Suspending device for preventing rotary guiding tool from falling into well

A suspension device and rotary steering technology, applied to rotary drilling rigs, drilling equipment, drilling equipment and methods, etc., can solve the problems of universal joint fatigue failure and other problems, achieve easy selection and installation, facilitate workshop assembly, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by implementing method and accompanying drawing, the present invention is described in further detail:

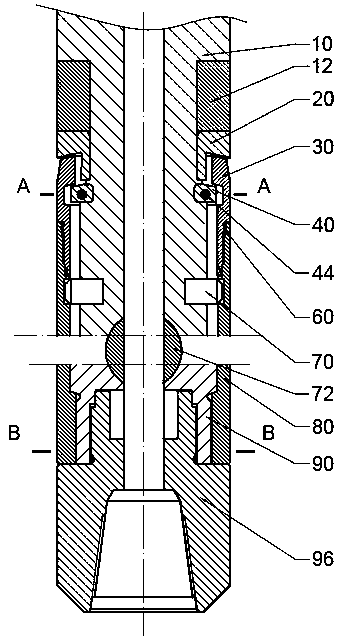

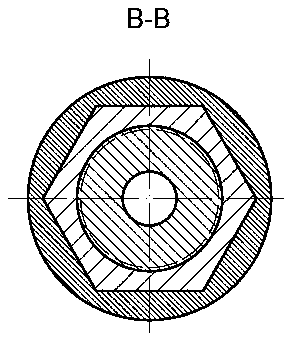

[0022] An anti-fall suspension device for a rotary steerable tool such as Figure 1-Figure 5 As shown, it mainly includes tool upper body system, tool lower body system, suspension system and universal joint.

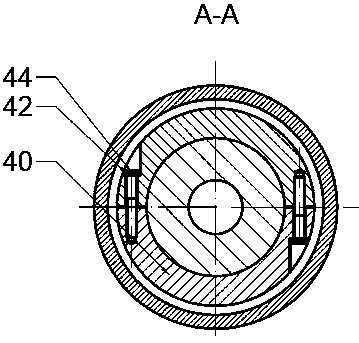

[0023] First, the tool body 10 is prepared, the universal joint 72 is installed, and the tool body 10 is connected with the lower body 90 of the universal joint to realize the preliminary connection of the upper and lower body systems of the tool; In the uppermost end (the actual assembly is lying flat on the support frame), two screws 44 and spring washers 42 are used to install the two suspension frames 40 on the tool body 10 as shown in the figure. At this time, the overcoat 30 will be suspended Moving downwards, the steps on the inner wall contact the suspension frame to complete the preliminary assembly of the suspension device; then the pushed out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com