Mechanism for conveying test paper strips

A test strip and test strip technology, applied in the field of medical testing, can solve the problems of affecting the test results, difficult handling of urine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

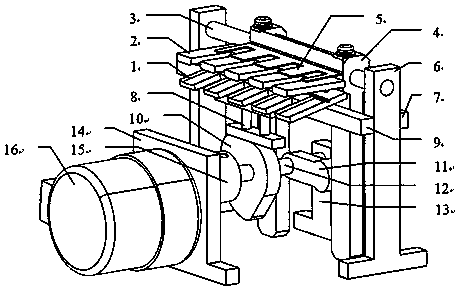

[0018] see figure 1 and figure 2 , the described mechanism for test strip transmission includes a shaft mount 6; the top of the shaft mount 6 is provided with a test paper clip shaft 3; the test paper clip shaft 3 is provided with a test paper clip slide bar 4, and the test paper clip Both sides of the slide bar 4 extend to the bottom of the rotating shaft mounting seat 6; the test paper clip slide bar 4 is provided with a test paper clip, and the test paper clip includes an upper test paper clip 2 and a lower test paper clip 1; There is a lifting rod support 9, and the lifting rod support 9 is provided with a test paper clip lifting rod 8 for promoting the lower test paper clip 1 to rise; the lower part of the test paper clip lifting rod 8 is provided with a lifting rod cam 10, and the lifting rod The top surface of the cam 10 is in contact with the bottom surface of the test paper clip lifting rod 8; the lifting rod cam 10 is installed on the motor shaft 12; one end of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap