Hardened soil breaking and thinning device for garden planting

A soil clod and compaction technology, which is applied in the field of compacted soil clod crushing and refining devices for garden planting, can solve the problems that the soil or soil clods cannot be fully refined, and the soil crushing range is limited, and achieve a high degree of refinement and a large crushing range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

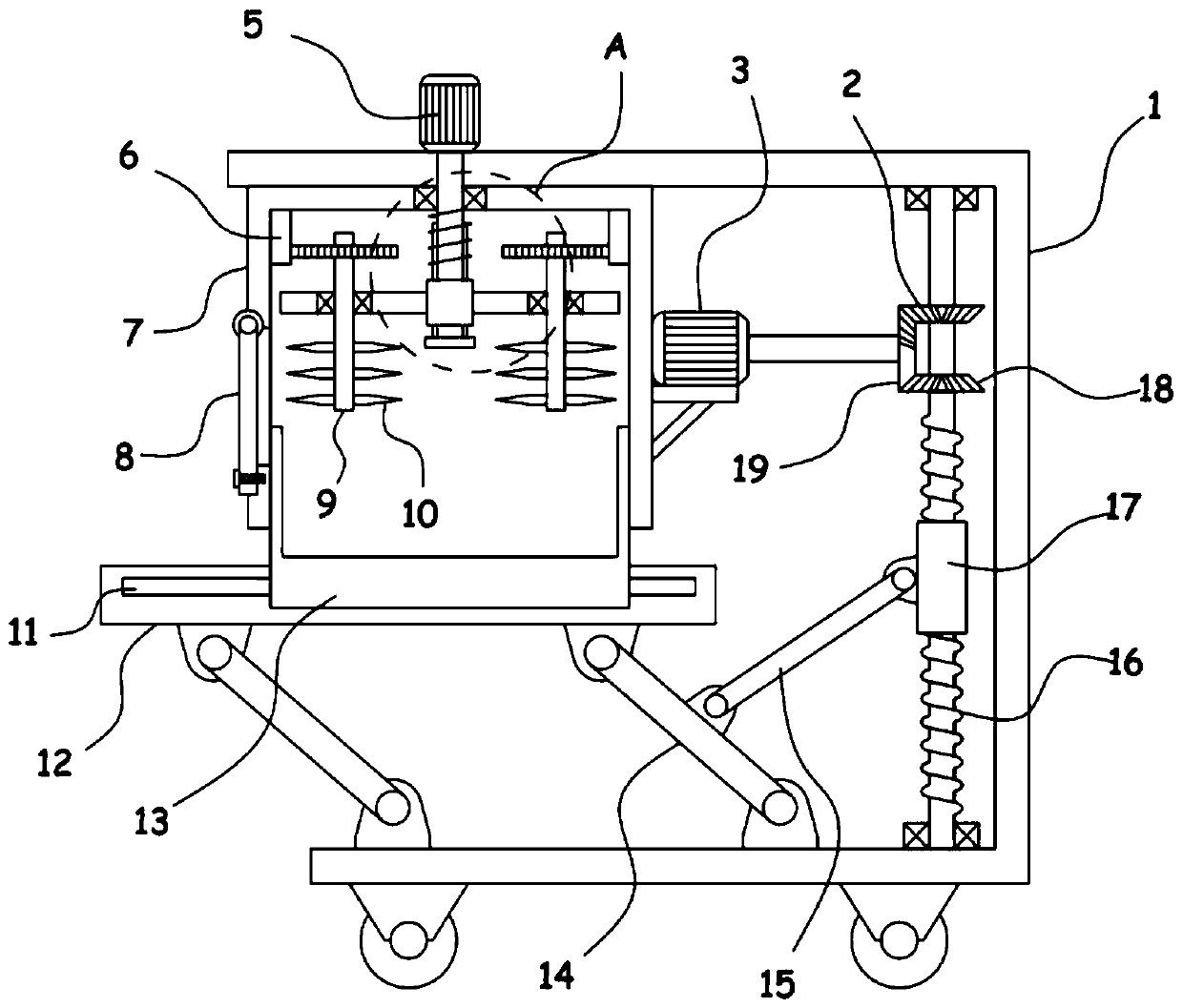

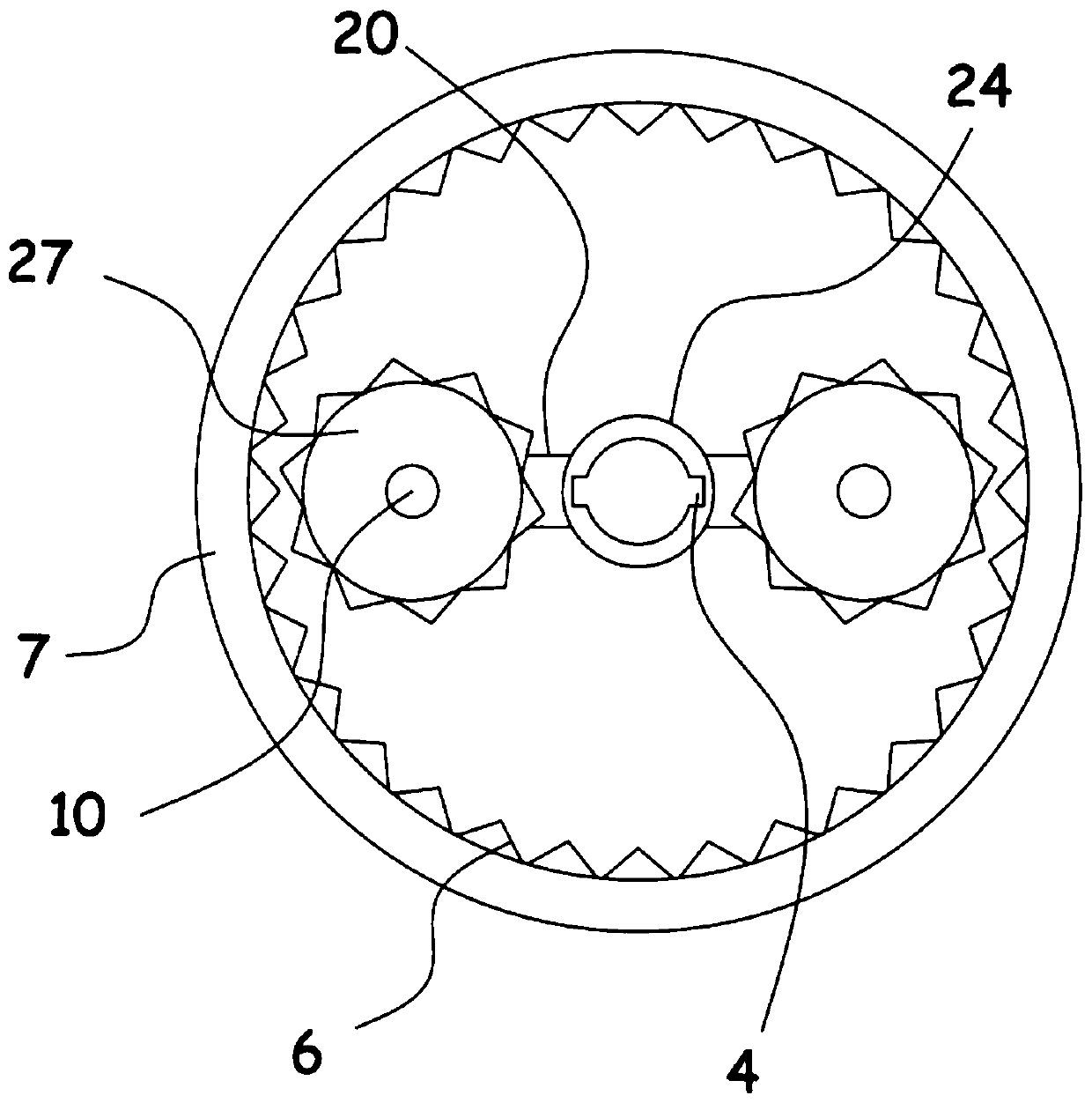

[0024] see Figure 1-5 , a crushing and refining device for compacted soil blocks for garden planting, comprising a mobile frame 1, a coaming plate 7 is fixedly installed on the top of the mobile frame 1, and a feeding cover plate 8 is provided on the side wall of the coaming plate 7, and the bottom of the coaming plate 7 The lifting plate 12 is driven and connected by the lifting mechanism. The lifting plate 12 is equipped with a crushing groove 13 that slides and extends into the coaming 7. The coaming 7 is provided with a crushing mechanism driven by a servo motor II5. The crushing mechanism includes a turret 20, which rotates The frame 20 is rotatably equipped with a crushing assembly for crushing soil clods.

[0025] The device can put soil clods into the coaming 7 by opening the feeding cover plate 8, and the soil clods fall into the inside of the crushing tank 13, and then the crushing components are driven by the provided crushing mechanism to rotate and crush the soil...

Embodiment 2

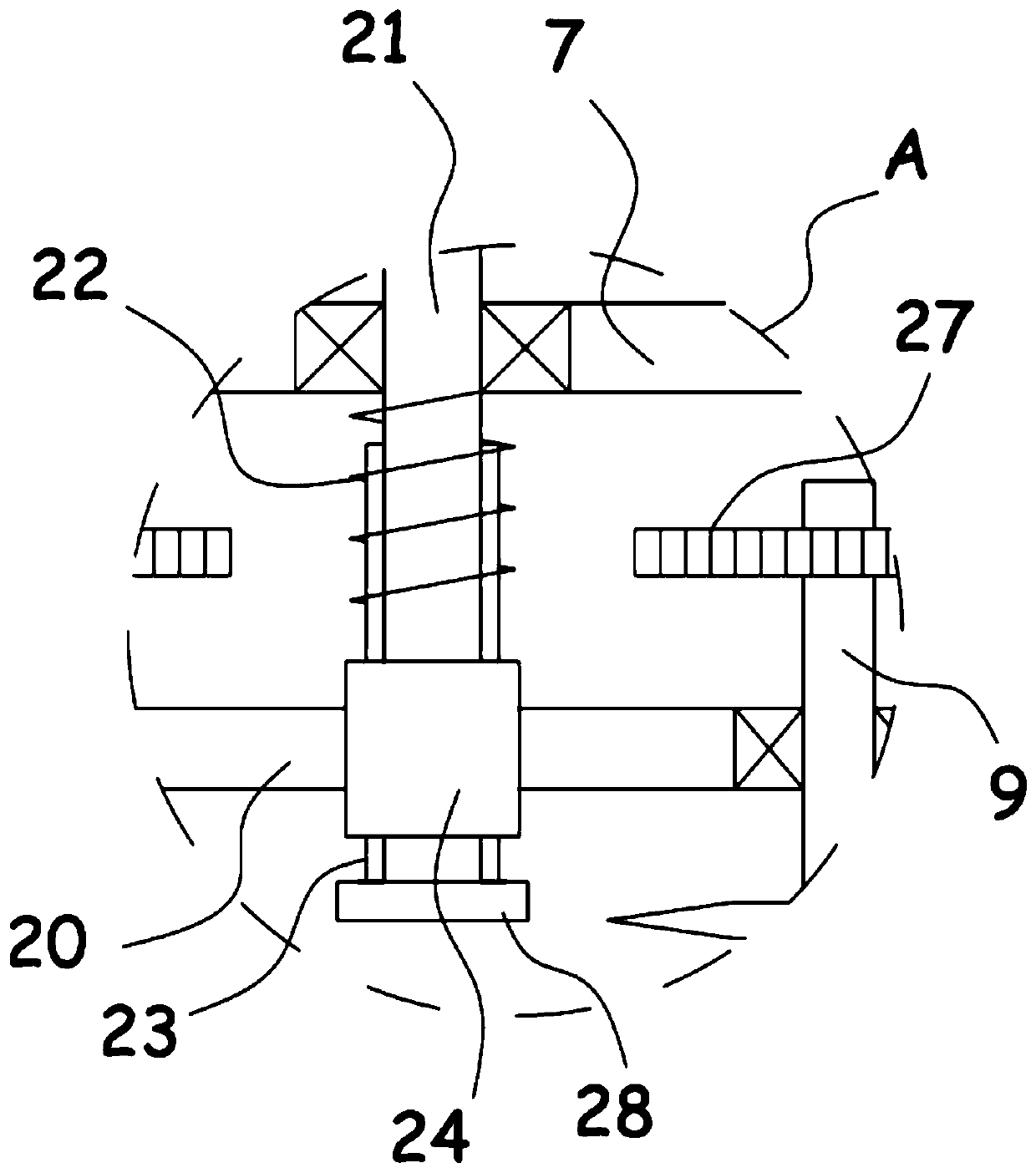

[0030] In order to make the soil clods at different positions in the vertical direction inside the crushing groove 13 all be crushed and refined, on the basis of Embodiment 1, in addition, a clamping groove 4 is axially provided on the inner side wall of the transmission sleeve 24, and the clamping groove 4 is In the groove 4, there is a clip 23 fixed on the side wall of the drive shaft 21, which is slidably engaged. The drive shaft 21 is sleeved with a spring ring 22 with two ends abutting against the shroud 7 and the transmission sleeve 24 respectively, and the lower end of the drive shaft 21 is fixed. There is a bottom plate 28 .

[0031] The lifting mechanism of the device can drive the crushing tank 13 on it through the lifting plate 12 to adjust the height of the upper and lower sides along the coaming plate 7, so that the crushing blade 10 can extend downward relative to the crushing tank 13, and then realize different crushing in the crushing tank 13. Deep soil clods a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com