Air-blowing, cooling and dust-removal power distribution cabinet

A power distribution cabinet and power technology, which is applied in the substation/distribution device casing, electrical components, substation/switch layout details, etc. Wind, improve dust removal effect, reduce temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

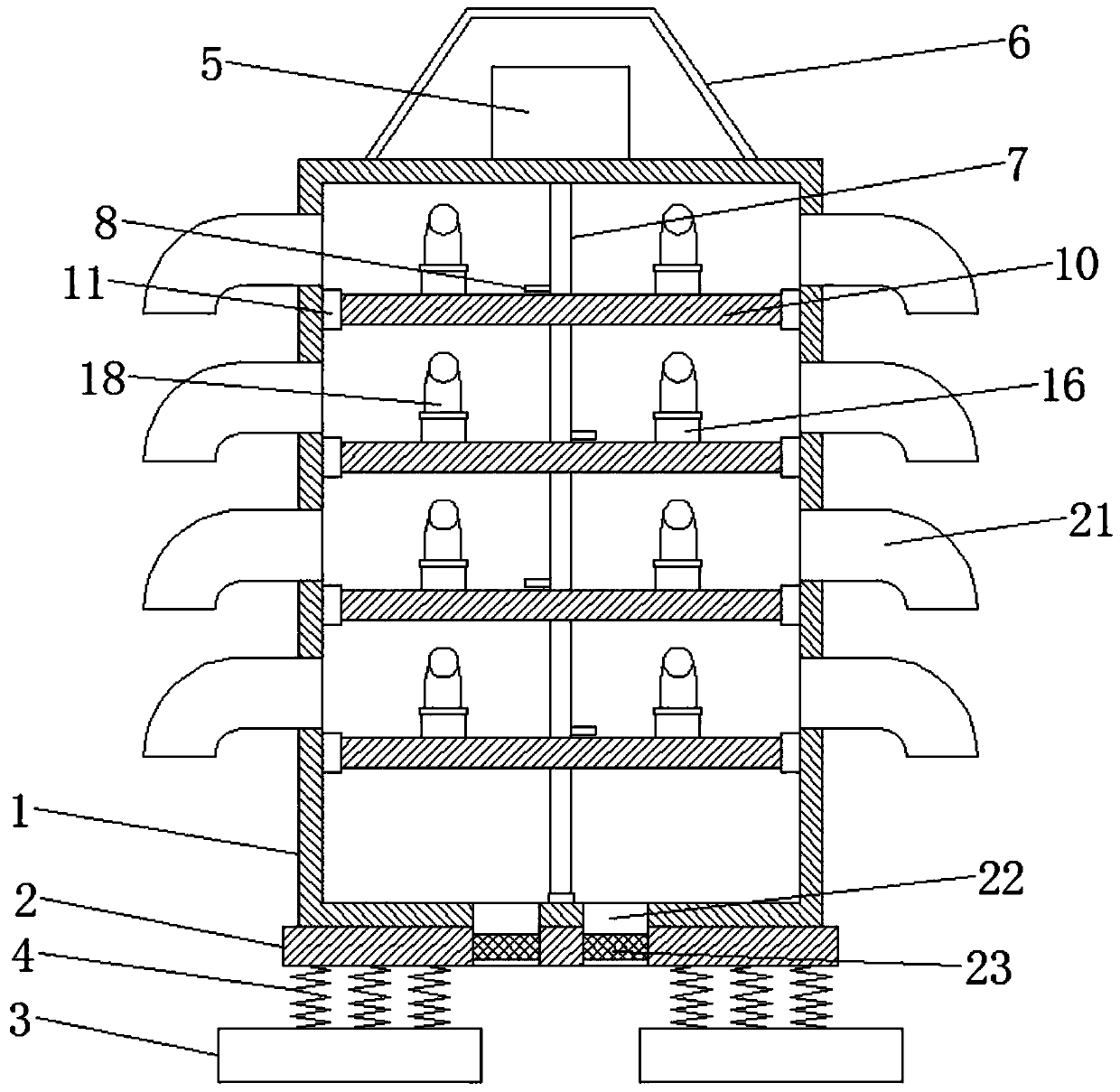

[0020] Please refer to the figure, in the embodiment of the present invention, a power distribution cabinet for blowing, cooling and dust removal includes a cabinet body 1, a base 2, a fixing seat 3 and a shock absorbing spring 4; the base 2 is fixedly welded on the cabinet body 1 At the bottom, a horizontal fixed seat 3 is provided below the base 2, and the fixed seat 3 is fixed on the ground by expansion bolts, and several shock absorbing springs 4 are fixedly installed between the base 2 and the fixed seat 3, and the shock absorbing spring 4 Connect the base 2 and the fixed seat 3 to play a role of shock absorption and buffering thereon.

[0021] A vertically downward motor 5 is fixed on the top of the cabinet 1, and a vertical shaft 7 is fixedly connected to the lower end of the output shaft of the motor 5, and the shaft 7 extends downward to the bottom of the cabinet 1 and is rotatably connected by a bearing. , the outer cover of the motor 5 is provided with a protective ...

Embodiment 2

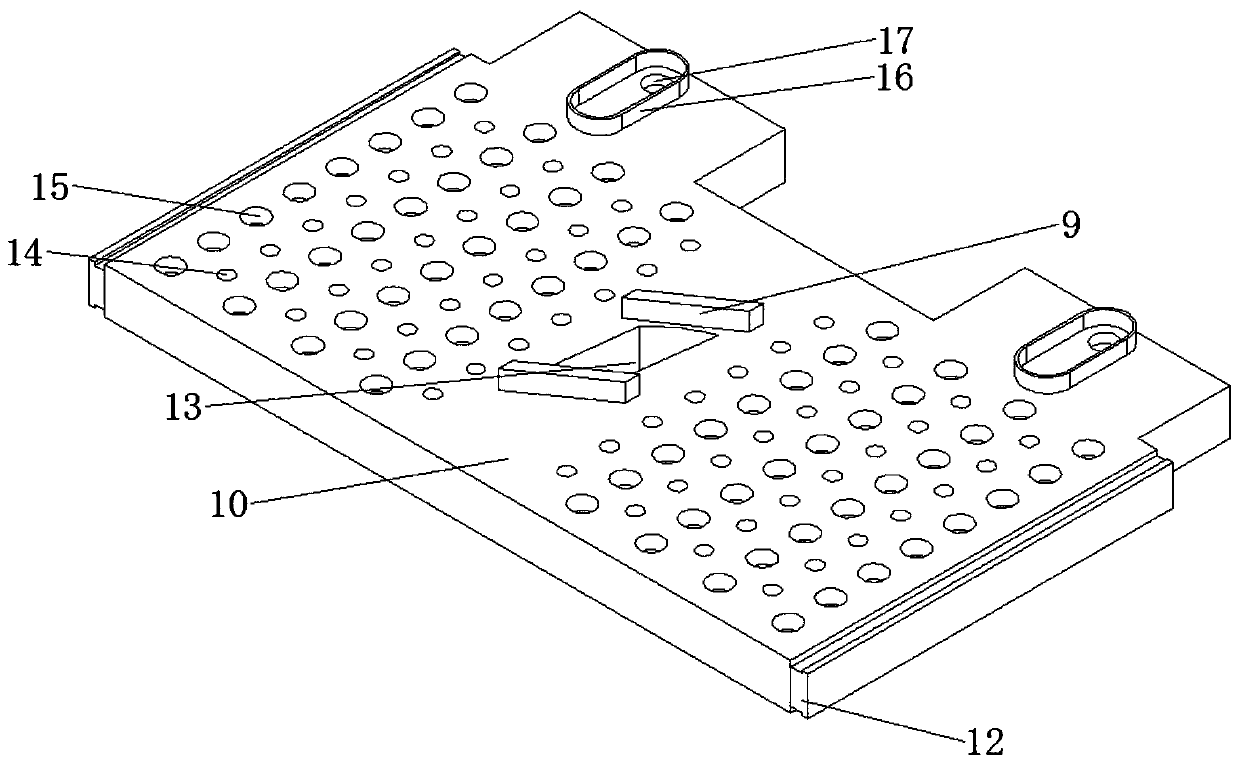

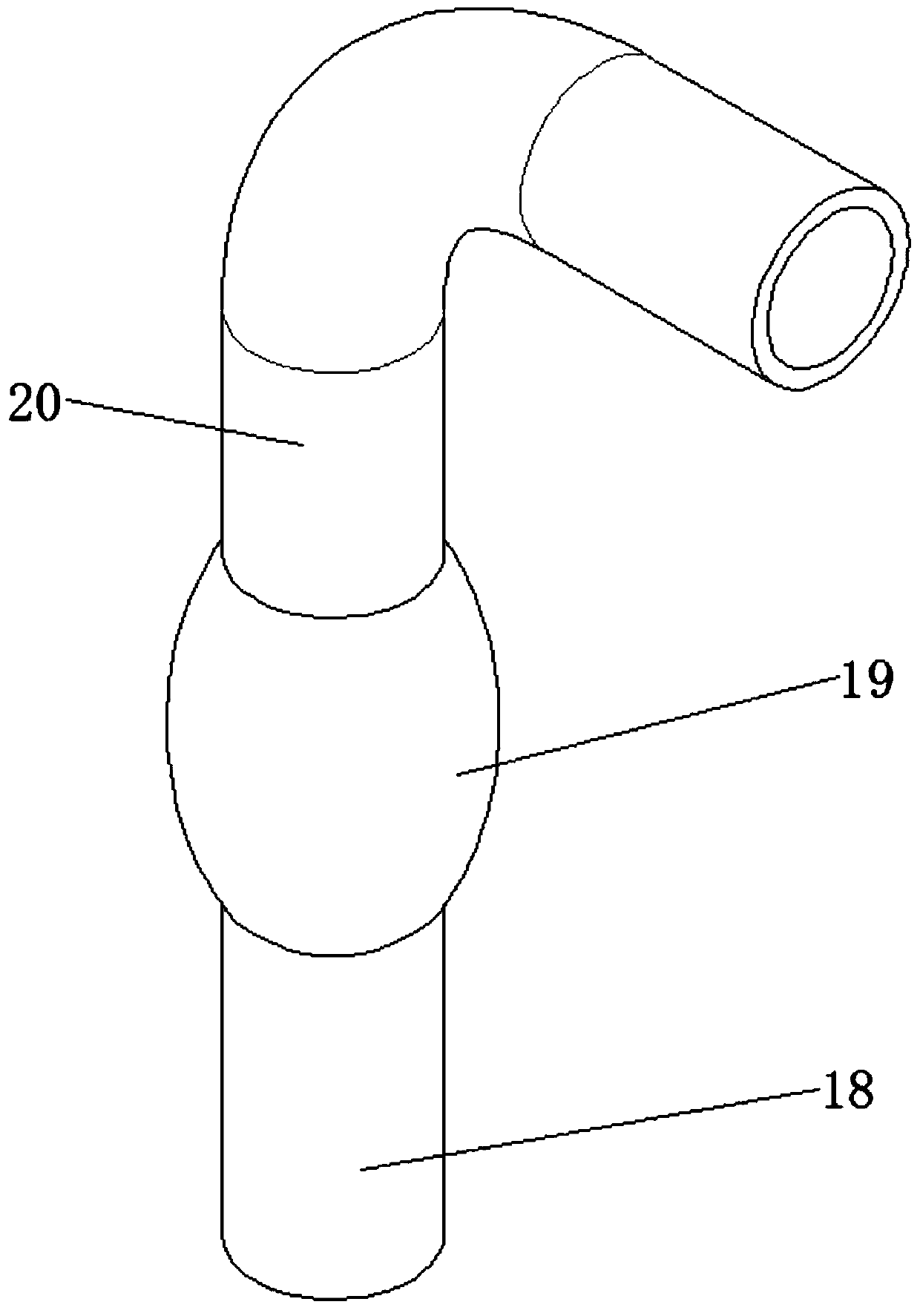

[0024] On the basis of Embodiment 1, preferably, the branch pipe 20 is provided with two, the lower end of the branch pipe 20 communicates with a vertically downward air inlet pipe 18, and the outer wall of the air inlet pipe 18 is covered with an airbag 19, And offer some holes on the side wall of the air inlet pipe 18 to communicate with the air bag 19, so that the air in the air inlet pipe 18 can enter the air bag 19 to expand the air bag 19; The upper surface of 10 is fixed with a horizontal sliding sealing groove 16, the sliding sealing groove 16 has an oval structure and is distributed along the front and rear directions, the lower end of the air inlet pipe 18 extends into the sliding sealing groove 16, and is connected with the sliding sealing groove 16. There is a gap at the bottom, and the distance is 0.2-0.4mm; a connecting hole 17 is provided on one end of the bottom in the sliding sealing groove 16, and the partition 10 is a hollow structure, and the connecting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com