Structure for improving transverse rigidity of large-span cable-stayed bridge

A lateral stiffness, cable-stayed bridge technology, applied in the field of cable-stayed bridges, can solve the problems of large span, narrow bridge deck and low lateral stiffness of long-span railway cable-stayed bridges, so as to improve lateral stiffness, reduce lateral deformation, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

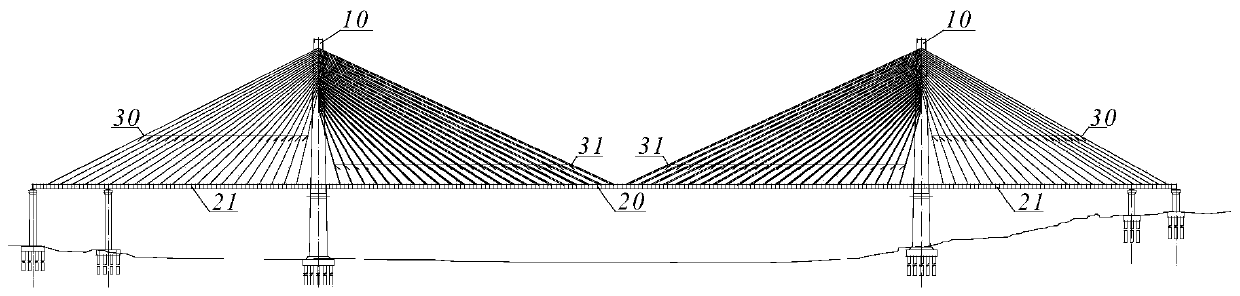

[0018] refer to figure 1 with figure 2 , a kind of structure that improves the transverse rigidity of long-span cable-stayed bridge of the present invention, cable-stayed cable comprises the side-span cable-stayed cable 30 that two ends are respectively anchored on bridge tower 10, side-span girder 21, and two ends are respectively anchored on bridge The mid-span stay cables 31 on the tower 10 and the mid-span girder 20, the mid-span stay cables 31 are composed of paired left stay cables 31a and right side stay cables 31b, and the bridge tower 10 includes a left tower column 11 and right pylon 12. The upper anchor point of the left stay cable 31 a is arranged on the left tower column 11 , and the lower anchor point is arranged on the right side of the mid-span main beam 20 . The upper anchor point of the right stay cable 31 b is arranged on the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com