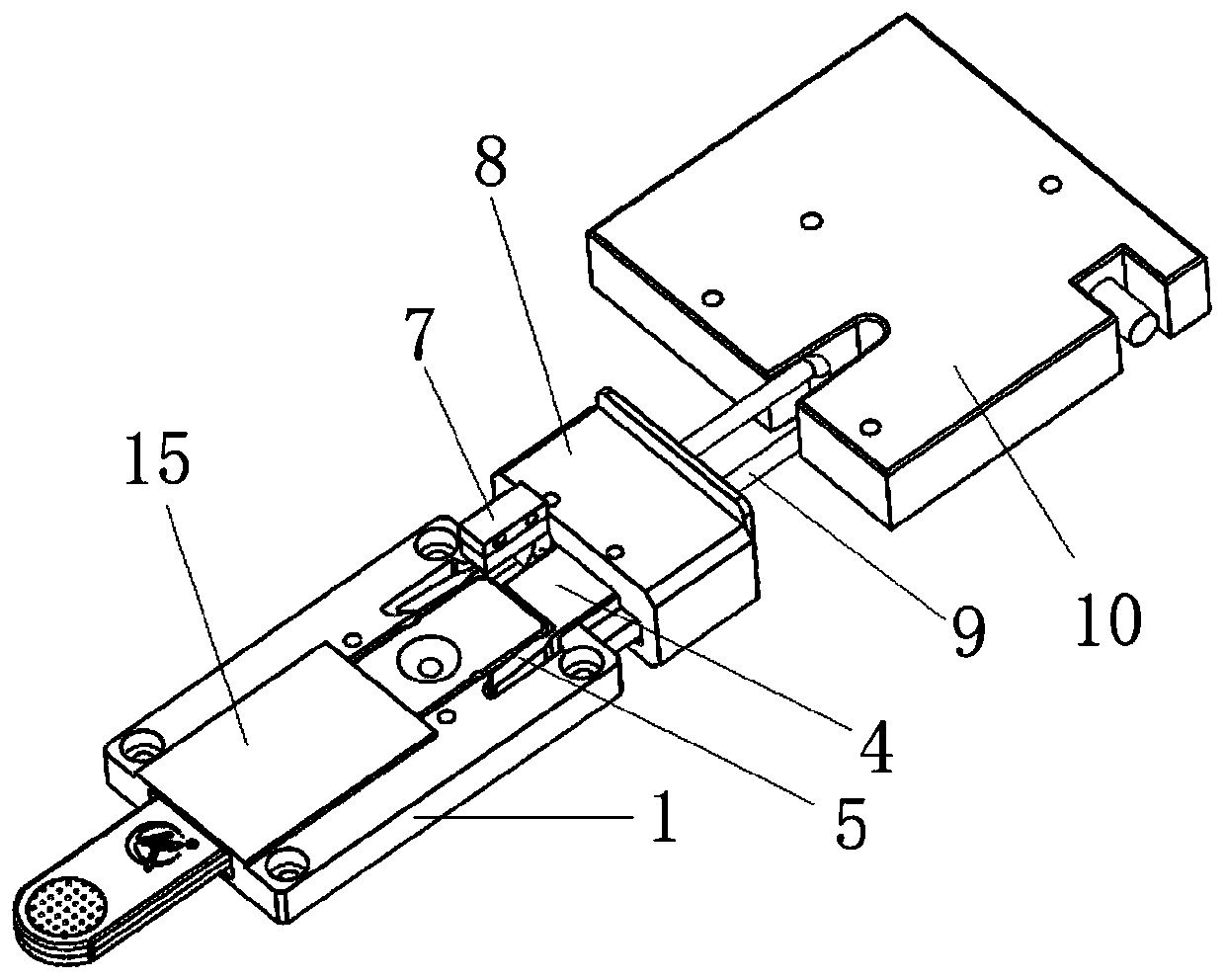

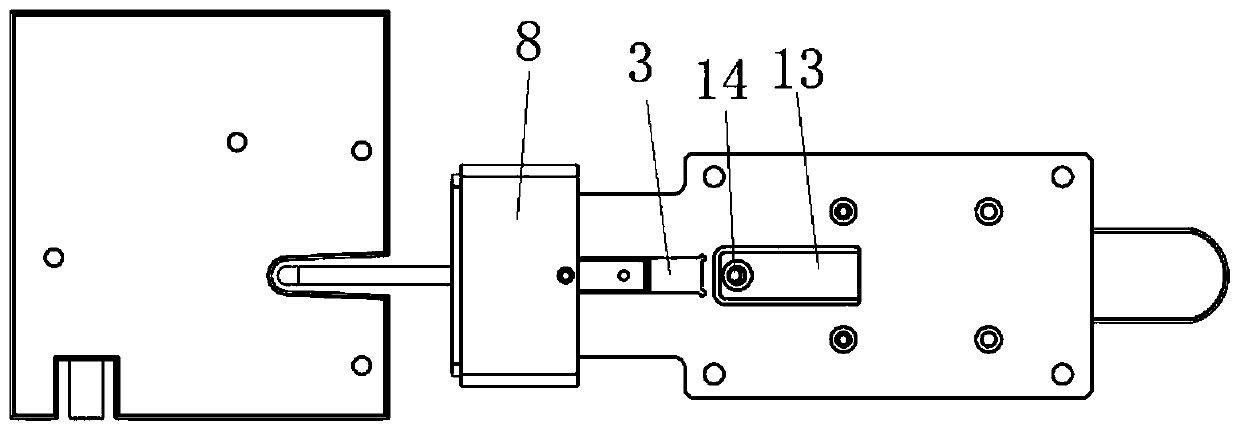

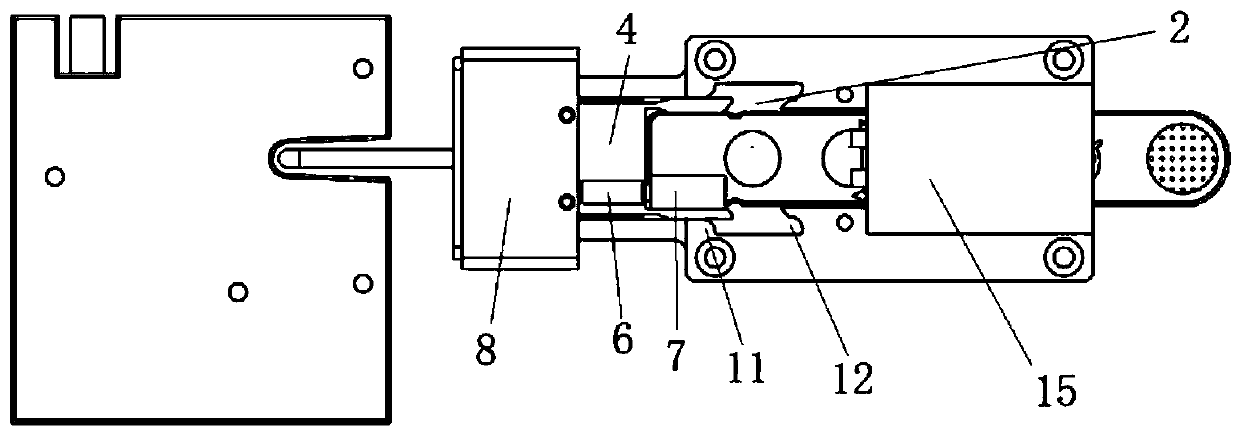

[0026] see Figure 1 to Figure 4 , the pop-up mechanism for the positioning of the test paper box includes a test paper box guide seat 1, the test paper box guide seat 1 is provided with a test paper box guide groove 2; one end of the test paper box guide groove 2 is provided with a test The entrance of the paper box, the test paper box guide groove 2 is provided with a test paper box jaw slider guide groove 3, and the test paper box jaw slider guide groove 3 is equipped with a slider that can move along the test paper box jaw The test paper box jaw slider 4 that slides in the guide groove 3, the test paper box jaw slider 4 is provided with a test paper box jaw 5 and a travel switch empty groove 6, and the open space of the test paper box jaw 5 The mouth end faces the entrance of the test paper box; the end opposite to the entrance of the test paper box on the test paper box guide seat 1 is provided with a travel switch 7; 9, the lock ring 9 is movably connected with the auto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap