Connecting rod mechanism of loader

A link mechanism and a loader technology, applied in the field of lifting link mechanism and link mechanism, can solve the problems of low stability, unloading height, limited lifting of unloading distance, difficult placement and manufacture of telescopic oil cylinders, etc. The effect of improving the unloading height, excellent lifting trajectory and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments. The preferred embodiments are only to illustrate the present invention, rather than to limit the protection scope of the present invention.

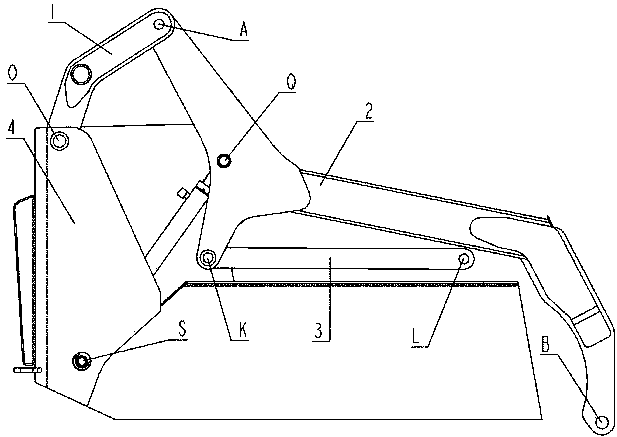

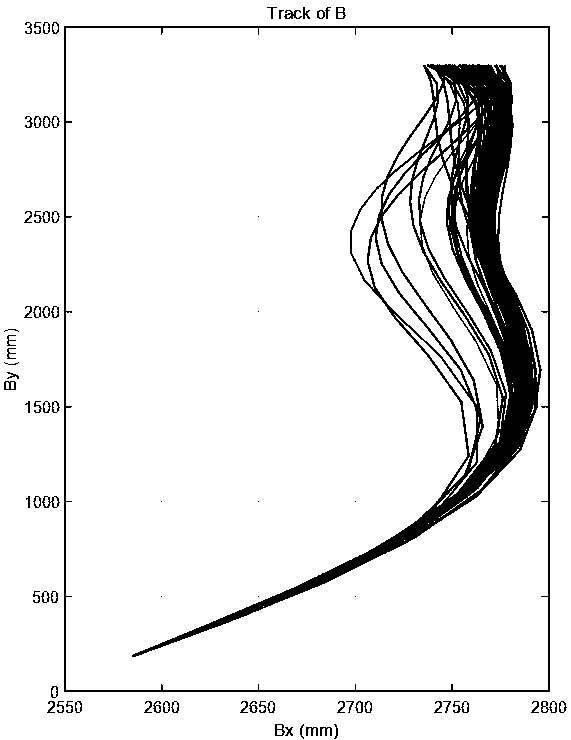

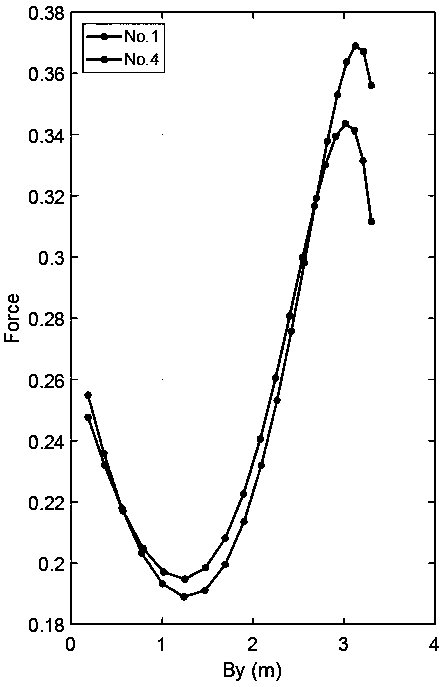

[0018] like figure 1 , figure 2 As shown, a link mechanism of a loader is placed symmetrically on both sides of the frame F, including rocker arm 1, boom 2 and pull rod 3; the rocker arm 1 and the frame 4 are hinged at point O, and The arm 2 is hinged at point A; the connection point between the boom 2 and the accessory tool is point B; the tie rod 3 and the frame 4 are hinged at point L, and the boom 2 is hinged at point K; the front of the frame 4 is The working end of the whole machine and the end where the accessory tools are located; the hinge point between the boom oil cylinder and the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com