Construction method of rapid installation and dismantling of hanging formwork system for integral pouring of inspection well circle

A technology of integral pouring and construction method, which is applied in construction, artificial islands, water conservancy projects, etc. It can solve the problems of easy cracking at the joint between the road surface and the well circle, poor integrity and durability of the road surface, and many processes, so as to meet the conditions and conditions of use. Improve and increase the impact resistance and compression resistance, and the effect of firm assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

[0045] The purpose of the present invention is to simultaneously cast the base 30 of the concrete pavement and the cast-in-place well circle 22 above the shaft 24 on the roadbed 25 with the manhole.

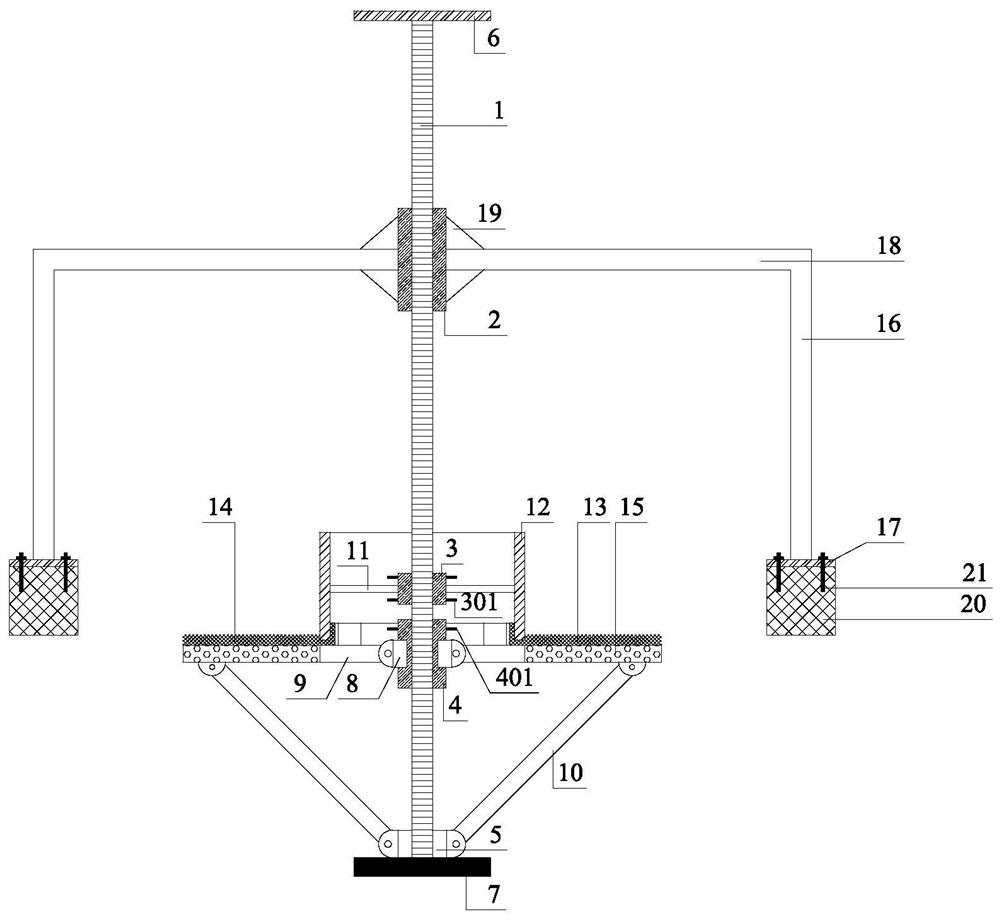

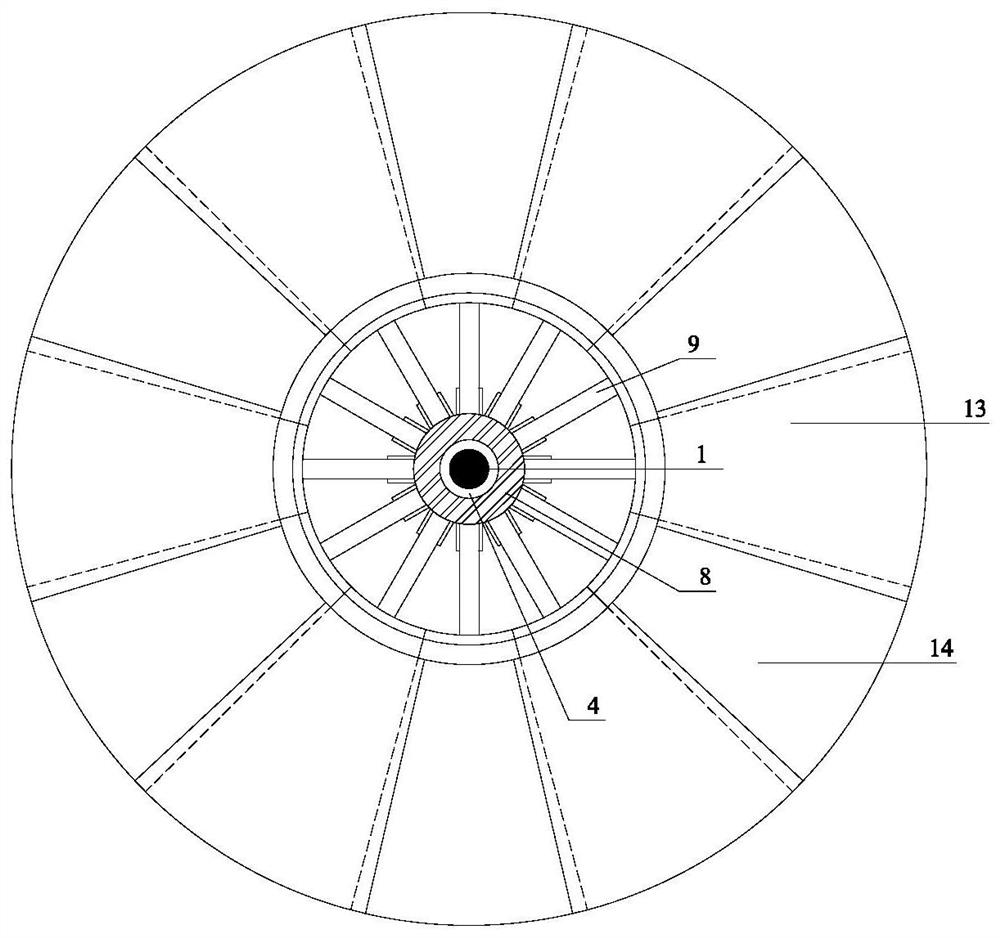

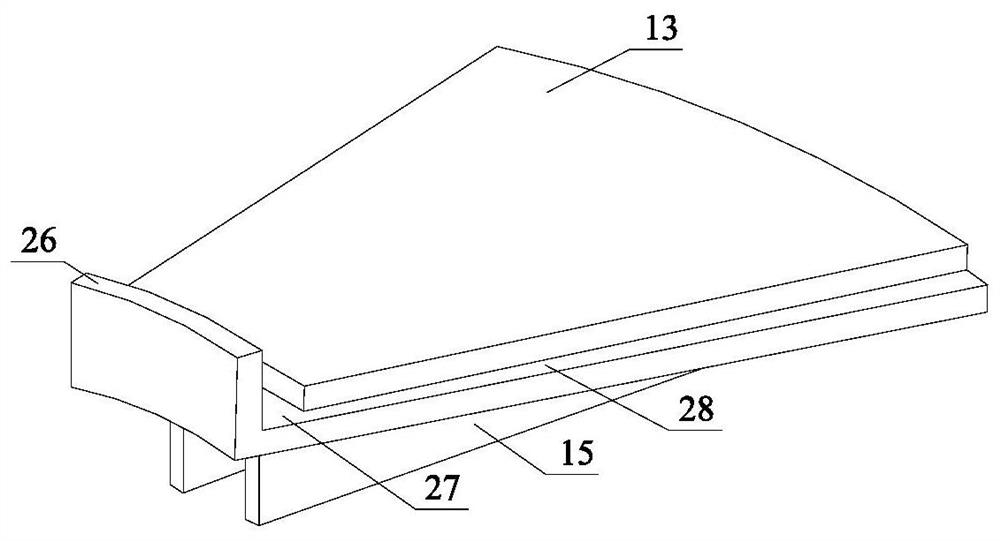

[0046] combined with figure 1 As shown, the present invention relates to a rapid installation and disassembly hanging formwork system for integral pouring of inspection well rings, including a support structure, a screw 1, a bottom form support structure, a bottom form, a side form support structure and a side form cylinder 12 . The support structure includes a threaded sleeve A2 and an L-shaped support. There are several groups of L-shaped supports arranged evenly on the outer ring of the threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com