Air volume adjusting plate for plug-in box, and application method thereof

A technology of air volume adjustment and application method, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment construction parts, etc., and can solve problems such as increased use cost and equipment cost, reduced module performance, and increased fan power consumption. Achieve the effects of reducing the cost of the subrack, balancing noise and power consumption, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

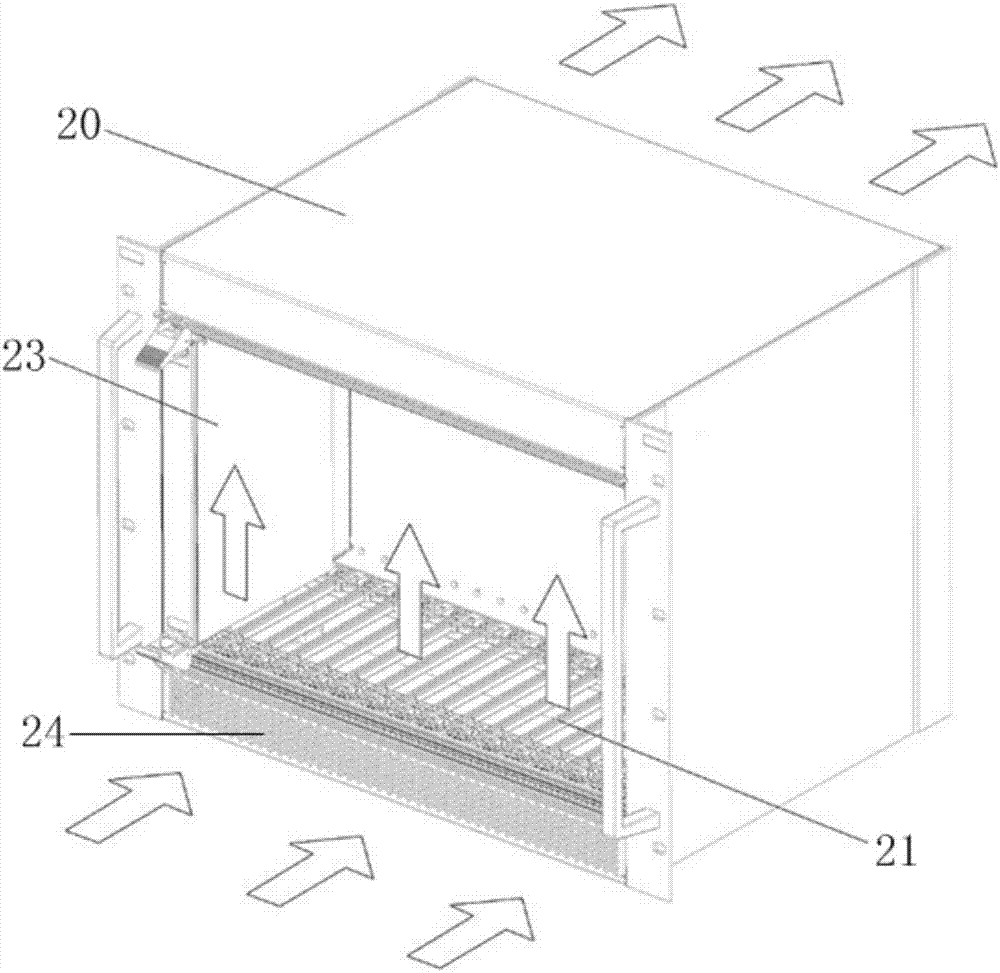

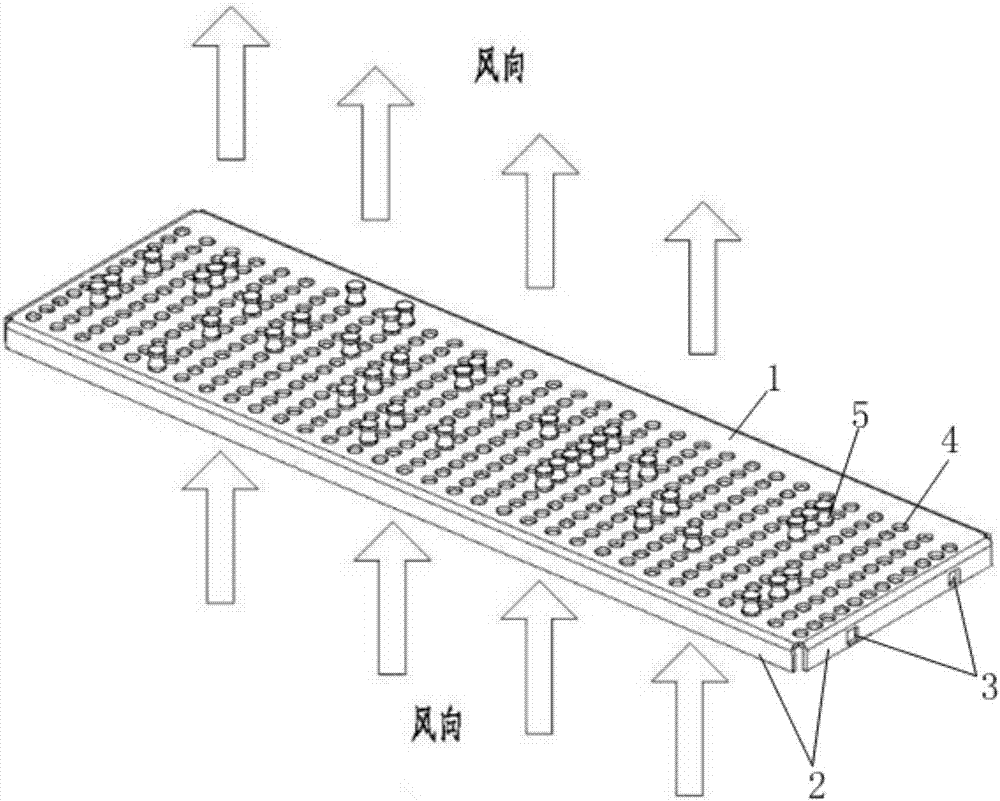

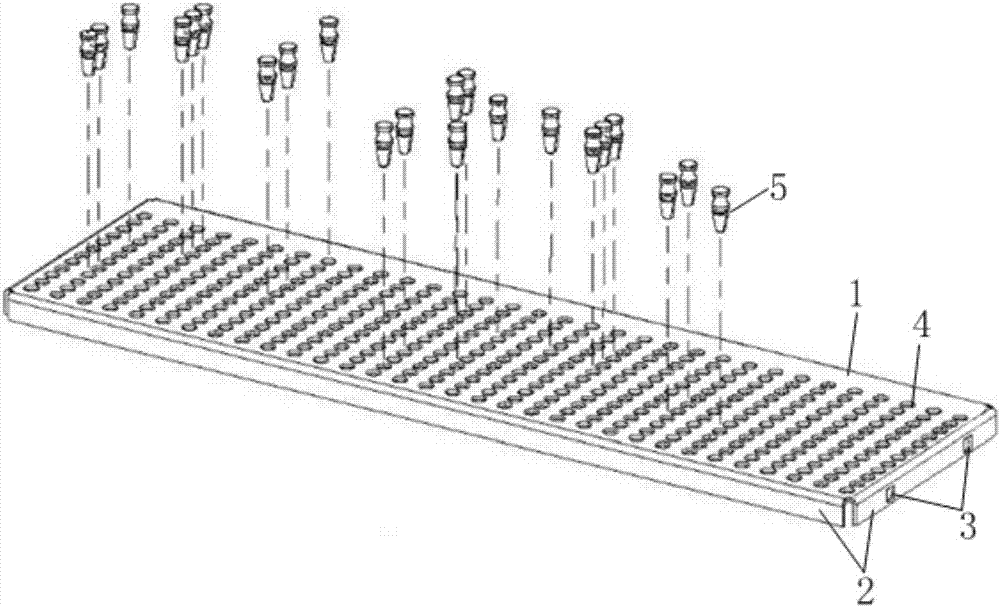

[0038] Such as Figure 2 to Figure 6 As shown, the air volume adjustment plate is mainly used in subracks, and specifically includes a plate body 1 matching the shape of the bottom of the subrack, a connecting part 2 arranged on the side of the panel, and opened on the connecting part for connecting the subracks. port 3, a plurality of ventilation holes 4 opened on the board and arranged regularly, and a plurality of plugs 5 respectively inserted in different ventilation holes for changing the ventilation volume at different positions on the board. In this embodiment, the ventilation holes are regularly arranged in a 12×32 matrix, that is, 12 ventilation holes are arranged in a row, and a total of 32 rows are arranged in parallel. The spacing between the 12 ventilation holes in the row can be relatively close, and the spacing between the ventilation holes in each row matches the gap between the guide rails in the subrack, ensuring that the gap between each guide rail correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com