Sorting vehicle, sorting main engine adopting sorting vehicle and halved belt sorting machine

A main engine and vehicle body technology, applied in the field of machinery, can solve the problems of life and work disturbance, loud noise, and difficult installation, and achieve the effects of no maintenance, avoidance of instantaneous power, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding and should be considered as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted from the following description for clarity and conciseness.

[0034] According to an aspect of the embodiments of the present invention, a sorting vehicle is provided.

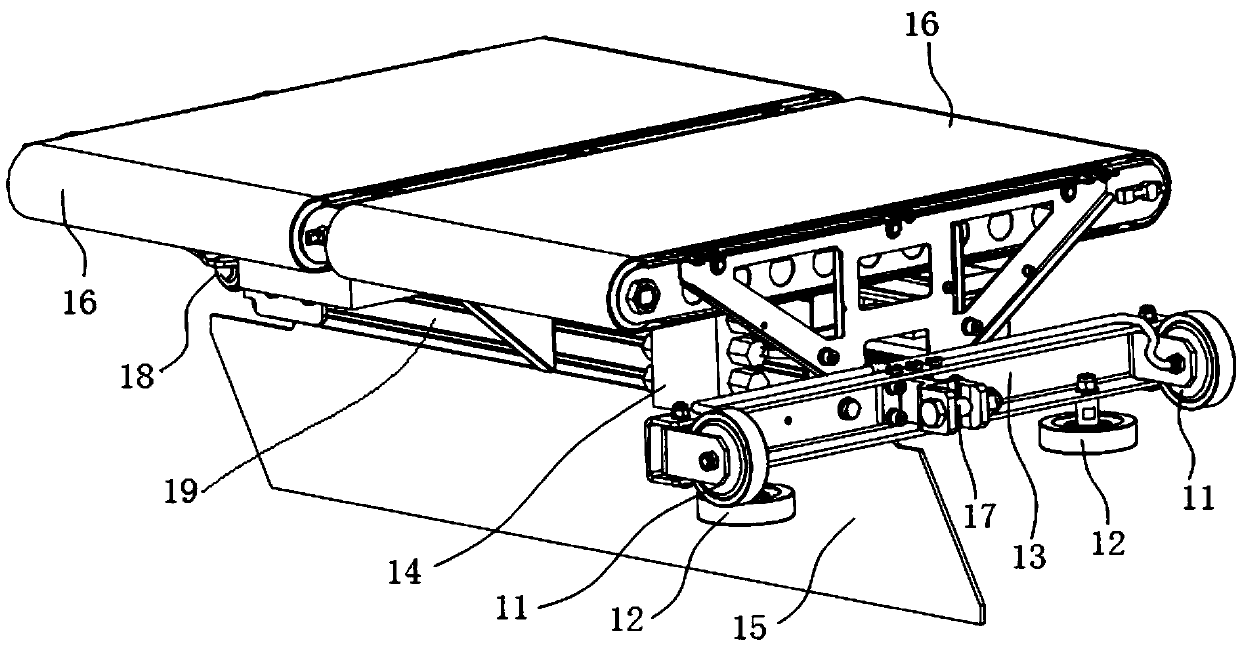

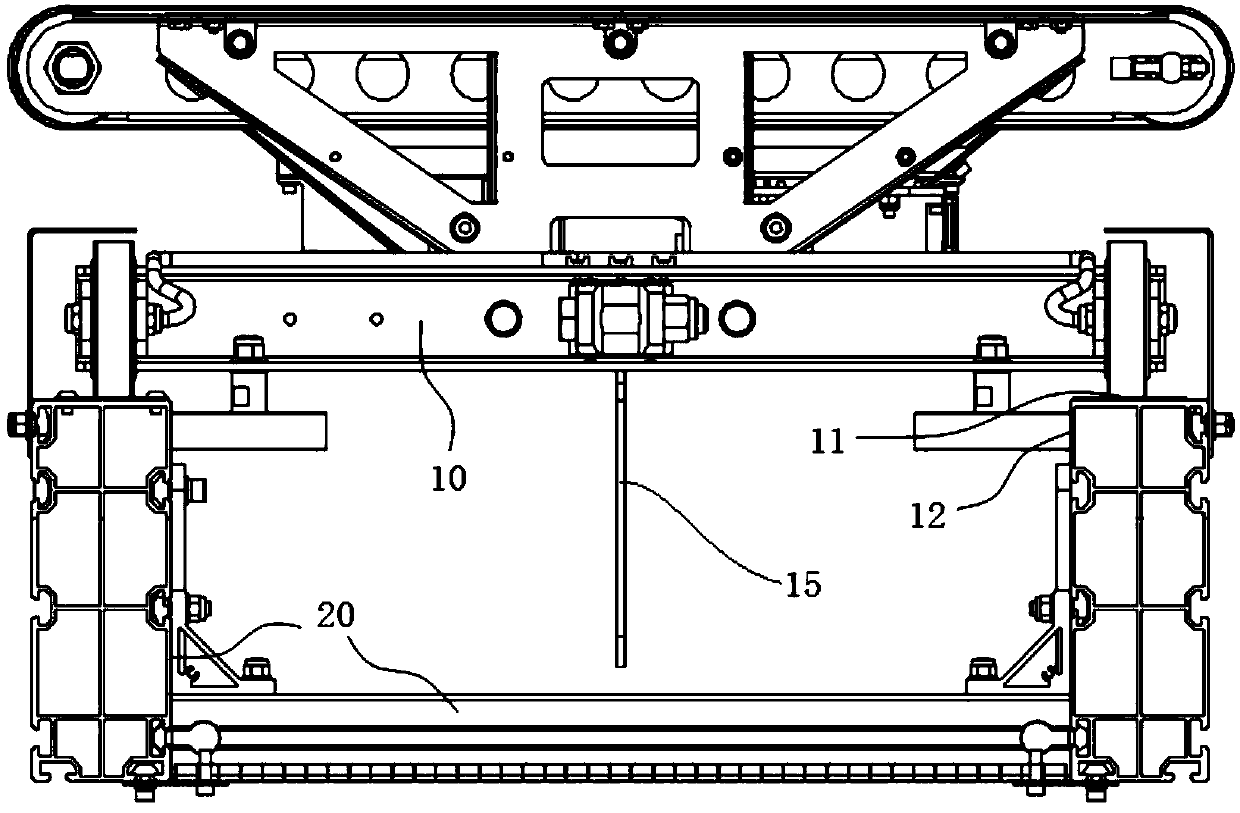

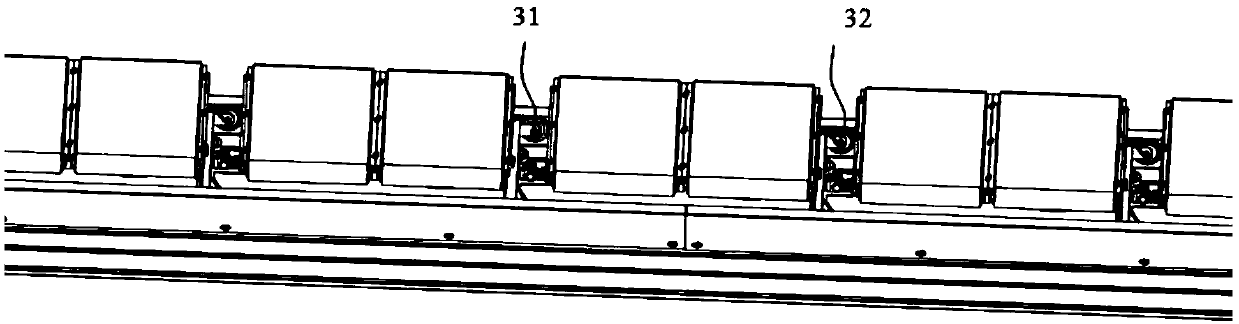

[0035] figure 1 It is a schematic diagram of the main components of a sorting vehicle according to some embodiments of the present invention. like figure 1 As shown, the sorting vehicle according to the embodiment of the present invention includes N sorting units; the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap