Solar cell back panel insulating rubber and preparation method thereof

A technology for solar cells and insulating adhesives, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problems of affecting production efficiency, easy "overflow, slow curing speed, etc., and achieve good anti-aging." Excellent performance, electrical performance, good waterproof isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

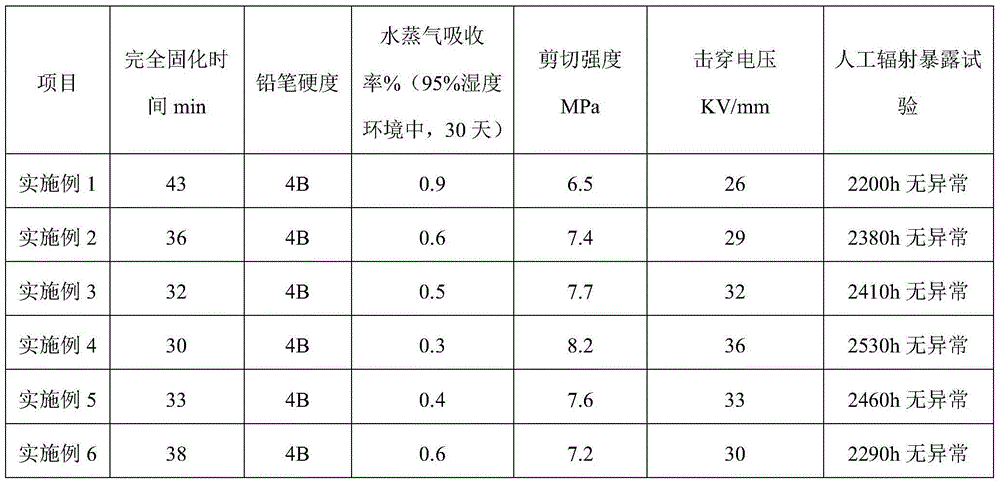

Examples

Embodiment 1

[0028] A solar cell backboard isolation glue, comprising by weight components: 20 parts of hydroxyethyl methacrylate, 5 parts of nitrile rubber, 6 parts of polyvinyl alcohol, 0.3 parts of ammonium persulfate, 6 parts of vinyl acetate, micro 3 parts of crystal wax, 4 parts of rosin glyceride, 1 part of n-butyl titanate, 2 parts of dimethyl siloxane, 2 parts of tricresyl phosphate, 1 part of barium stearate, 1 part of aluminum oxide, UV Absorbent UV-3270.3 parts, antioxidant CA0.5 parts.

[0029] The particle size of the aluminum oxide in the above components is 300 μm.

[0030] The preparation method of the solar cell backboard isolation glue comprises the following preparation steps:

[0031] (1) take each component according to parts by weight;

[0032] (2) Add each component into the reaction kettle, mix and stir evenly, then heat to 100° C. under nitrogen protection, stir and react for 60 minutes, and cool down to room temperature to obtain solar battery backplane isolati...

Embodiment 2

[0034] A solar cell backboard isolation glue, comprising by weight components: 25 parts of hydroxyethyl methacrylate, 7 parts of nitrile rubber, 8 parts of polyvinyl alcohol, 0.4 parts of ammonium persulfate, 8 parts of vinyl acetate, micro 5 parts of crystal wax, 6 parts of rosin glyceride, 2 parts of n-butyl titanate, 3 parts of dimethylsiloxane, 4 parts of tricresyl phosphate, 1 part of barium stearate, 2 parts of aluminum oxide, UV Absorbent UV-3270.5 parts, antioxidant CA0.6 parts.

[0035] The particle size of the aluminum oxide in the above components is 260 μm.

[0036] The preparation method of the solar cell backboard isolation glue comprises the following preparation steps:

[0037] (1) take each component according to parts by weight;

[0038] (2) Add each component into the reaction kettle, mix and stir evenly, then heat to 106°C under nitrogen protection, stir and react for 68 minutes at a stirring speed of 85 rpm, and cool down to room temperature to obtain a ...

Embodiment 3

[0040] A solar cell backboard isolation glue, comprising by weight components: 25 parts of hydroxyethyl methacrylate, 7 parts of nitrile rubber, 9 parts of polyvinyl alcohol, 0.6 parts of ammonium persulfate, 11 parts of vinyl acetate, micro 5 parts of crystal wax, 7 parts of rosin glyceride, 3 parts of n-butyl titanate, 4 parts of dimethyl siloxane, 5 parts of tricresyl phosphate, 1 part of barium stearate, 3 parts of aluminum oxide, UV Absorbent UV-3270.5 parts, antioxidant CA0.6 parts.

[0041] The particle size of the aluminum oxide in the above components is 250 μm.

[0042] The preparation method of the solar cell backboard isolation glue comprises the following preparation steps:

[0043] (1) take each component according to parts by weight;

[0044] (2) Add each component into the reaction kettle, mix and stir evenly, then heat to 110°C under the protection of argon, stir and react for 70 minutes at a stirring speed of 88 rpm, and cool down to room temperature to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap