Steel for vehicles with high cold bending performance and manufacturing method thereof

A manufacturing method and performance technology, applied in the field of high cold-formability automotive steel and its manufacturing, can solve problems such as poor cold-formability of steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

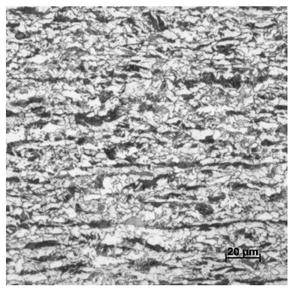

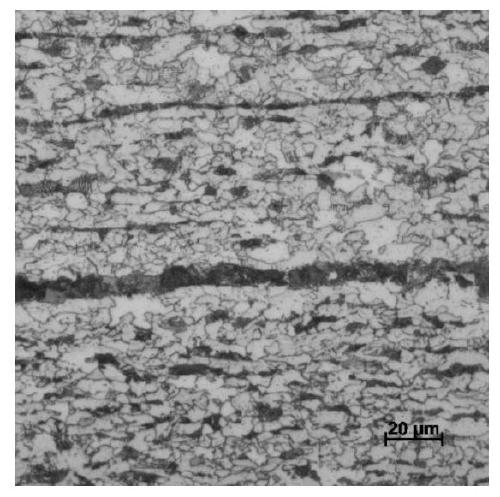

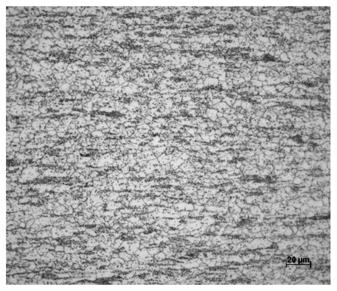

Image

Examples

Embodiment 1

[0072]Embodiments 1 to 6 select 6 groups of elements with different components for smelting respectively, wherein RE=0.025% is added by mass percentage in embodiment 1, RE=0.035% is added by mass percentage in embodiment 2, and RE=0.035% is added by mass percentage in embodiment 3. Add RE=0.037%, add RE=0.023% by mass percentage in embodiment 4, add RE=0.036% by mass percentage in embodiment 5, add RE=0.024% by mass percentage in embodiment 6, respectively each embodiment After smelting and casting slabs according to different elemental components, final products are prepared according to the process parameters in Table 2 and Table 3.

[0073] Table 2 Production Process Parameters (Part 1)

[0074] Example Baking temperature ℃ Finishing temperature ℃ Coil temperature ℃ Annealing temperature ℃ 1 1236 891 550 762 2 1235 890 551 762 3 1240 886 600 761 4 1235 888 600 762 5 1000 850 500 700 6 1250 900 600 800

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com