Green and environment-friendly packaging bag and preparation method thereof

A green and environmentally friendly packaging bag technology, applied in the field of plastic film, can solve the problems of not easy to be degraded by natural microorganisms, plastic bags cannot be degraded quickly, and slowly degraded, and achieve the effects of reducing land load, stable performance, and enhanced crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

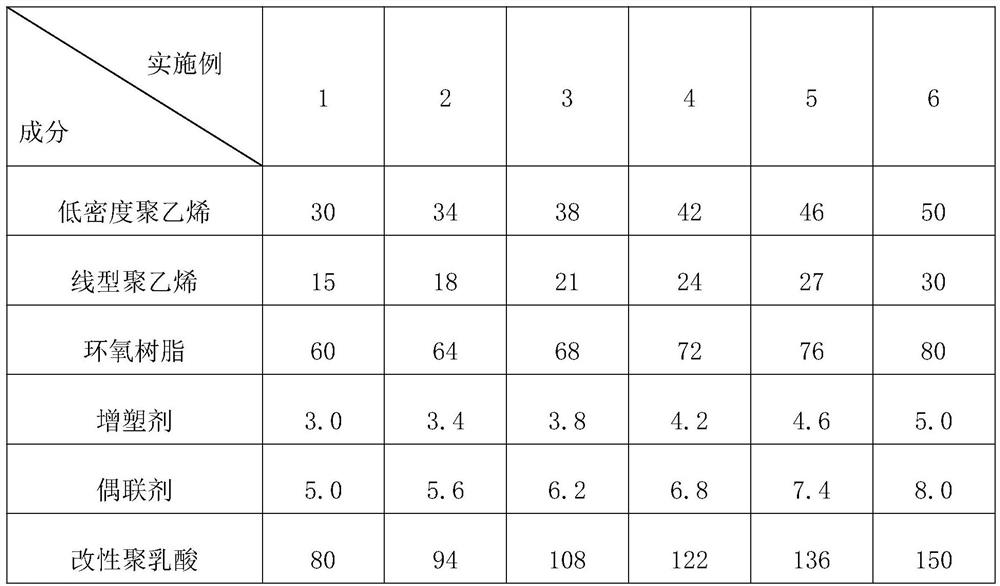

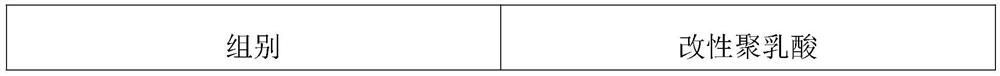

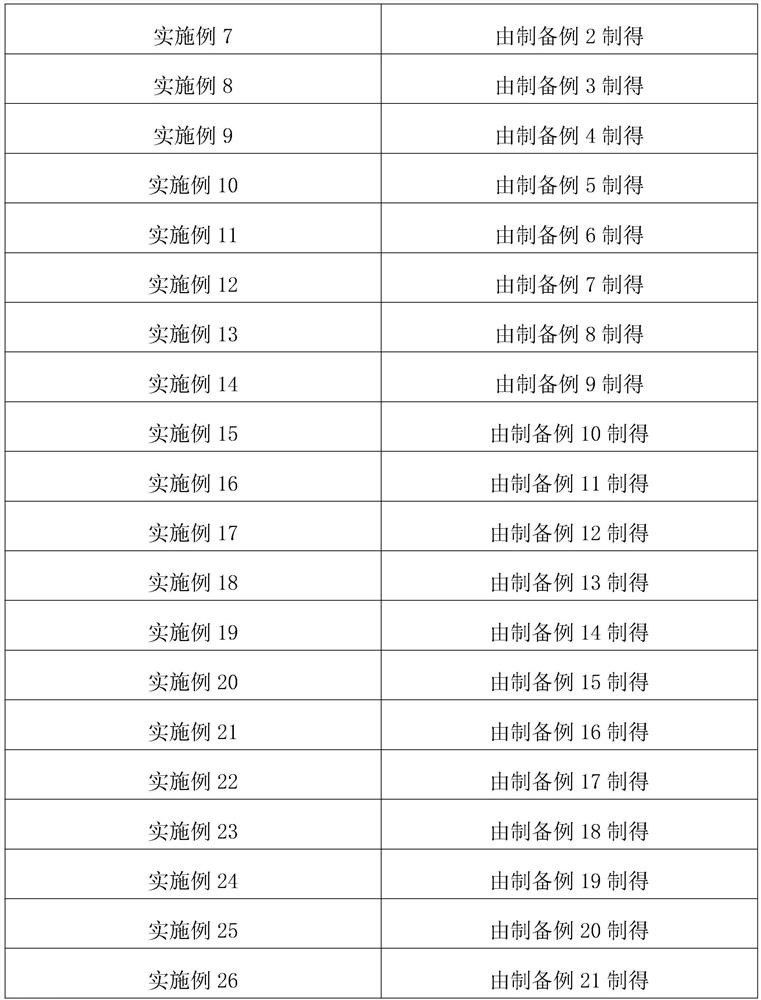

Examples

preparation example 1

[0059] A kind of modified polylactic acid, its preparation steps are as follows:

[0060] a. Pretreatment: Heat the modified solution to 60°C under the acidic condition of pH 5.5, and stir at a speed of 500r / min for 30min;

[0061] The modified liquid is composed of mixed colloid and plant fiber filler in a weight ratio of 1:0.2;

[0062] The plant fiber filler is straw fiber powder;

[0063] The mixed colloid is composed of starch, hyperbranched polyacrylate and toluene diphenyl phosphate in a weight ratio of 1:0.2:0.05;

[0064] b. Modification treatment: Polylactic acid and the pretreated modification liquid in a are composed at a weight ratio of 1:0.5, heated to 180°C under negative pressure and vacuum, and stirred at a speed of 200r / min for 20min. Modified polylactic acid can be obtained.

preparation example 2

[0066] A modified polylactic acid, the difference from Preparation Example 1 is that in a, the modified solution is heated to 70°C under acidic conditions with a pH of 6.0, and stirred at a speed of 650r / min for 45min.

preparation example 3

[0068] A modified polylactic acid, the difference from Preparation Example 1 is that in a, the modified solution is heated to 80°C under acidic conditions with a pH of 6.5, and stirred at a speed of 800r / min for 60min;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com