Highly waterproof roofing system

A roof system and roof panel technology, applied in the direction of roof, roof covering, roof using flat/curved panels, etc., can solve the problems of complex structure of waterproof roof system, achieve good waterproof isolation effect, strengthen wind lift resistance, Avoid the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

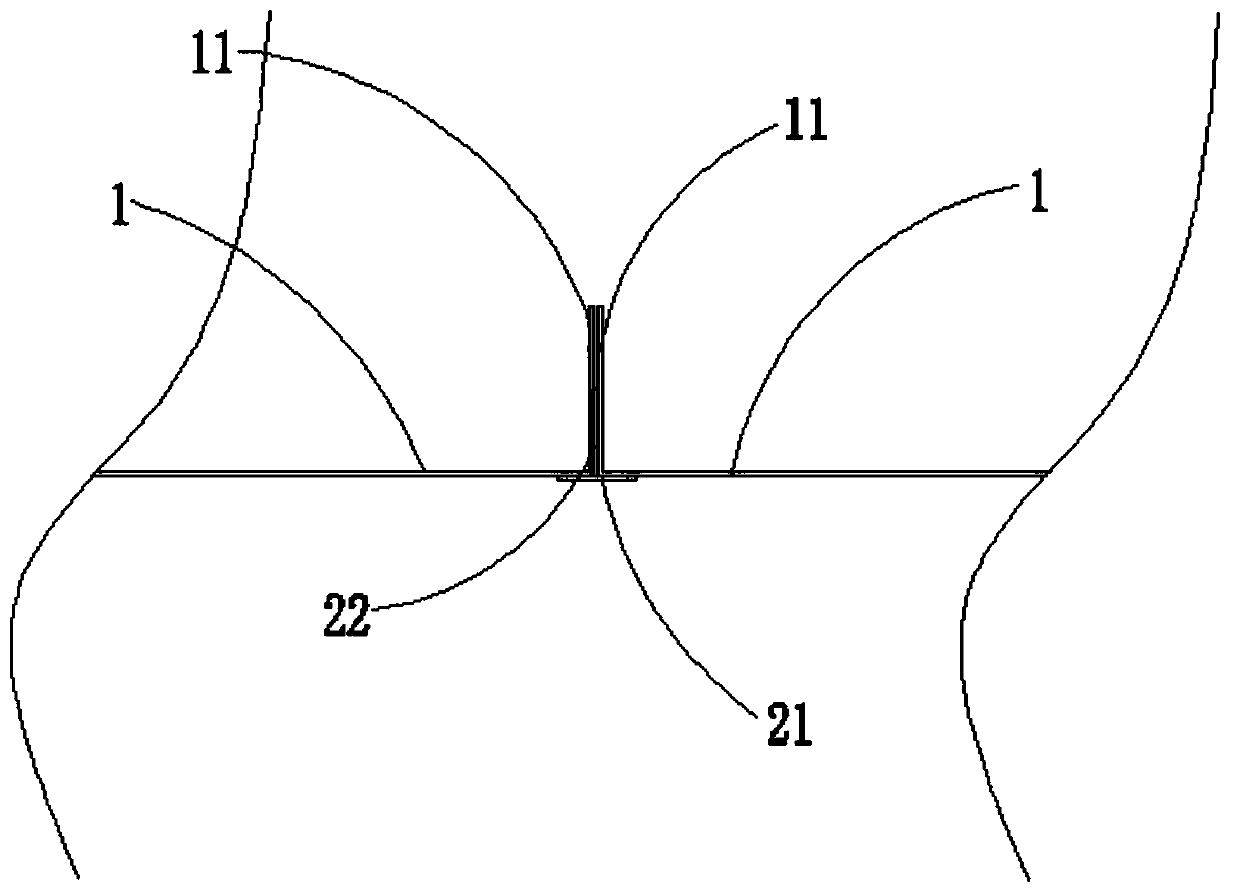

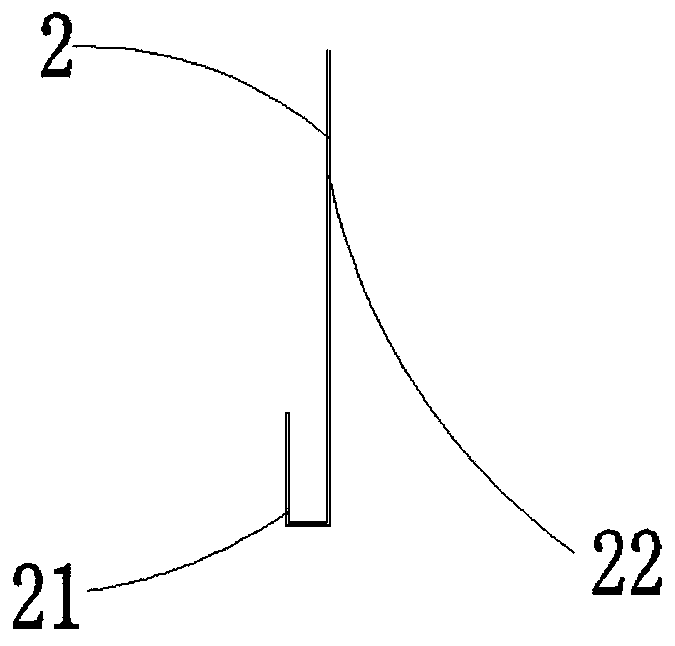

[0028] Embodiments of the present invention provide a high waterproof roof system, such as figure 1 As shown, it includes a roof panel structure. The roof panel structure is composed of several metal roof panels 1 side by side. The two sides of the metal roof panels 1 are provided with bent fixed sides 11. The adjacent metal roof panels 1 pass through The fixed sides 11 are continuously welded and fixed together, and a fixed leaf 2 is also provided between the adjacent metal roof panels 1, and the fixed leaf 2 includes a fixed seat 21 and a welding leaf 22 located on the fixed seat 21. The welding sheets 22 are welded and installed between the fixed sides 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap