A super high temperature displacement sensor

A displacement sensor, ultra-high temperature technology, applied in instruments, measuring devices, electrical devices, etc., can solve the problems of low accuracy and large sensor zero voltage, improve measurement accuracy, reduce zero voltage, and simplify the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

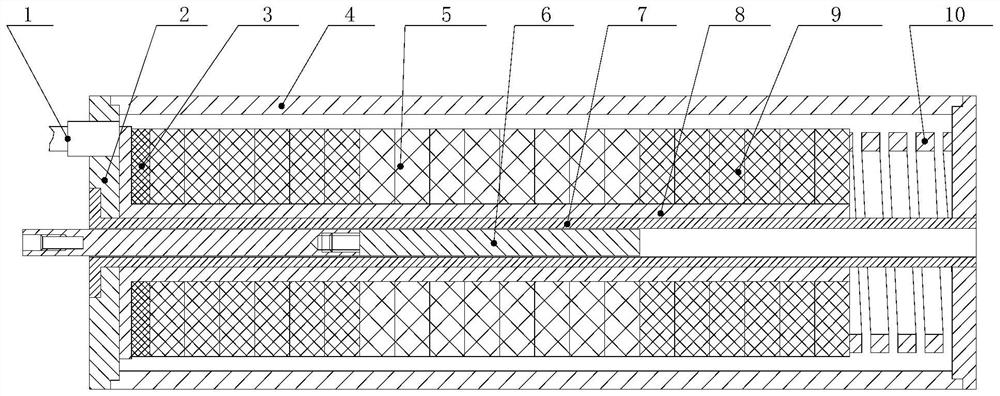

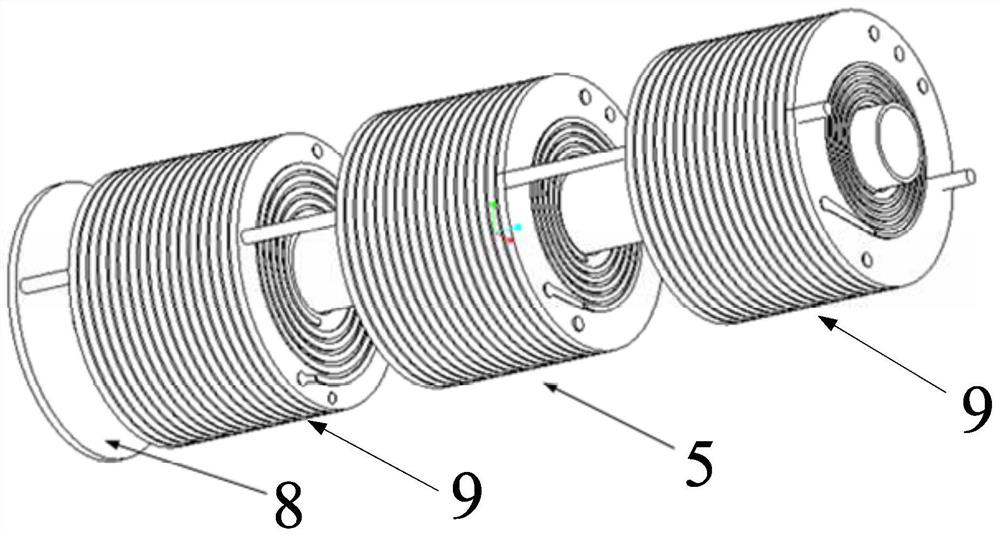

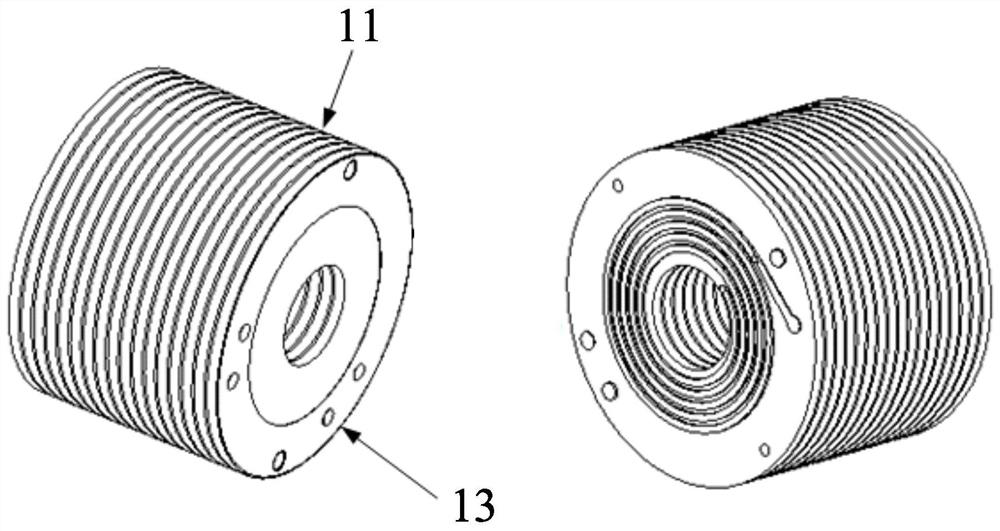

[0020] Specific implementation mode one, the following combination Figure 1 to Figure 6 Describe this embodiment mode, an ultra-high temperature displacement sensor described in this embodiment mode, the displacement sensor includes an end cover 2, a housing 4, an excitation winding 5, an iron core 6, a hollow cylinder 7, a skeleton 8 and two sets of output windings 9;

[0021] The shell 4 is a cylindrical structure, and the two ports of the cylindrical structure are respectively provided with end caps 2; the centers of the two end caps 2 are opened with circular through holes, and the hollow cylinder 7 passes through the two end caps 2 The through hole is fixedly connected with the end cover 2; and the hollow cylinder 7, the end cover 2 and the housing 4 form a sealed cavity;

[0022] The hollow cylinder 7 is inserted with an iron core 6, and the iron core 6 is axially fed displacement inside the hollow cylinder 7;

[0023] The skeleton 8, the excitation winding 5 and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com