Precise adjustment lens frame for large-aperture optical element

A technology for optical components and precise adjustment, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems of increasing the load bearing of optical components, large installation space requirements, and easy interference of optical paths, so as to meet the installation and adjustment requirements and save space , the effect of not interfering with the optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

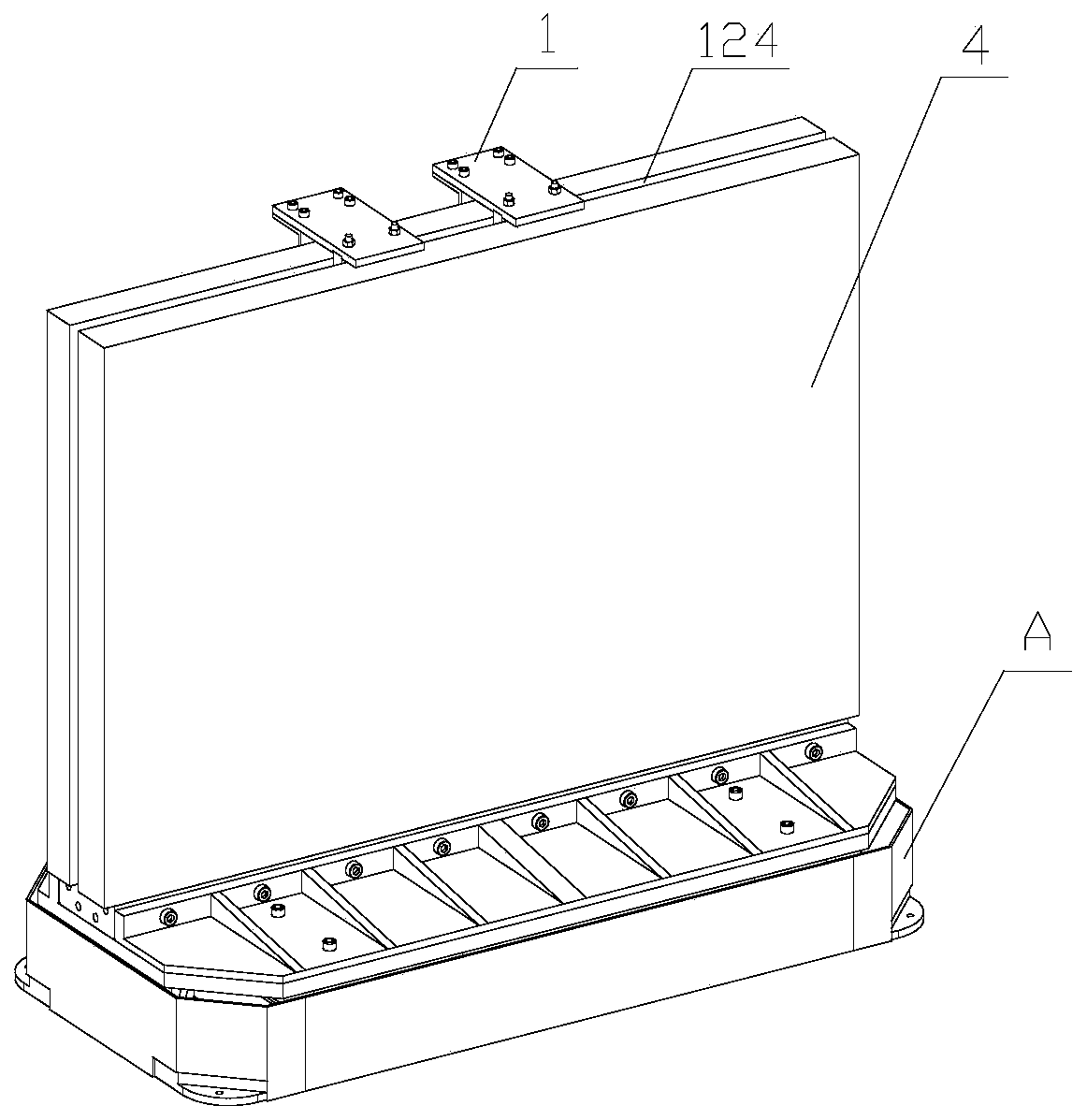

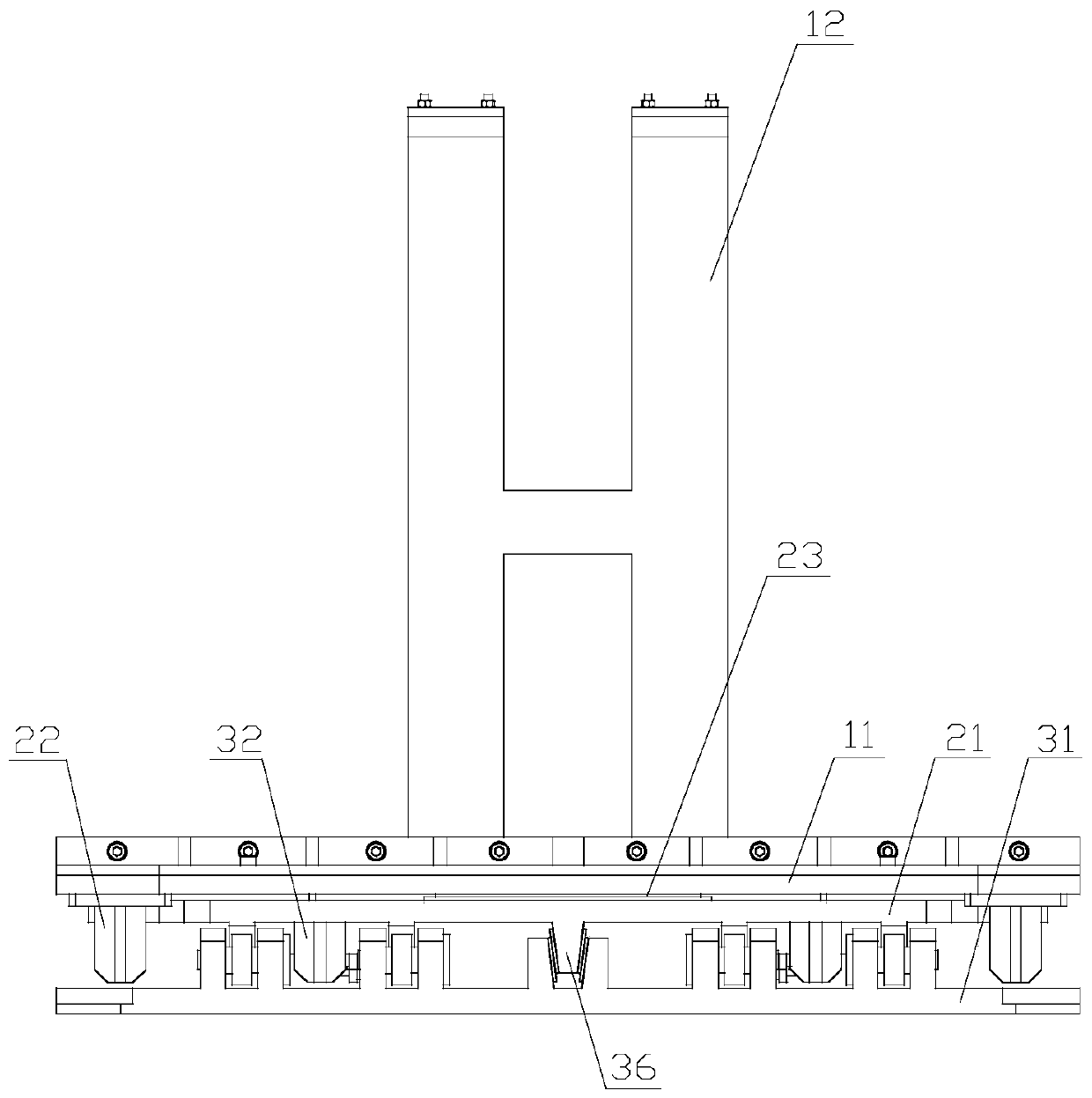

[0058] This embodiment provides a precision adjustment frame for large-diameter optical elements, including a mounting assembly 1, an adjustment mechanism and a platform, and the adjustment mechanism is fixed on the platform. The adjustment mechanism includes a deflection assembly 2 and a pitch assembly 3, the installation assembly 1 includes a first layer 11 and a positioning member 12; the deflection assembly 2 includes a second layer 21 and a deflection drive member 22, and the pitch assembly 3 includes The third layer plate 31 and the tilting driving member 32;

[0059] The first laminate 11, the second laminate 21 and the third laminate 31 are arranged sequentially from top to bottom, and the first laminate 11, the second laminate 21 and the third laminate 31 are rectangular parallelepiped or similar The board structure, and the three boards are arranged parallel to each other;

[0060] The positioning part 12 is arranged on the first laminate 11 and is located above the...

Embodiment 2

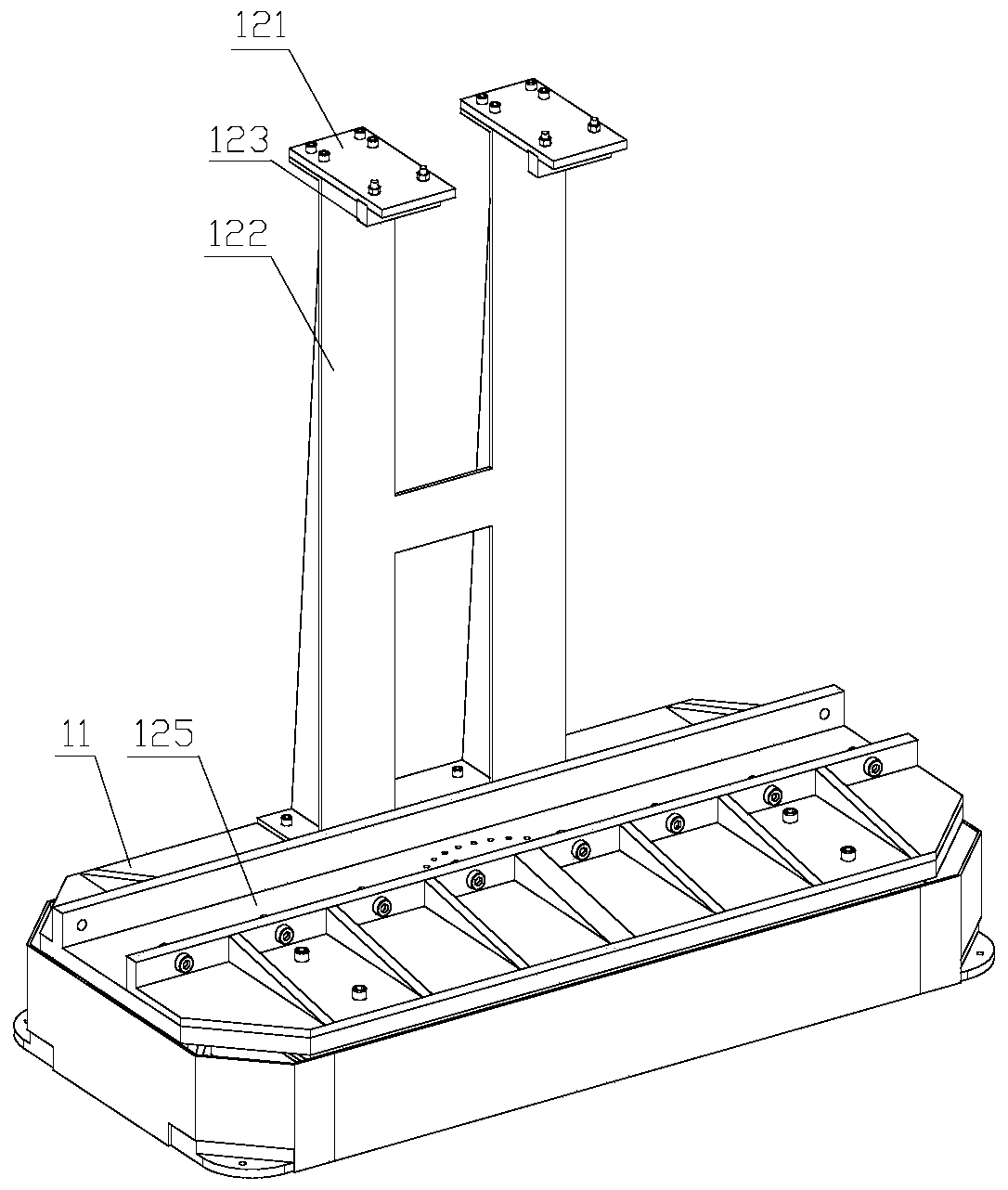

[0064] Further improvement on the basis of Embodiment 1, the positioning member 12 includes a mounting base plate 121 and a ribbed steel plate 122, the mounting base plate 121 adopts a steel plate structure; one end of the mounting base plate 121 is connected to the first layer plate 11 through the ribbed steel plate 122, The axial ends of the ribbed steel plate 122 are respectively detachably connected to the mounting base plate 121 and the first layer plate 11 through bolts; the other end of the mounting base plate 121 is used to clamp the optical element 4, and the upper and lower ends of the optical element 4 are clamped on the mounting base plate 121 between the lower surface and the upper surface of the first laminate 11 . The positioning part 12 also includes a polytetrafluoroethylene insert 123, and the polytetrafluoroethylene insert 123 is fixed on the other end of the mounting substrate 121 by bolts; the top of the optical element 4 is provided with a positioning groo...

Embodiment 3

[0066] Further improvement on the basis of Embodiment 2, both the yaw driving member 22 and the pitching driving member 32 adopt a linear motion drive, and the linear motion drive includes a servo motor assembly 51, a coupling 52, a nut 53, and a screw rod 54 , nut seat 55, linear guide rail 56 and base 57; the servo motor assembly 51 includes a brushless servo motor and a zero-backlash reducer, and the nut 53 and the screw mandrel 54 respectively adopt an anti-backlash screw rod and an anti-backlash nut; the servo motor assembly 51 is After the reducer decelerates, the screw 54 is driven to rotate through the coupling 52, and the nut 53 drives the nut seat 55 to move linearly on the linear guide rail 56 under the drive of the screw 54; On the lower plate surface of the lower plate, the pitch drive assembly 32 is fixed on the upper plate of the third layer plate 31 through the base 57;

[0067] The free end of the nut 53 is hingedly connected with the first layer 11 or the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com