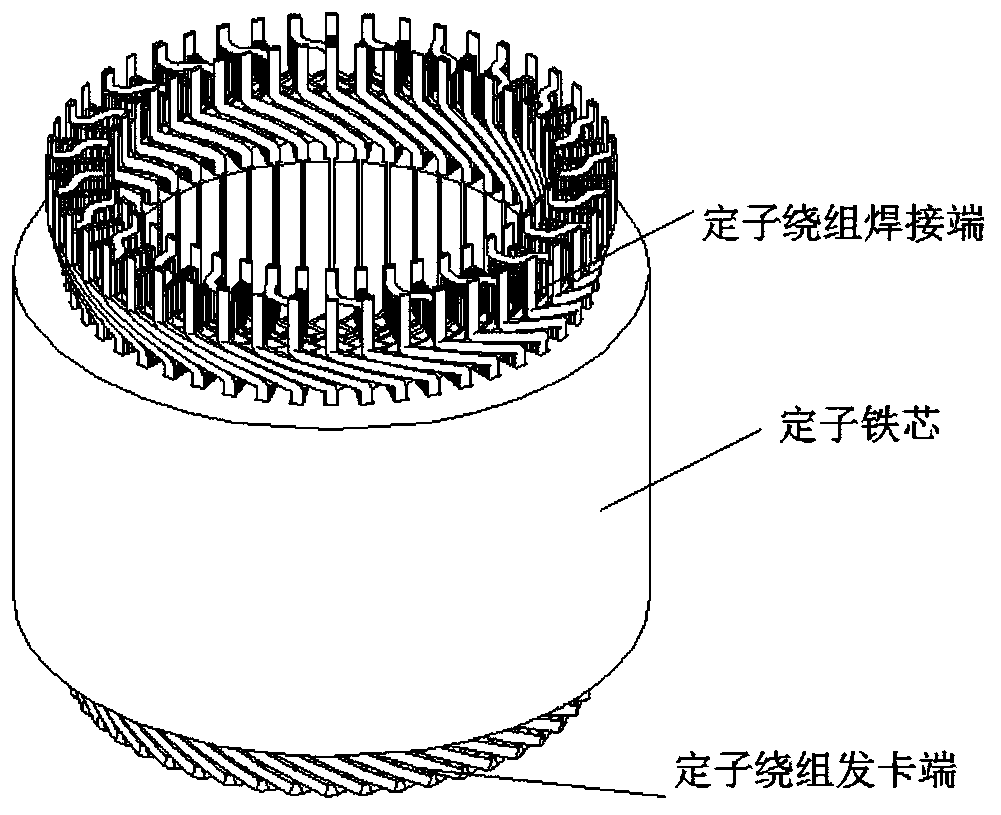

Stator of flat wire motor

A motor stator and flat wire technology, applied in the field of new energy motors, can solve the problems of increasing the difficulty of winding manufacturing process, reducing the full rate of copper slots, and large size, so as to reduce the influence of skin effect, simplify the process, and reduce the size of conductors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

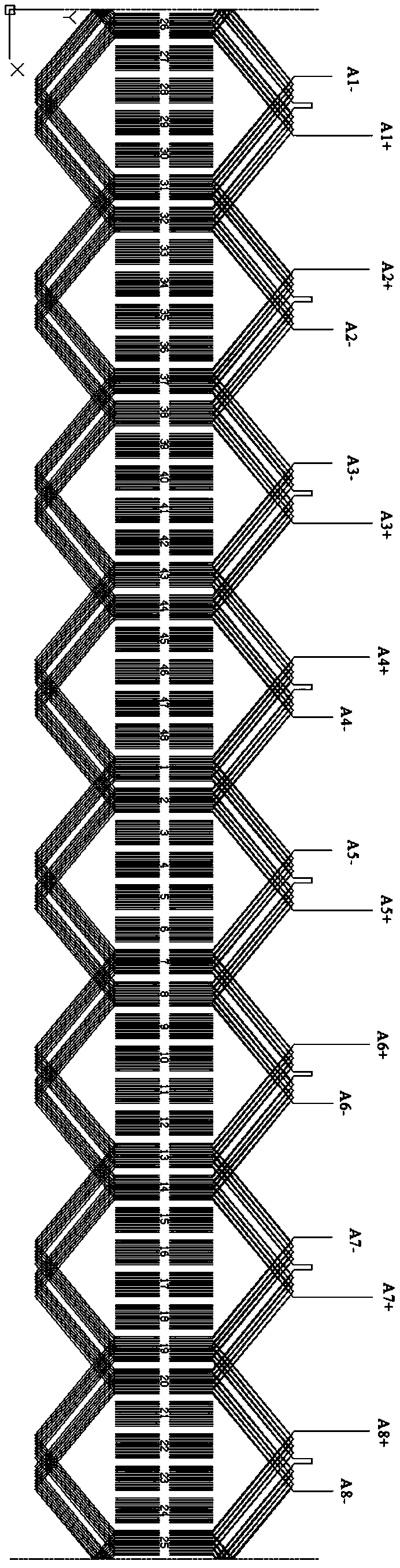

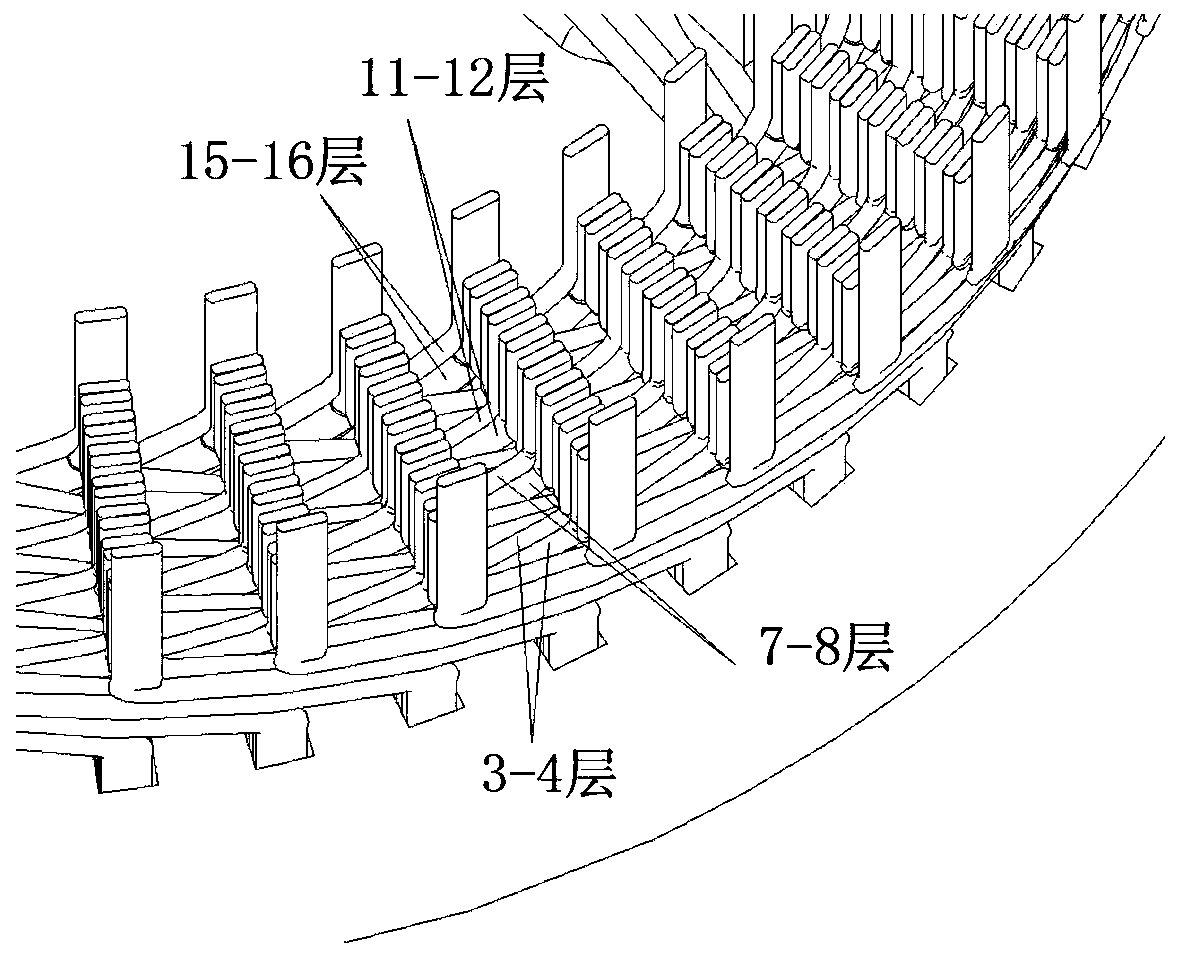

[0024] The hairpin coil is embedded and installed on the stator core, and the hairpin coil is embedded in the stator slot through the embedding part. Make sure that 16 layers of conductors are formed in each stator slot, taking the stator slot as a unit, these 16 layers of conductors can include: the lead-out end of the first layer, the lead-out end of the sixteenth layer, the welding ends of the second layer to the fifteenth layer .

[0025] The coil repeating unit includes a set of two hairpin coils, and the two hairpin coils are composed of overlapping bodies and opposite bending directions. Wherein, the two hairpin coils have four welding parts, and the welding parts of the second layer to the fifteenth layer of all coil repeating units are paired in pairs along the radial direction, so as to realize winding end welding.

[0026] Therefore, welding rules and bending rules are formed after the three-phase coils are embedded and wound.

[0027] The welding rule is the 2nd ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com