Multilayer rolling shaft type automatic binding storage box

An automatic binding and storage box technology, applied in transportation and packaging, stack receiving device, thin material handling, etc., can solve problems such as imperfect privacy measures for customers' private information, no binding of cloud printers, and waste of human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

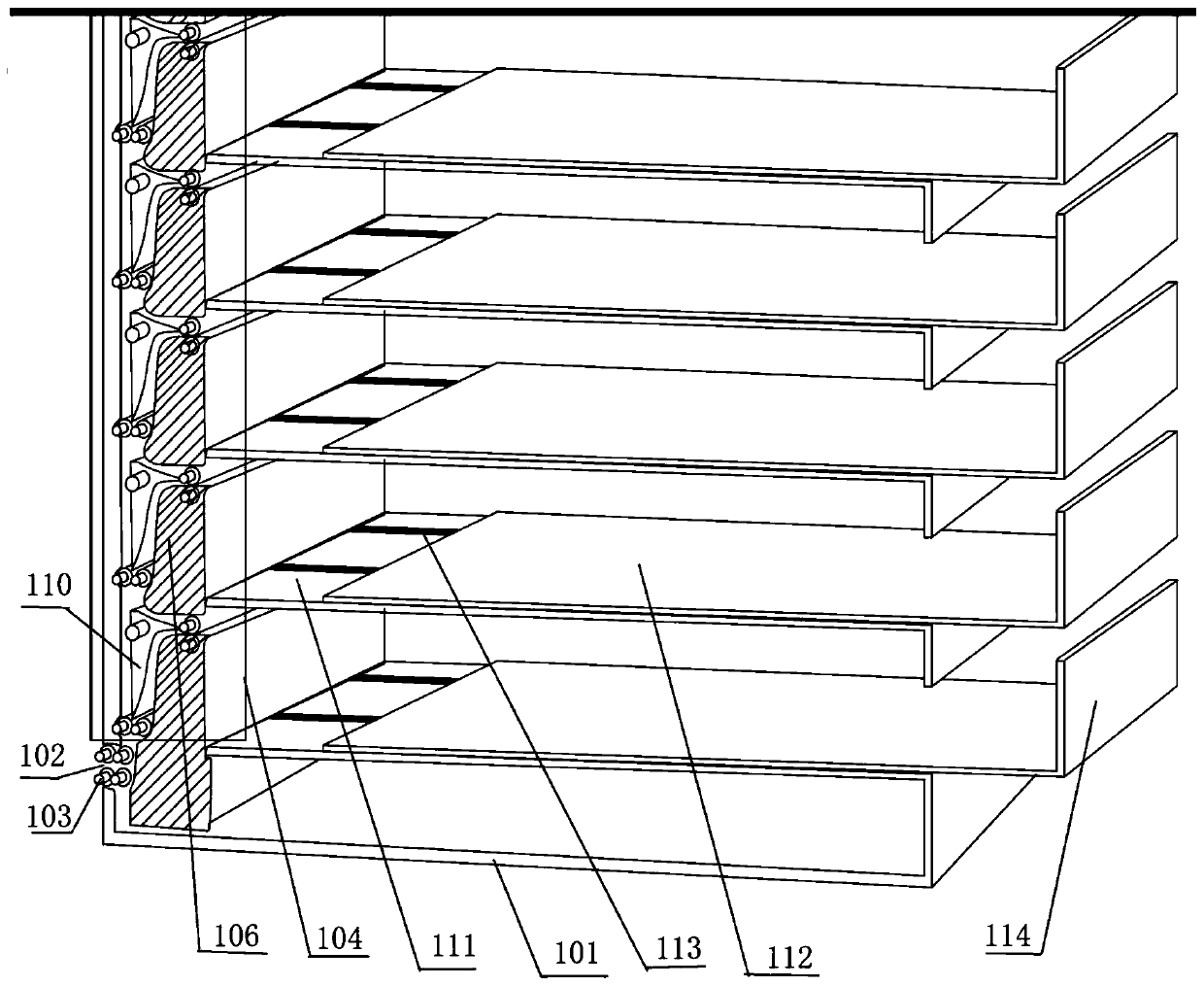

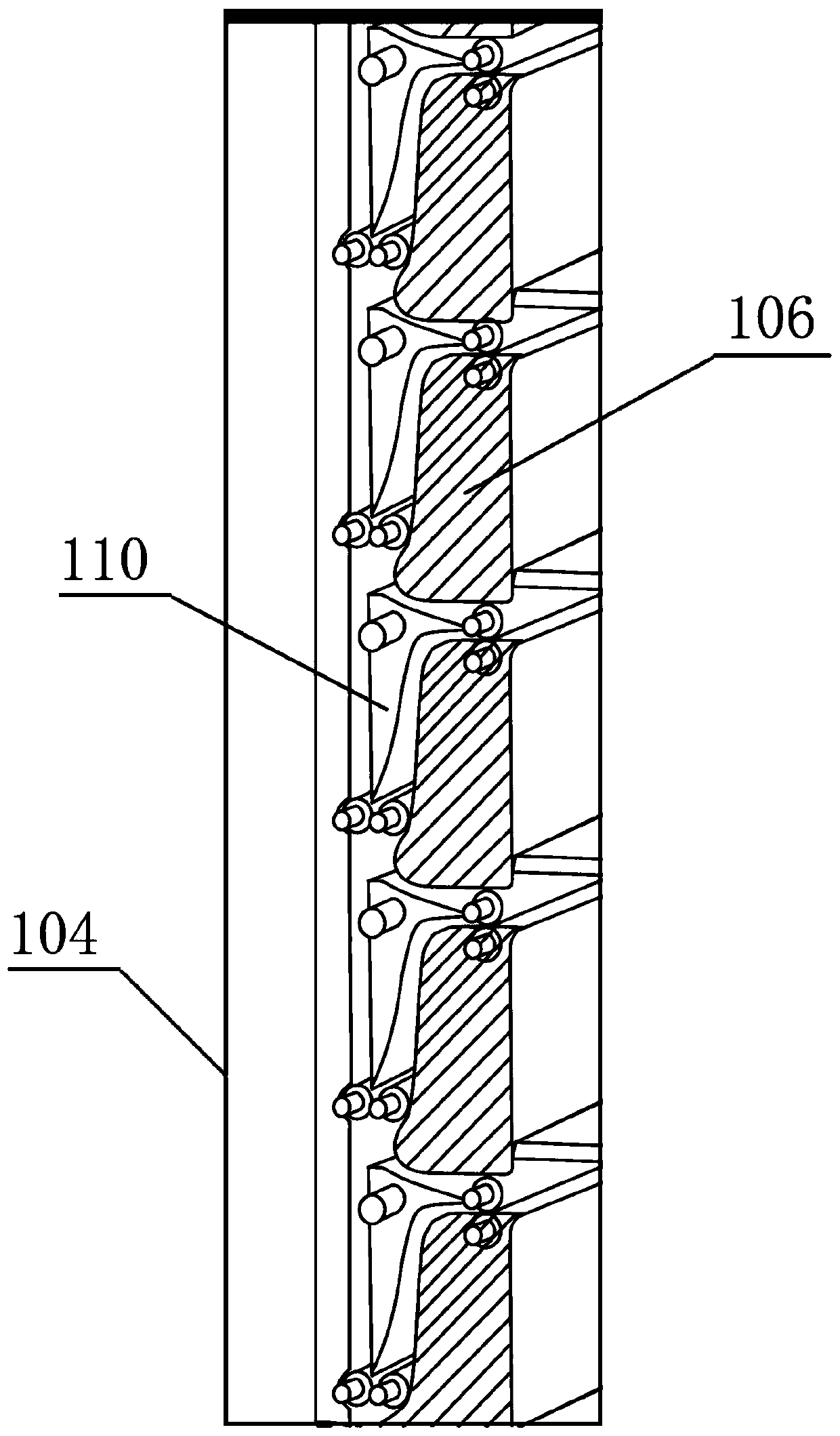

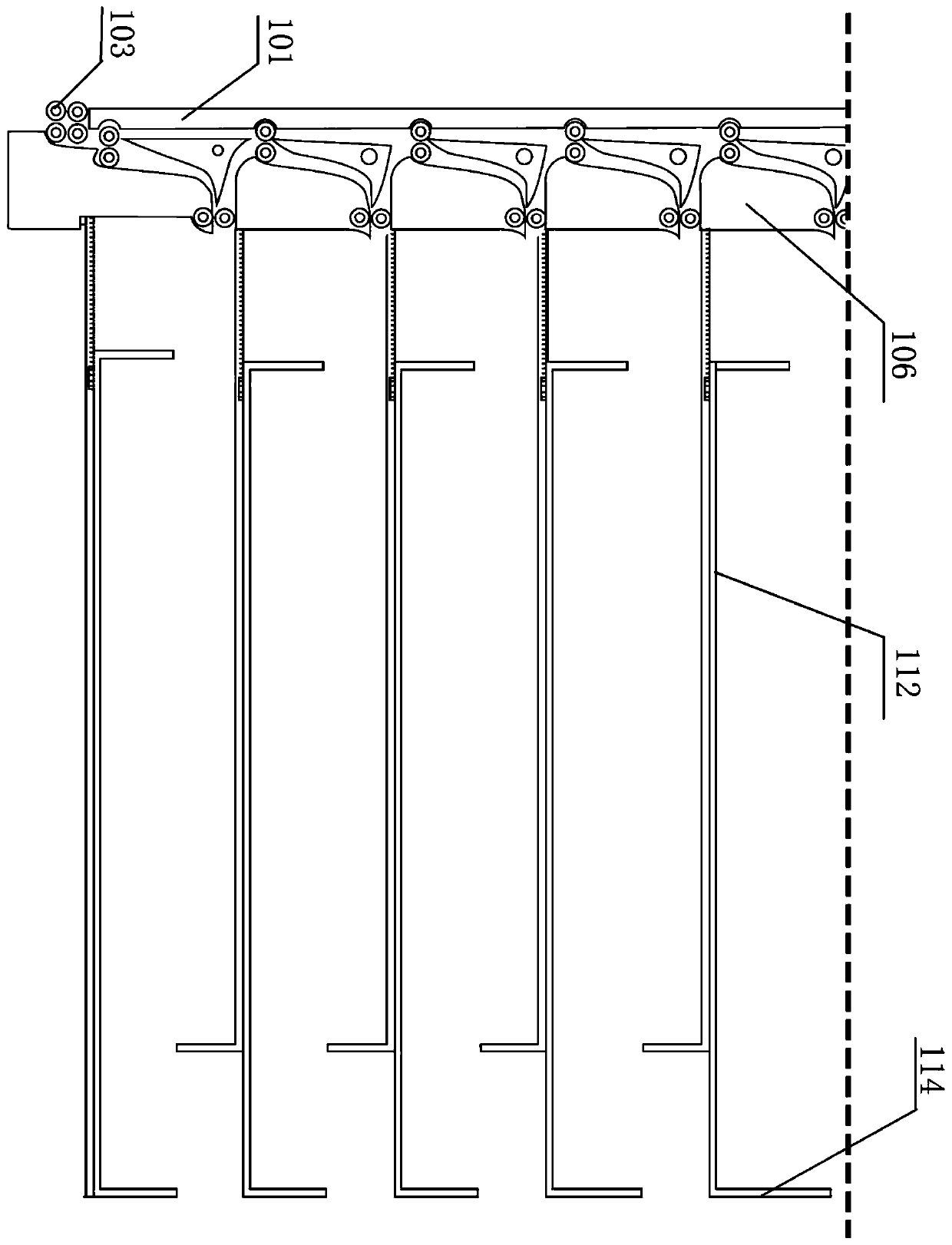

[0076] Embodiment 1: see Figure 1 to Figure 4 and Figure 13 , a multi-layer roller type automatic binding storage box, including a box body 101, the box body 101 includes a left end face, a right end face, a front side and a rear side, and the bottom of the left end face is horizontally provided with a strip-shaped paper feed Port 102, the right end face is open, and the paper inlet 102 is provided with a set of paper feed drive rollers 103, and a multi-layer transmission mechanism 104 is provided near the left end surface of the box body 101, and the multi-layer transmission mechanism 104 includes Several first single-layer conveying mechanisms 105 that are uniformly arranged from top to bottom, said first single-layer conveying mechanism 105 includes a support frame 106, a vertical conveying roller set 108 for vertically conveying paper, for A set of horizontal transfer rollers 109 and a guide mechanism 110 for horizontal transfer of paper;

[0077] The support frame 106...

Embodiment 2

[0091] Example 2: see Figure 1-Figure 8 , Figure 12 , Figure 13 . In Embodiment 2, on the basis of Embodiment 1, a side binding layer is added. That is, the function of multi-layer storage + side binding. The structure of multi-layer storage is the same as that in Embodiment 1. The structure of the side binding layer is specifically Figure 7 and Figure 8 , in this embodiment, not only a multi-layer storage area is provided in the box body 101, but also a side-side binding layer is provided;

[0092] The side binding layer includes a second horizontal base plate 201 and a second single-layer conveying mechanism 202, the second horizontal base plate 201 is the same in shape and size as the first horizontal plate, is located directly below the first horizontal base plate 111, and includes a second left edge, The second right edge, the second front edge and the second rear edge, the second single-layer conveying mechanism 202 is the same as the first single-layer conve...

Embodiment 3

[0106] Embodiment 3: see Figure 1 to Figure 13 , a multi-layer roller type automatic binding storage box, including a box body 101, the box body 101 includes a left end face, a right end face, a front side and a rear side, and the bottom of the left end face is horizontally provided with a strip-shaped paper feed mouth 102, the right end surface is open, the paper inlet 102 is provided with a group of paper feed drive rollers 103, and a multi-layer transmission mechanism 104 is arranged in the box body 101 close to the left end surface, and the multi-layer transmission mechanism 104 It includes several first single-layer conveying mechanisms 105 uniformly arranged from top to bottom, and the first single-layer conveying mechanism 105 includes a support frame 106, a vertical conveying roller set 108 for vertically conveying paper, A set of horizontal conveying rollers 109 and a guide mechanism 110 for conveying the paper horizontally;

[0107] The support frame 106 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com