Manufacturing method of standard isolation clothes

A manufacturing method and technology of isolation clothing, applied in rayon manufacturing, chemical instruments and methods, clothing, etc., can solve problems such as sweating steam cannot be discharged, breathability, poor moisture permeability, skin irritation, etc., to improve strength, Strong liquid repellency and increased air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0066] Use the above steps to prepare isolation suits, and the quality ratio of raw materials is shown in Table 1-Table 4.

[0067] Table 1: Raw material mass ratio of inner layer spunbonded fabric.

[0068] Polypropylene slices Nano calcium carbonate coupling agent Dispersant Hydrophilic additive Example 1 90 5 1 1 1 Example 2 90 10 2 1.5 2 Example 3 95 15 3 2 3 Example 4 100 20 4 2.5 4 Example 5 100 20 5 3 5

[0069] Table 2: Raw material mass ratio of the middle layer meltblown cloth.

[0070] Nano silica: coupling agent Polypropylene chips: Nano silica Example 1 100:1 100:0.1 Example 2 100:2 100:0.2 Example 3 100:3 100:0.3 Example 4 100:4 100:0.4 Example 5 100:5 100:0.5

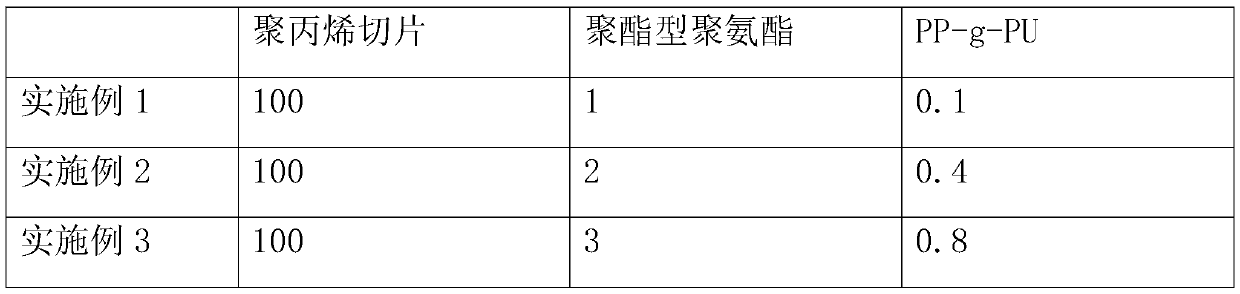

[0071] Table 3: Raw material mass ratio of the outer spunbonded fabric.

[0072]

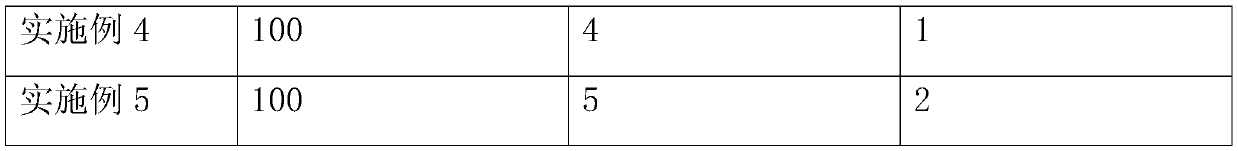

[0073]

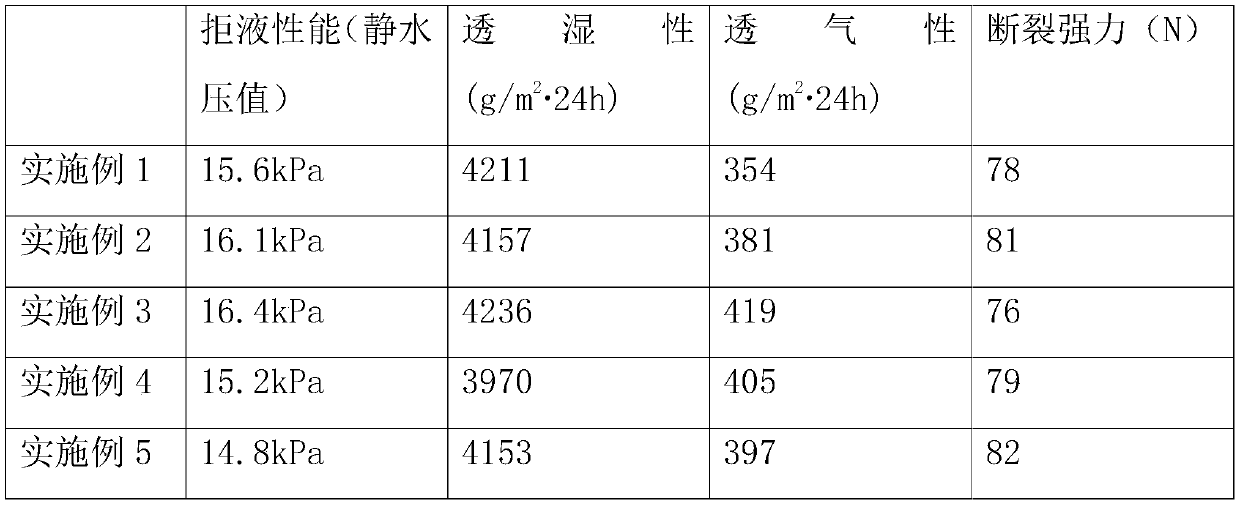

[0074] Table 4: Ratio of raw materials in parts by mass of the impregnating solu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap