Automobile tire blowout test device

A technology for automobile tires and test devices, applied in the direction of automobile tire testing, etc., can solve the problems of general reliability, large size of the device, difficult to use the tire burst test, etc., and achieve the effects of good compatibility, small size, and low processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the working process of the present invention will be further described.

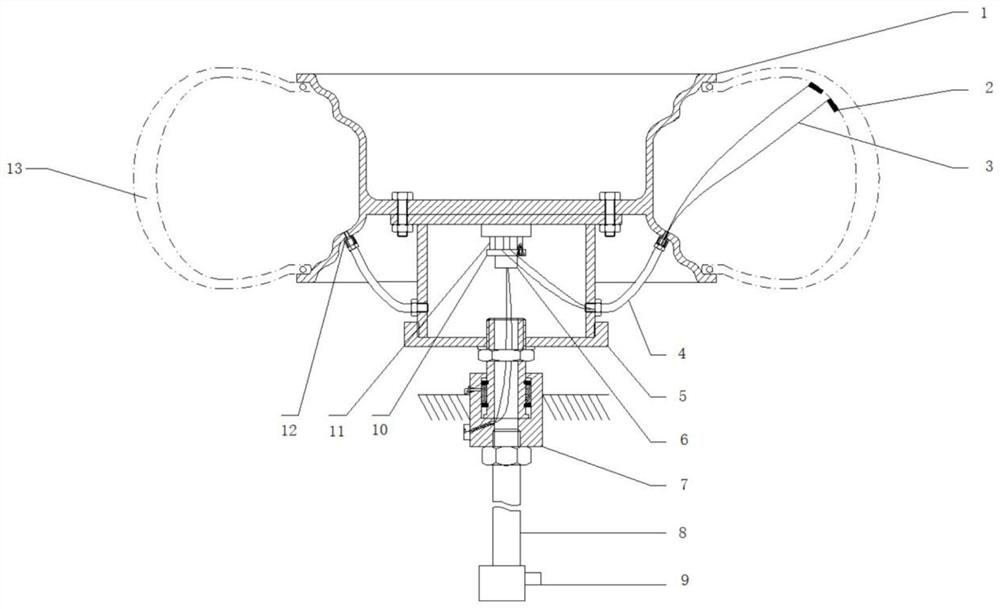

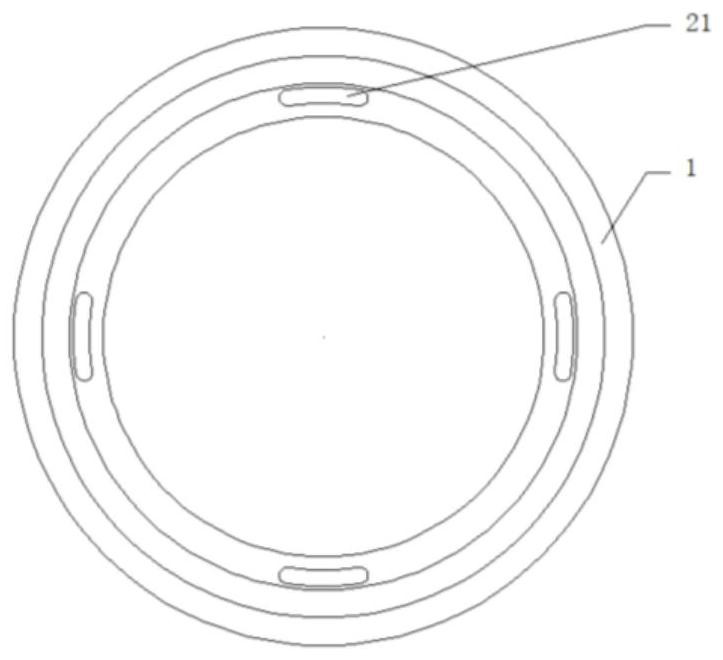

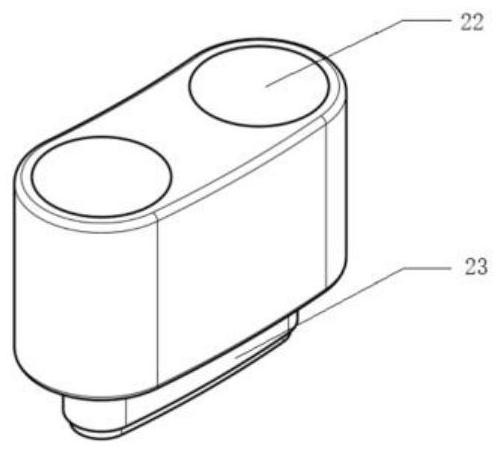

[0032] Such as figure 1 As shown, a kind of automobile tire puncture test device provided by the present invention comprises wheel hub 1, parameter detection sensor 2, lead wire 3, air intake pipe 4 with quick joints at both ends, air collection chamber 5, slip ring stator 6, rotating Joint 7, air pipe 8 with rotary joint, air release valve 9, slip ring 10, slip ring support 11, arc-shaped integrated conversion joint 12 and tire 13. The gas collection chamber 5 passes through such as figure 1 the first way or if Figure 5 The two ways of the second way are fixedly connected with the wheel hub.

[0033] figure 1 The first installation mode of the air collecting chamber 5 is schematically drawn in . In this installation method, holes are drilled on the spokes of the wheel hub 1 and the edge flange of the air collecting chamber 5, and the two parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com