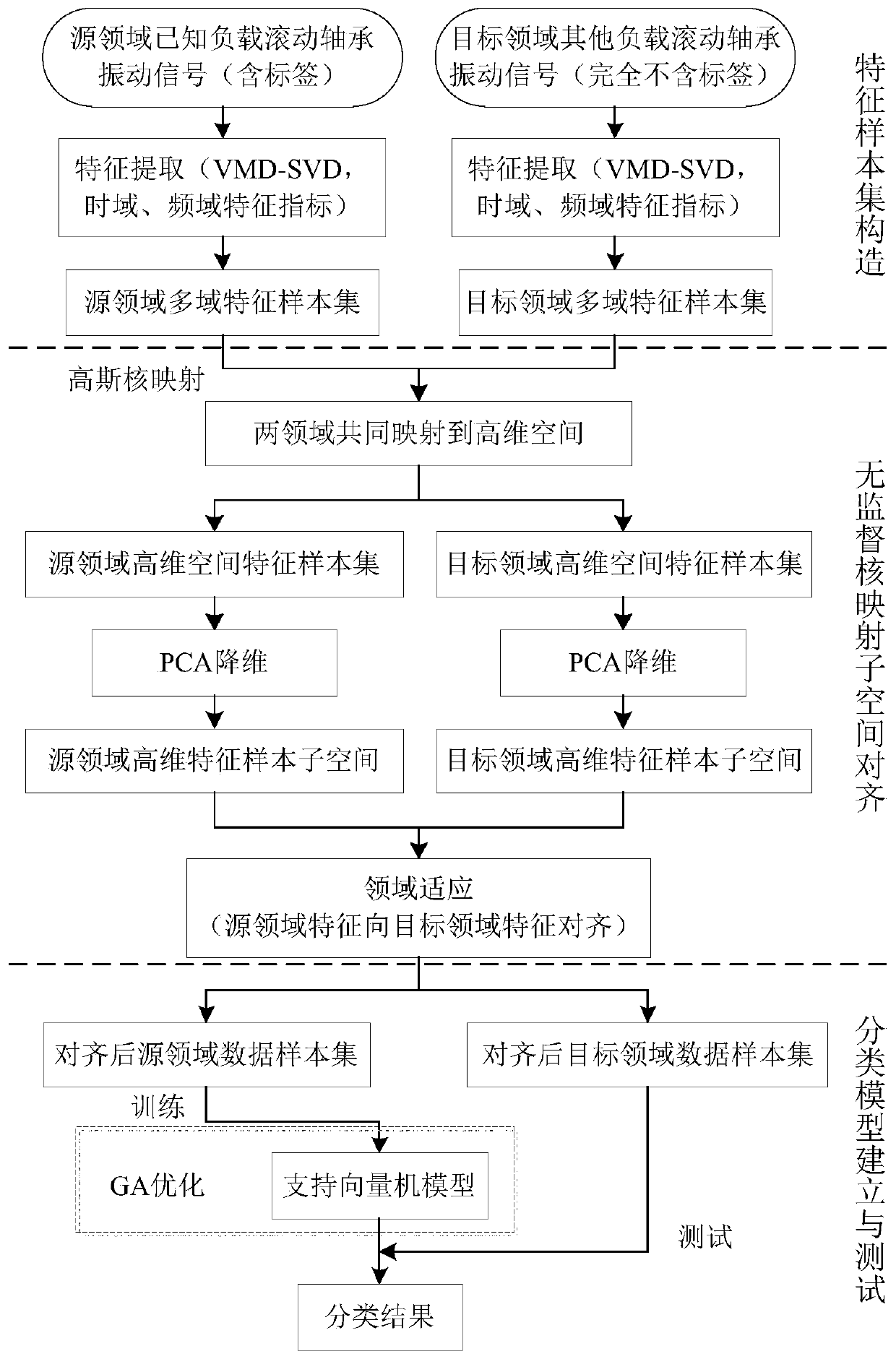

Rolling bearing fault diagnosis method under variable-load based on unsupervised characteristic alignment

A rolling bearing and fault diagnosis technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of samples in the target field without labels, lack of load data, etc., to achieve high fault diagnosis accuracy, increase the discriminative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] For the realization of the method of the present invention in conjunction with Figures 1 to 7 Explain as follows:

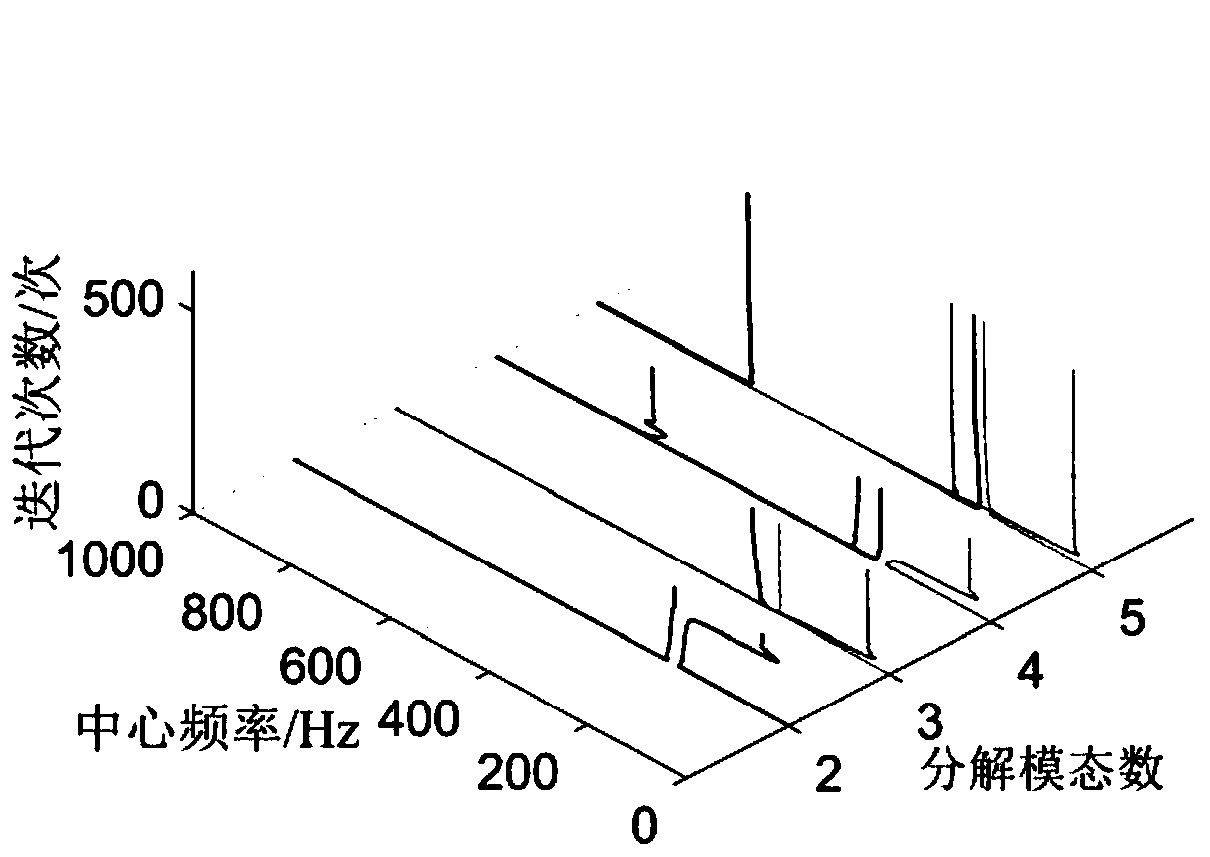

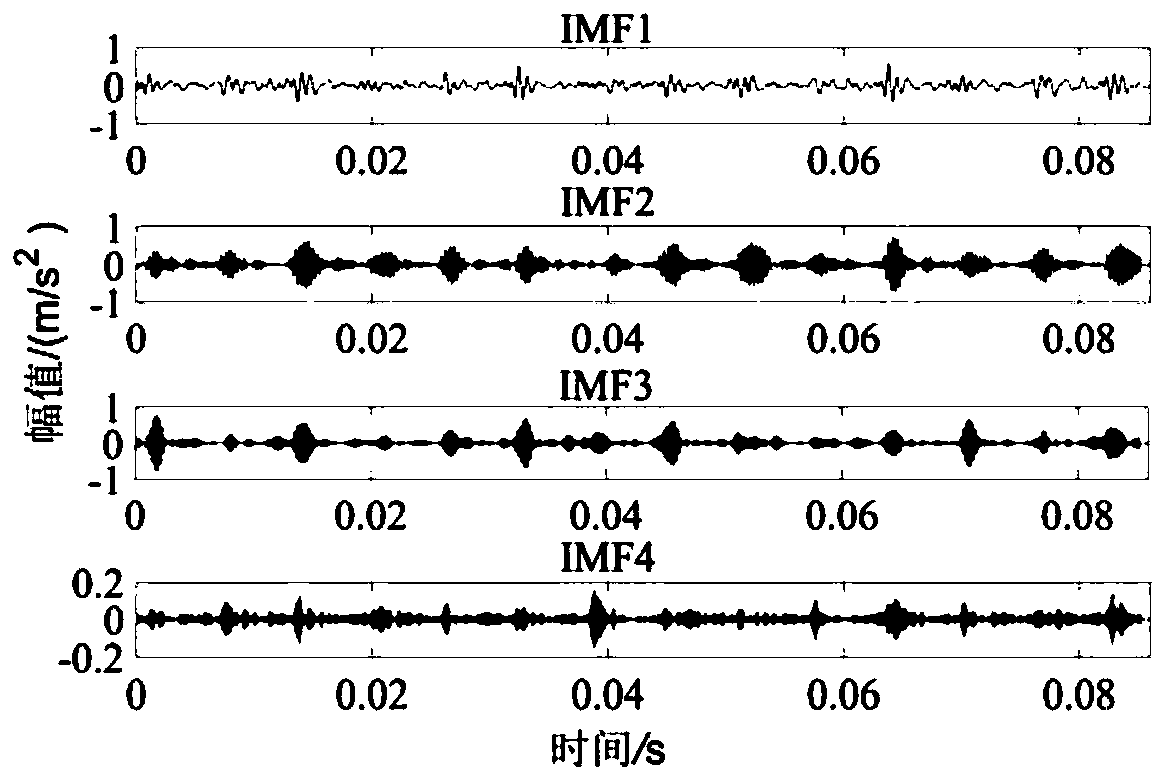

[0044] 1 Principle of variational mode decomposition

[0045] Variational mode decomposition is a completely non-recursive, adaptive signal processing method, and the overall framework of the method is a variational problem. Assuming that each mode has a finite bandwidth with a different center frequency, the goal is to minimize the sum of the estimated bandwidths of each mode, which is the input signal. The process of continuously updating the center frequency and bandwidth during the decomposition process can be divided into the construction and solution of the variational problem.

[0046] 1.1 Construction of variational problems

[0047] 1) For each modal function u k (t) Carry out the Hilbert transform to obtain the analytical signal of each modal function:

[0048]

[0049] 2) Modulate the spectrum of each mode to the corresponding baseband:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com