Bottled drug anti-falling type check weighing waste product rejection device

An anti-dumping and bottle-filling technology, applied in sorting and other directions, can solve problems such as medicine bottle dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

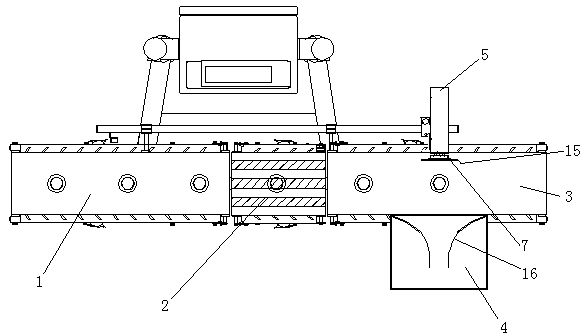

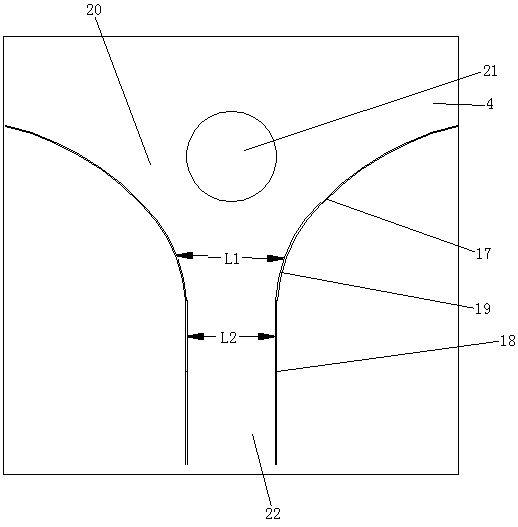

[0019] Embodiment one, see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a bottled medicine anti-dumping type checking weighing and rejecting device, comprising a feeding conveyor belt 1, an online weighing platform 2 and a waste rejecting conveyor belt 3 arranged sequentially from back to front along the conveying direction of bottled medicine. One side of rejecting waste conveyer belt is provided with receiving platform 4. The other side of the scrap conveyor belt is provided with a push cylinder 5 that expands and contracts towards the receiving platform. Pushing material cylinder 5 is a double-rod cylinder. The push-pull cylinder and receiving platform are distributed along the conveying direction perpendicular to the waste conveyor belt. A push plate 7 is provided on the piston rod 6 of the material pushing cylinder. Also connected with blocking mechanism 8 on the push plate.

[0020] The front end of the push plate along the conveying direction of t...

Embodiment 2

[0024] Embodiment two, the difference with embodiment one is:

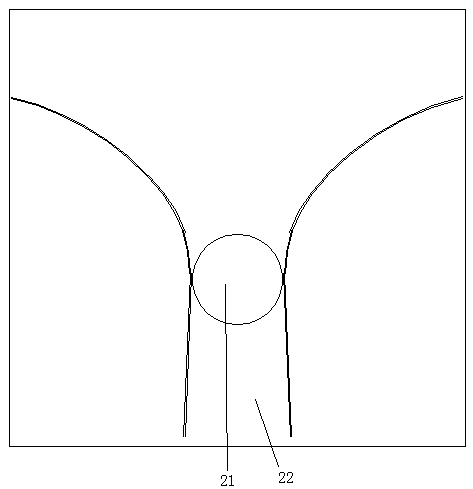

[0025] see Figure 6 and Figure 7 , the rear end of the push plate along the conveying direction of the waste conveyor belt is provided with a rear wall 25 bent toward the direction of the receiving platform. The front baffle is provided with a straight section 26 of the front edge portion perpendicular to the conveying direction of the waste conveyor belt. The rear baffle is provided with a rear wall straight section 27 perpendicular to the conveying direction of the waste conveyor belt. When the bottled medicine 21 abuts against the baffle plate, the vertical plane L6 passing through the center line of the bottled medicine and parallel to the conveying direction of the waste conveyor belt intersects the straight section of the front side wall and the straight section of the back side wall ; When the bottled medicine is dumped backward along the conveying direction of the waste conveyor belt and is simultaneo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com