Self-adaptive forklift potential energy recycling system according to load capacity and control method

A potential energy recovery and control method technology, which is applied in fluid pressure actuation system testing, lifting devices, fluid pressure actuation devices, etc., can solve the problem that the degree of energy recovery of the accumulator cannot be accurately controlled in real time, and the loss of hydraulic oil cannot be replenished in time , energy waste and other issues, to achieve the effect of high specific power, high cycle times and long-lasting energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings. It should be noted that the specific embodiments are only detailed descriptions of the present invention and should not be regarded as limitations of the present invention.

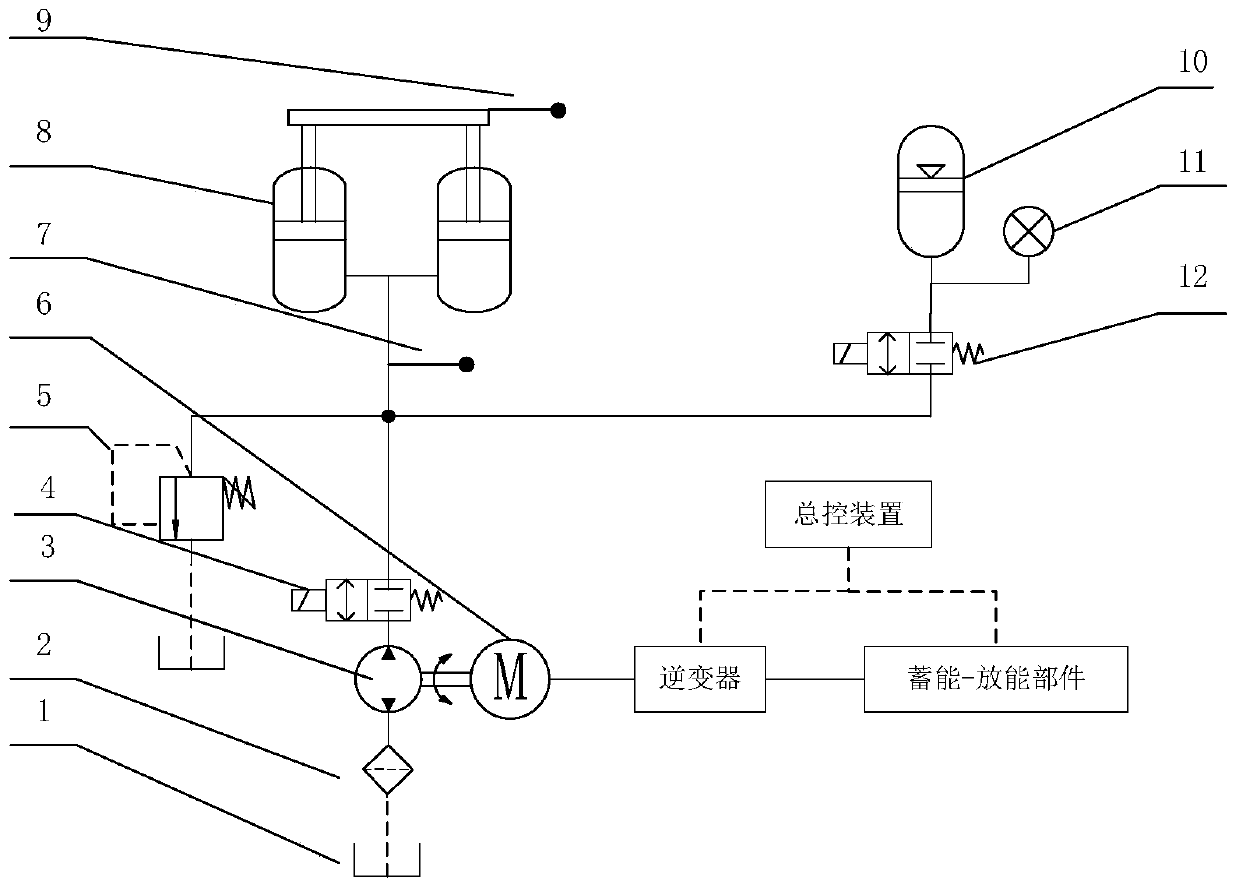

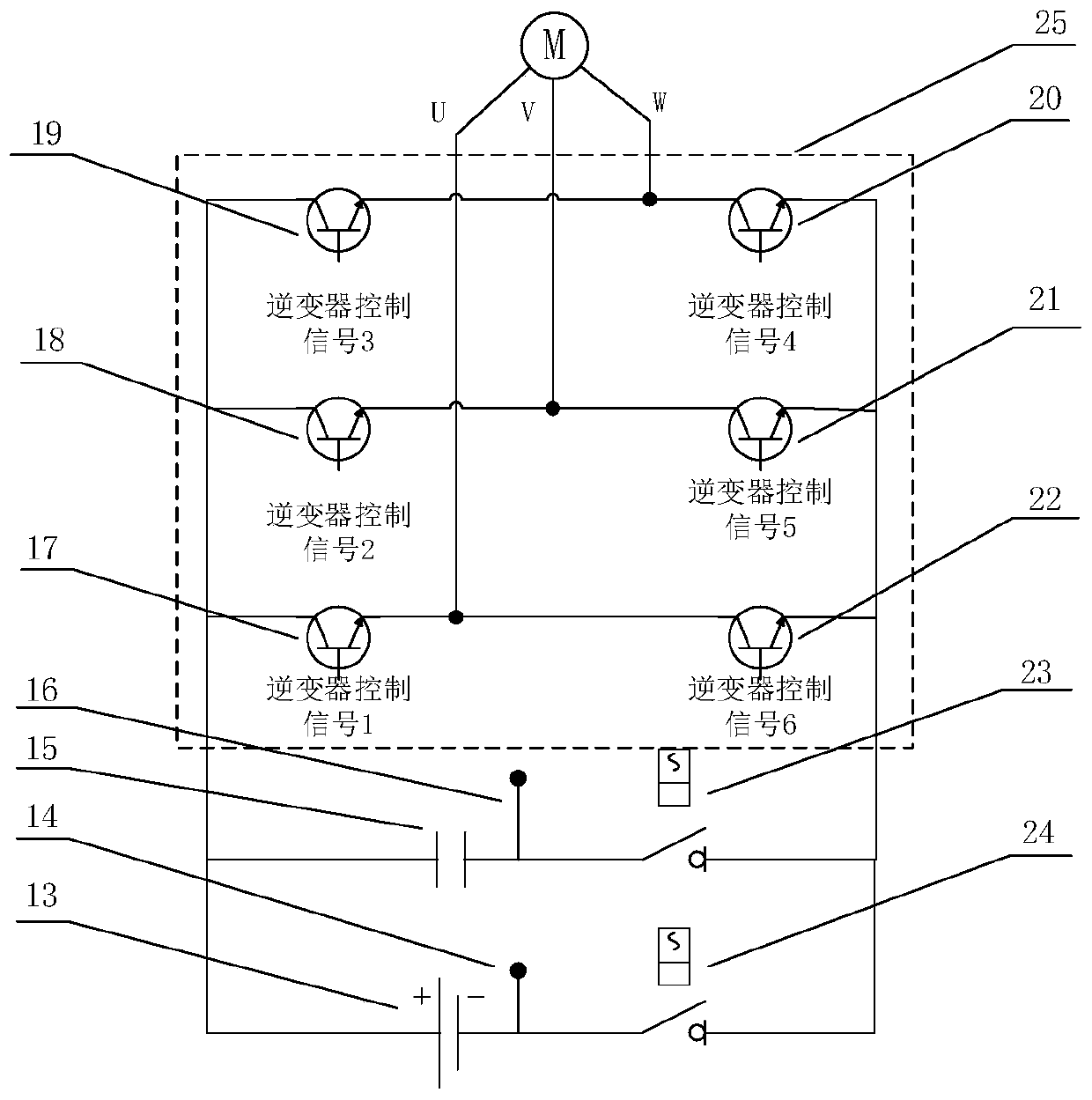

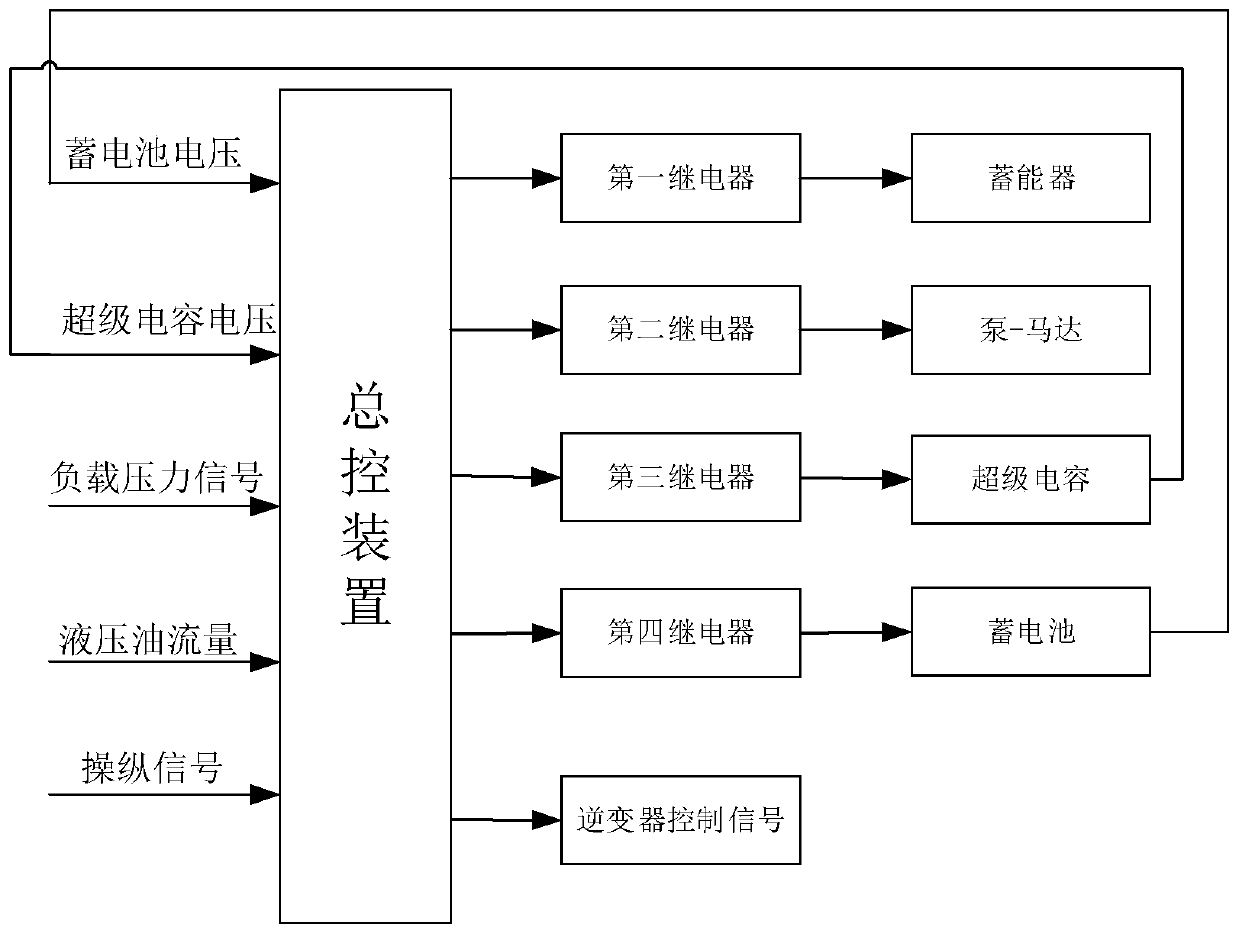

[0033] A forklift potential energy recovery system self-adapting according to the load weight of the present invention, such as figure 1 As shown, it includes a hydraulic oil circuit system composed of a lift cylinder 8, a pump-motor 3 and an oil tank 1, and also includes an accumulator 10, a second electromagnetic proportional throttle valve 12, a first electromagnetic proportional throttle valve 4, a pressure Sensor 9, flow sensor 7, double-acting motor 6, inverter 25, energy storage-discharge components and general control device.

[0034] As a preferred way, the lifting cylinder 8 is connected to the fork for lifting heavy objects, and a pressure sensor 9 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com