a submersible pump

A submersible pump and pump body technology, applied in the pump, pump components, pump control and other directions, can solve the problems of low adaptability, adjust the position and lift of the drain pipe, etc., achieve high adaptability, easy and convenient installation process, increase The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

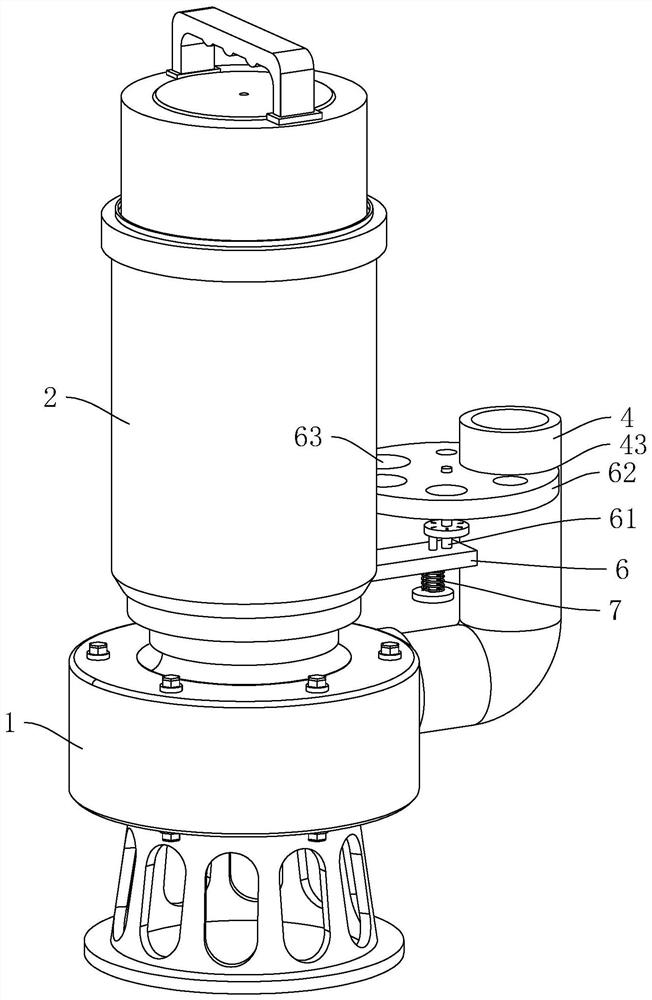

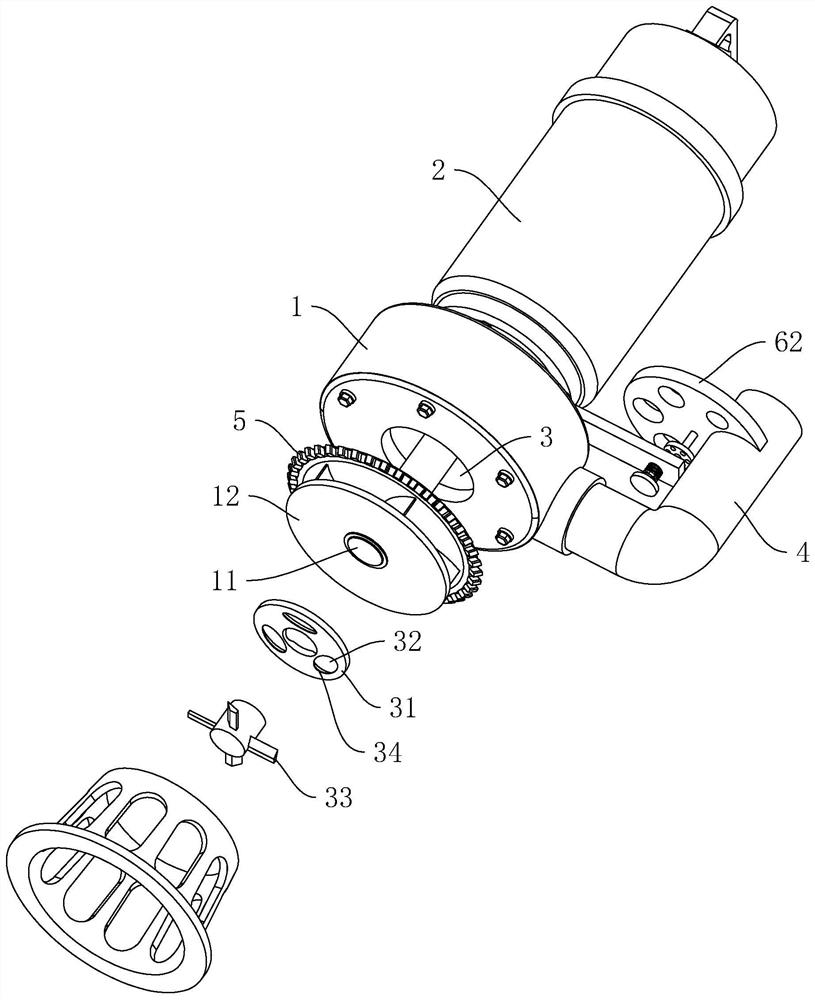

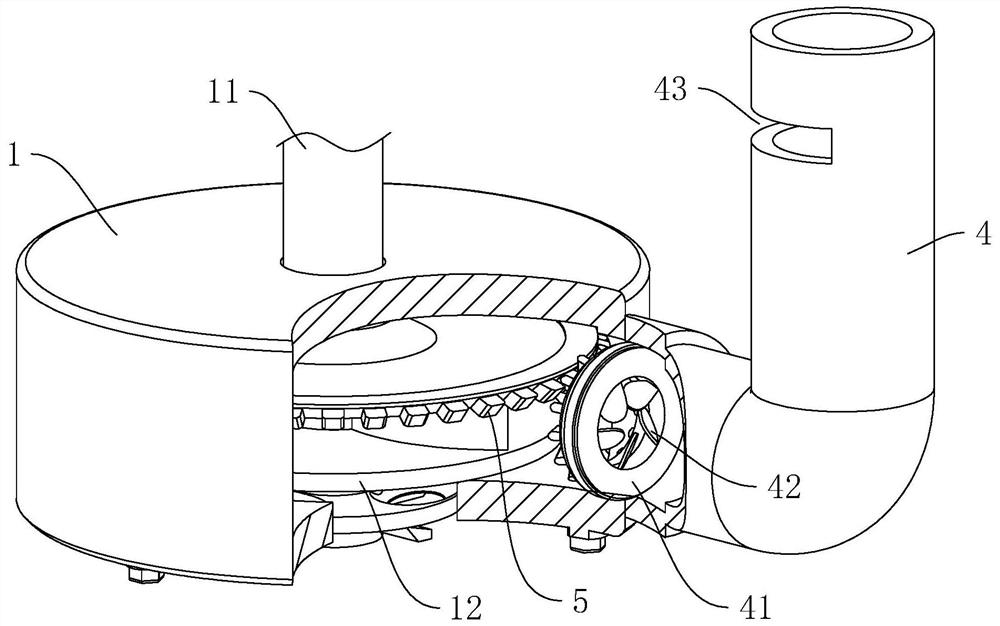

[0036] Embodiment 1: as figure 1 , figure 2 As shown, a submersible pump includes a pump body 1 and a motor 2. A pump shaft 11 is connected to the pump body 1 for vertical rotation. The pump shaft 11 is provided with an impeller 12 located in the pump body 1. The lower end surface of the pump body 1 A water inlet 3 is provided, and a drainpipe 4 connected to the inside is arranged on the side wall bent upward.

[0037] When the above-mentioned submersible pump is in use, the motor 2 is used to drive the pump shaft 11 to rotate. At this time, the pump shaft 11 drives the impeller 12 to rotate synchronously, and the water flow is sucked into the pump body 1 along the water inlet 3, and then the water flow is drawn along the drain pipe. 4 discharge, realize the suction and discharge of water flow.

[0038] like figure 2 As shown, a cutting disc 31 is horizontally arranged in the water inlet 3 , and a plurality of water inlet holes 32 run through the cutting disc 31 . A cutt...

Embodiment 2

[0053] Embodiment 2: as Figure 5 As shown, a submersible pump differs from Embodiment 1 in that a mounting ring 44 is provided on the outer wall of the upper end of the drain pipe 4, and a mounting sleeve 45 is provided on the upper end surface of the mounting ring 44, and the outer wall of the drain pipe 4 and the mounting sleeve 45 An installation gap 46 is formed between the inner walls, and a viewing hole 451 communicating with the installation gap 46 runs through the outer wall at the lower end of the installation sleeve 45 .

[0054] like Figure 5 As shown, the outer wall of the upper end of the drain pipe 4 is provided with a multi-ring ring gear 47, and the multi-ring ring gear 47 is located inside the installation sleeve 45. uniformly distributed in the axial direction.

[0055] When it is necessary to install the water pipe on the drain pipe 4, first set the water pipe on the outer wall of the drain pipe 4, and then drive the water pipe to move downward. down ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com