Device and method for detection of inter-turn state of large motor stator winding

A technology for stator windings and large motors, which is applied in the direction of electric winding testing, measuring devices, measuring electricity, etc. It can solve the problem that there is no theory and corresponding detection means for the basic phase-phase coupling magnetic field, and it is impossible to achieve accurate state positioning detection of motor windings throughout the life cycle , Rough detection of inter-turn defects in windings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

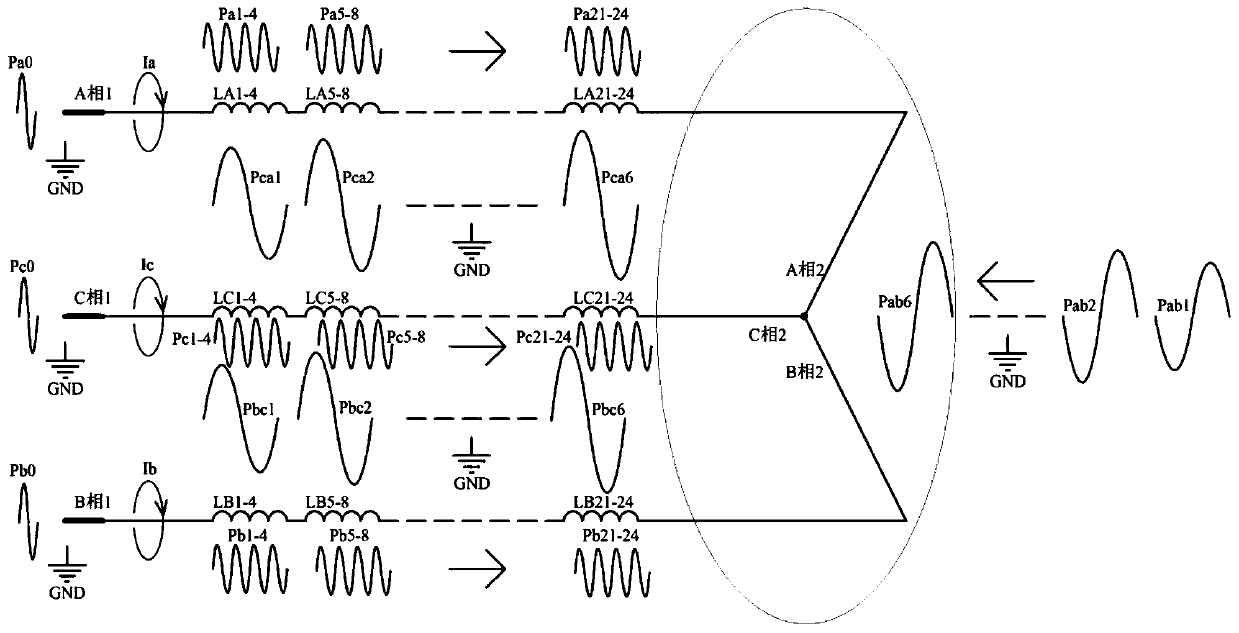

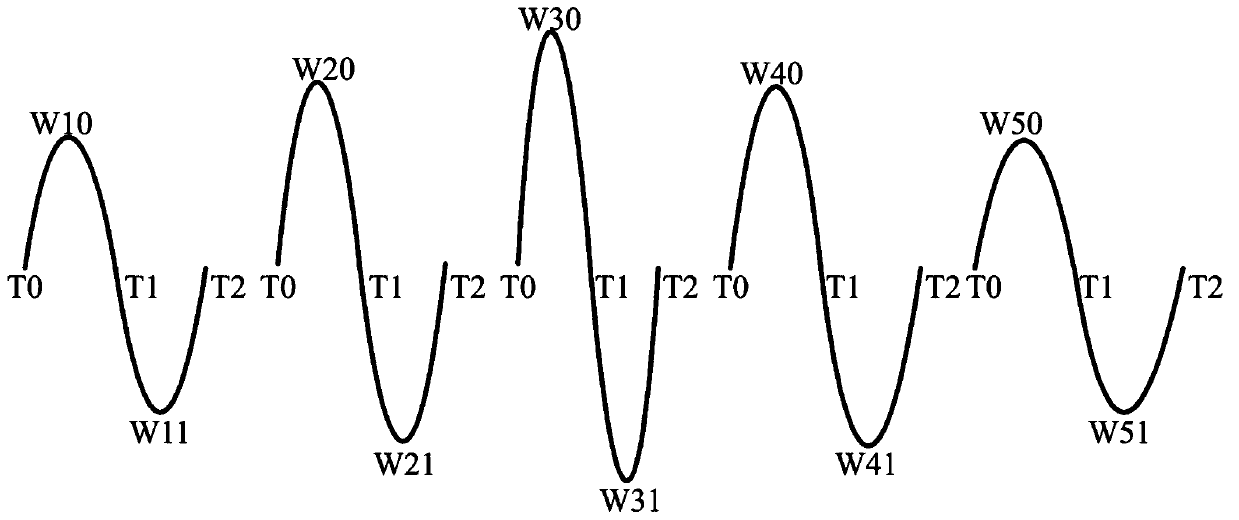

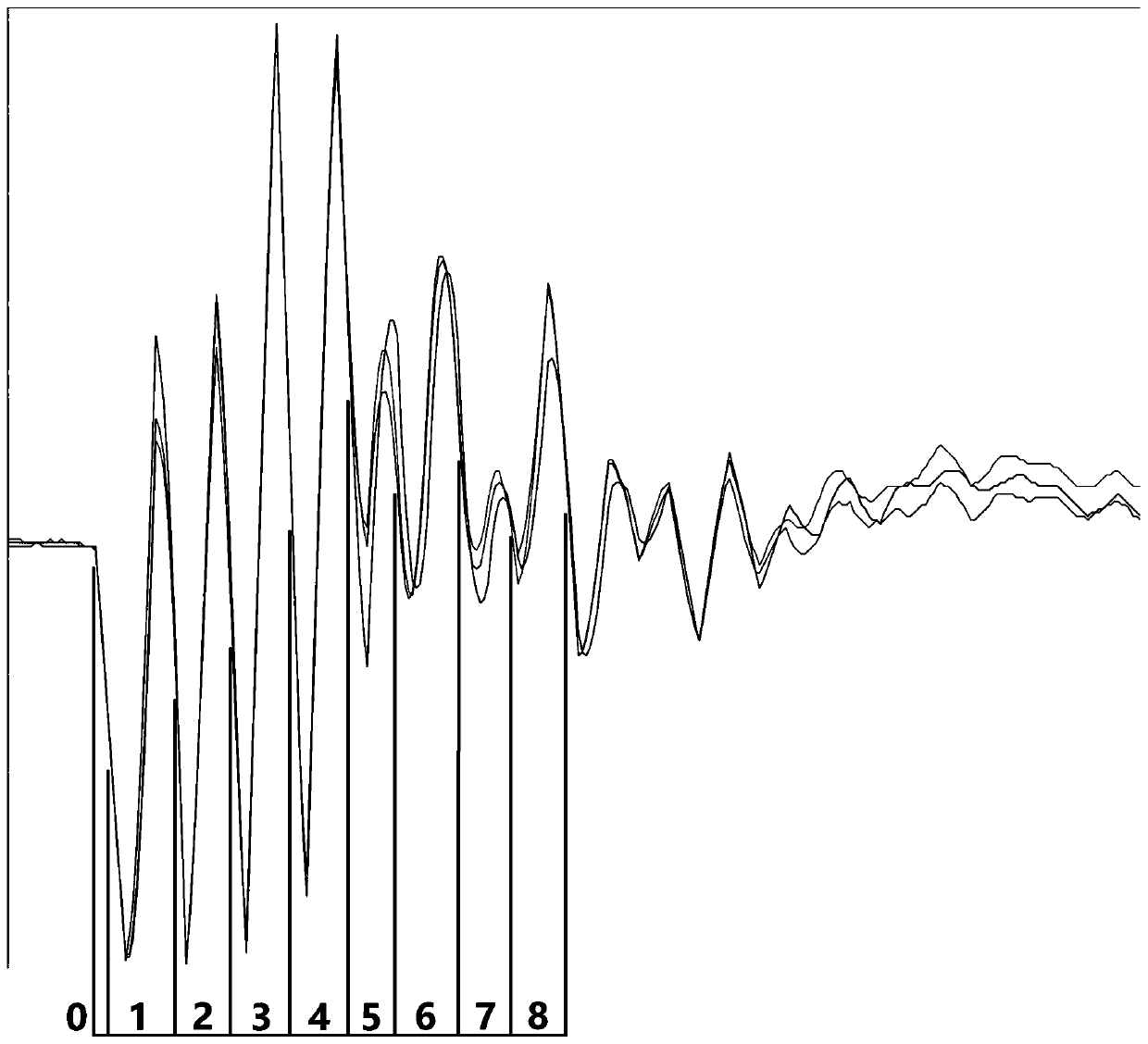

[0031] Referring to the accompanying drawings of the description, the present invention provides a device and method for detecting the inter-turn state of a stator winding of a large motor. Circuit, synchronous current pulse to voltage pulse function circuit, data acquisition system, host computer management system, waveform data analysis system;

[0032] The central processing unit controls the transient sequence circuit to generate a transient voltage pulse, and the transient sequence circuit is connected to the driving and transducing matching circuit, and the driving and transducing matching circuit converts the transient voltage pulse into corresponding double positive transient State magnetic field current pulse, the driving and energy conversion matching circuit connects the double positive transient magnetic field current pulse to the power supply end of the adjacent phase of the stator winding and the reference terminal of the stator core through the current impedance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com