Conical nut for pipeline joint

A technology for conical nuts and pipe joints, applied in the direction of nuts, pipes/pipe joints/fittings, screws, etc., which can solve the problems affecting the overall sealing performance of the pipeline transportation system, the inability to guarantee the tightness of the connection, and poor fastening performance. , to achieve the effect of increasing connection reliability, ensuring reliability and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

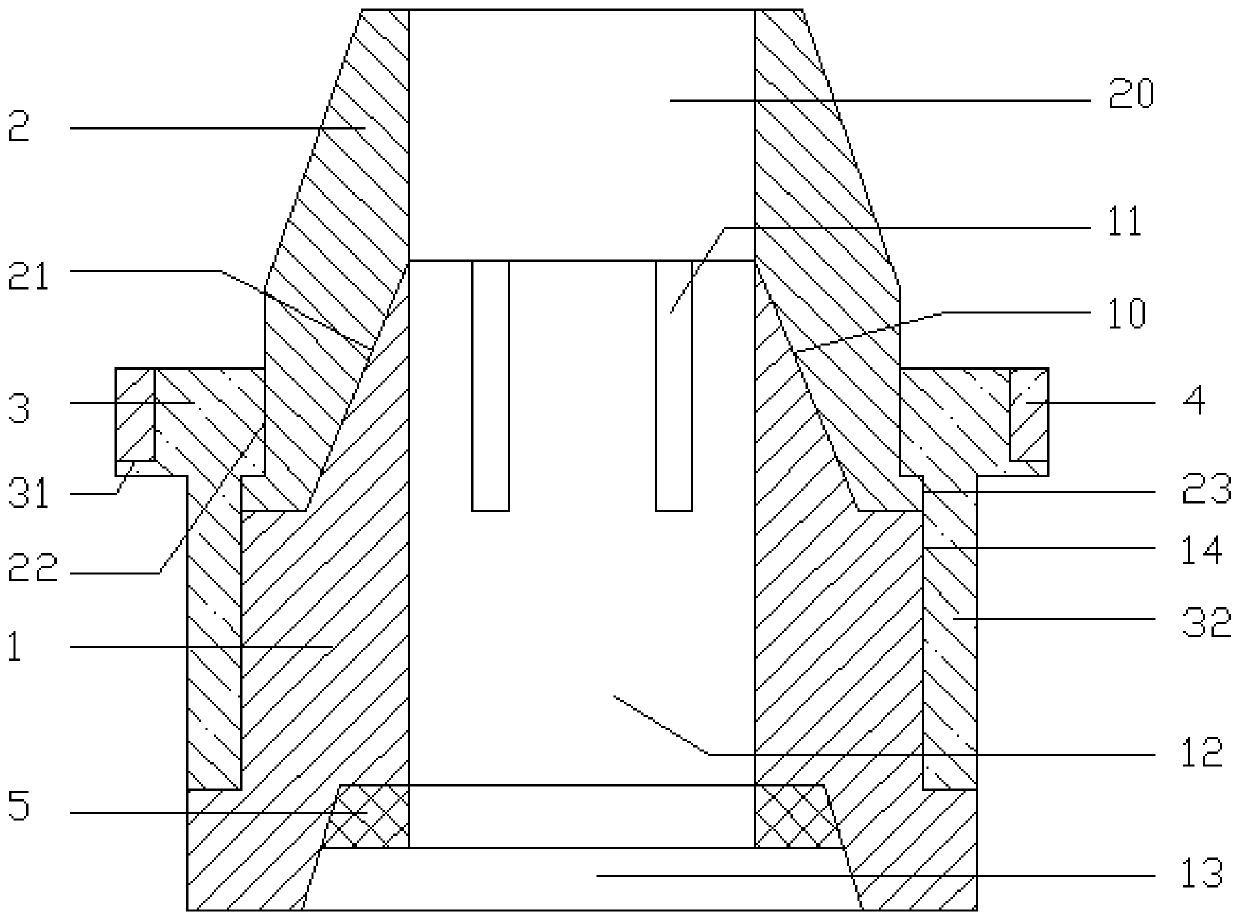

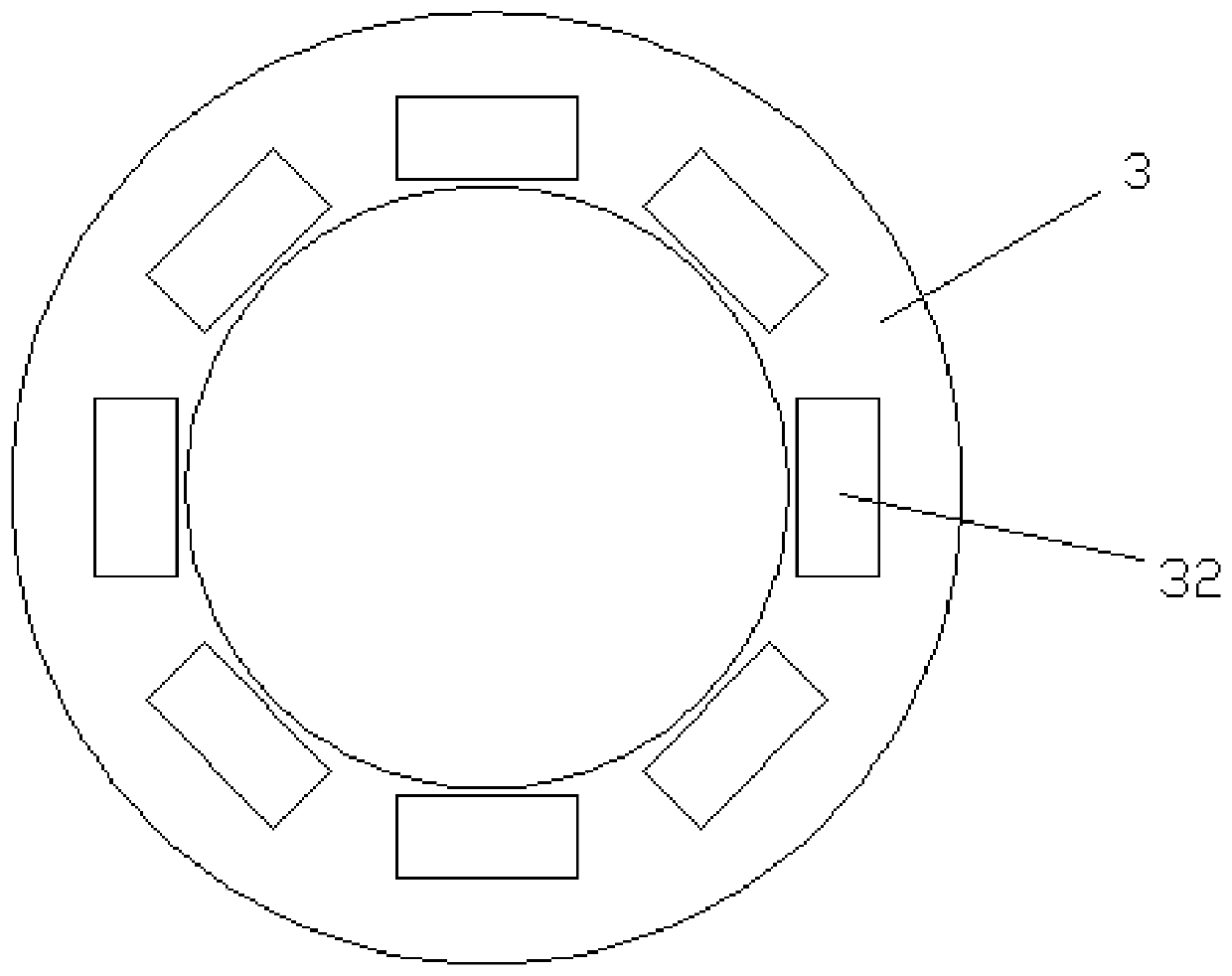

[0015] Referring to the accompanying drawings, the present invention is a tapered nut for pipe joints, including a first nut 1, a second nut 2, an anti-loosening lock sleeve 3 and a lock nut 4, and the first nut 1 also includes a second nut connection end 10. Shrink groove 11, first through hole 12 and threaded through hole 13, the top of the first nut 1 is provided with a second nut connection end 10, and the second nut connection end 10 is provided with an external thread, the The bottom of the second nut 2 is provided with a counterbore 21, and the inside of the counterbore 21 is provided with an internal thread, and the second nut 2 is fixedly installed on the second nut connecting end 10 through the counterbore 21, and the second nut is connected to The end 10 is provided with evenly distributed shrinkage grooves 11, the inside of the first nut 1 is provided with a first through hole 12, the bottom of the first through hole 12 is provided with a threaded through hole 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com