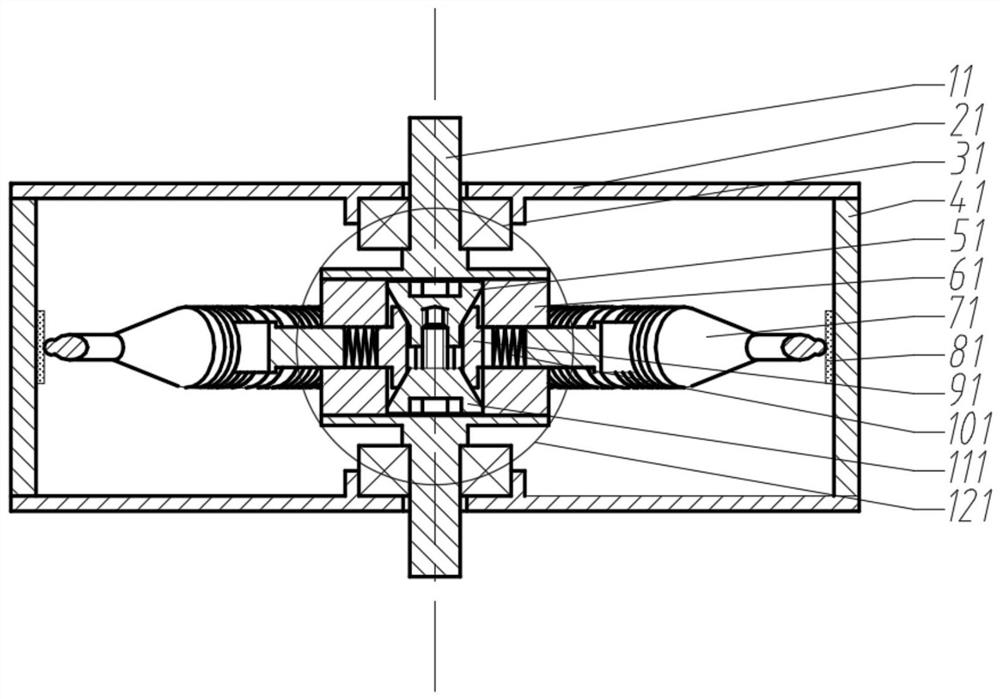

A Multistage Parallel Dual Output Shaft Rotating Ultrasonic Motor

An ultrasonic motor, dual output shaft technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of small radial size, small output torque, lever arm short and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

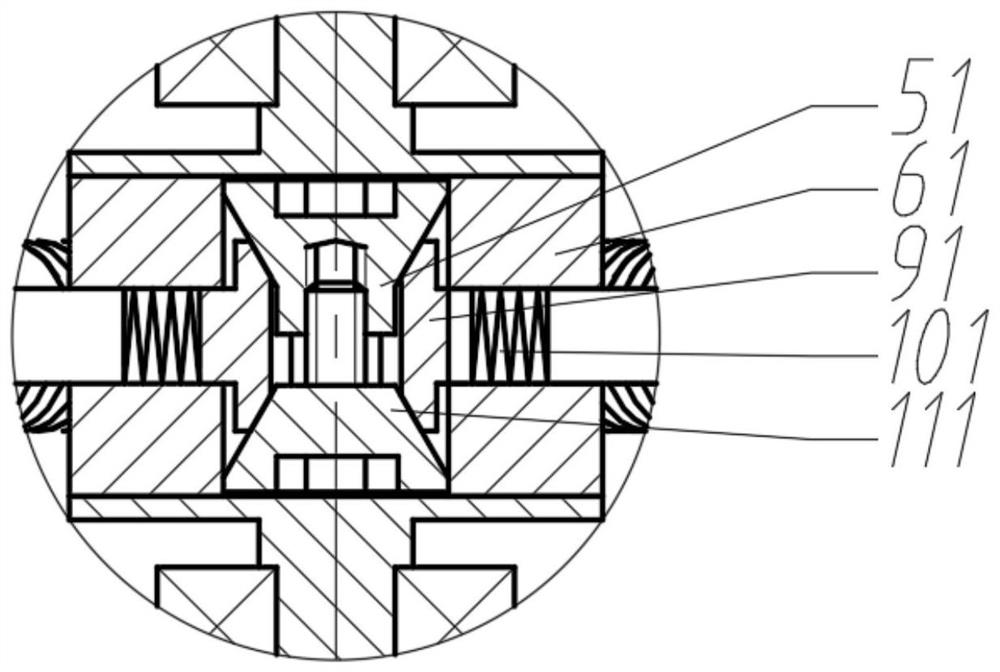

Method used

Image

Examples

Embodiment 1

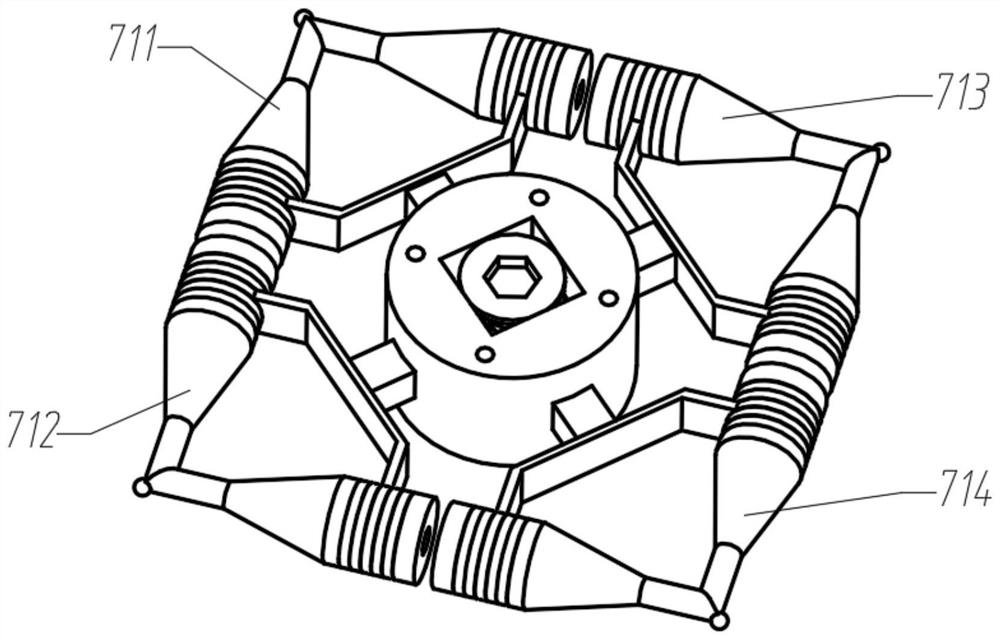

[0032] In this embodiment, the N V vibrators can generate driving force simultaneously or not at the same time (four V vibrators in the schematic diagram of the present invention). When the number of V vibrators is an even number, the V vibrators are numbered clockwise or counterclockwise. In the schematic diagram, they are numbered counterclockwise, such as image 3As shown, the two sandwich transducers of each V vibrator are divided into two phases, A and B. As shown in the figure, in this embodiment, the vibrators (711) and (713) are connected to phases A and B with a phase difference of 90°. Simple harmonic excitation signal, (712), (714) oscillator A phase access and (711), (713) oscillator A phase difference of 180 ° simple harmonic excitation signal, (712), (714) The phase B of the vibrator is connected to the simple harmonic excitation signal with a phase difference of 180° from the phase B of the vibrator (711) and (713). It can ensure that the contact of the V vibra...

Embodiment 2

[0034] In this embodiment, the four V oscillators generate driving force at the same time, and the excitation signal of each V oscillator is completely the same, that is, the same frequency and the same phase. If the phase difference of the two-phase excitation signals of V vibrator A and B is adjusted to -90°, the reverse rotation of the motor can be realized. Such as image 3 The four V oscillators of the rotor shown in the figure, (711), (712), (713), (714) oscillators A and B are connected to simple harmonic excitation signals with a phase difference of 90°, and the radial force of the rotor is balanced.

Embodiment 3

[0036] In this embodiment, the size of the included angle of the transducer is changed. By changing the angle between the two sandwich transducers of the V vibrator, the contact of the V vibrator can be controlled to form an elliptical motion. When the included angle is less than 90°, the ellipse formed by the V vibrator contact is prolate, such as Figure 8 As shown in (a), (82) is the movement track of the contact, which is oblong and elliptical, and the normal direction of the contact between the contact and the friction layer has a large amplitude, so when the contact and the friction layer rub against each other, a large friction force can be generated , so that the output torque of the motor is large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com