Storage box for print screen units

A technology for printing stencils and safes, applied in applications, home appliances, instruments, etc., can solve the problems of high loss risk, cumbersome and inconvenient label confirmation, eliminate time and personnel investment, improve convenience and accuracy, The effect of improving management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

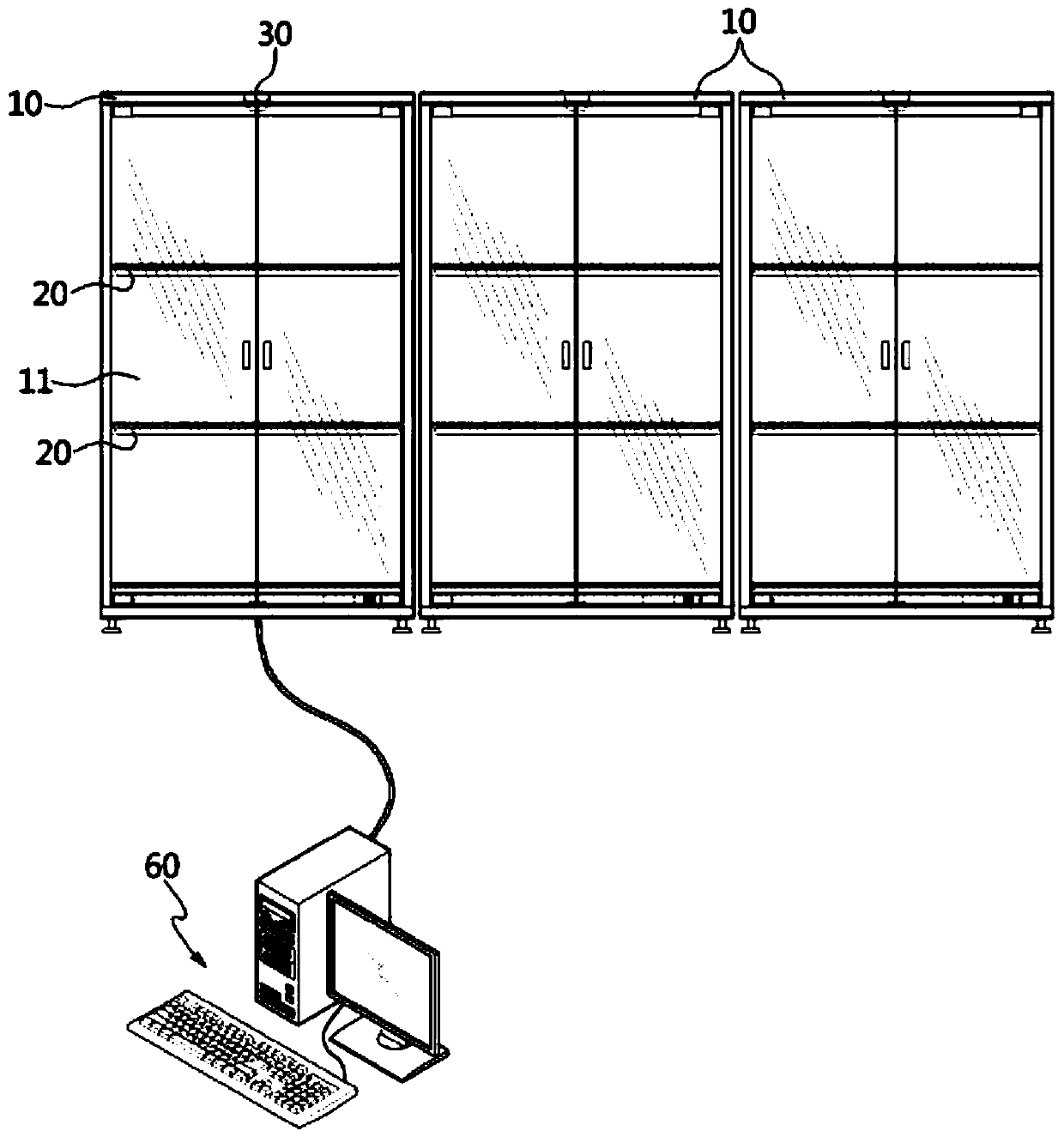

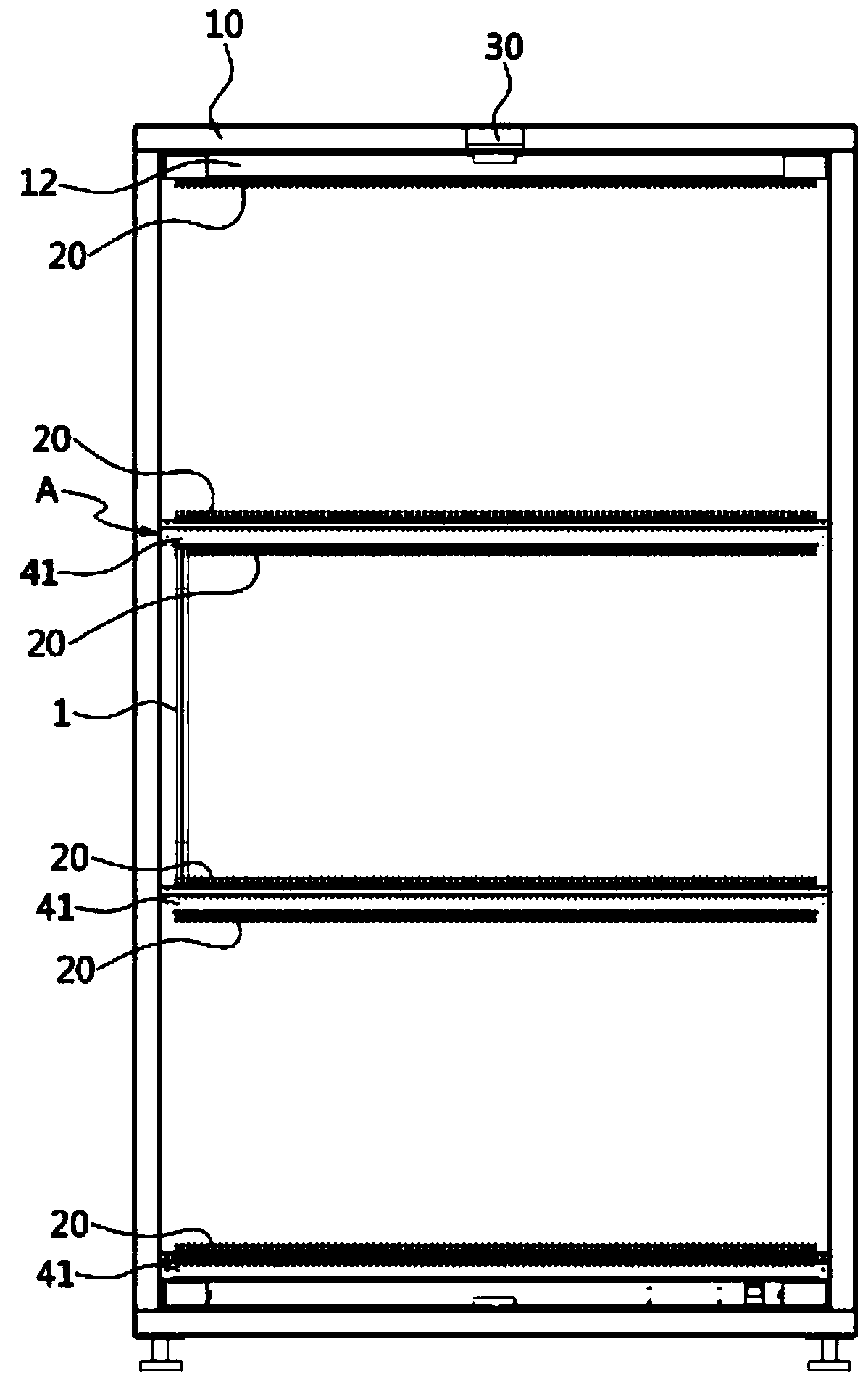

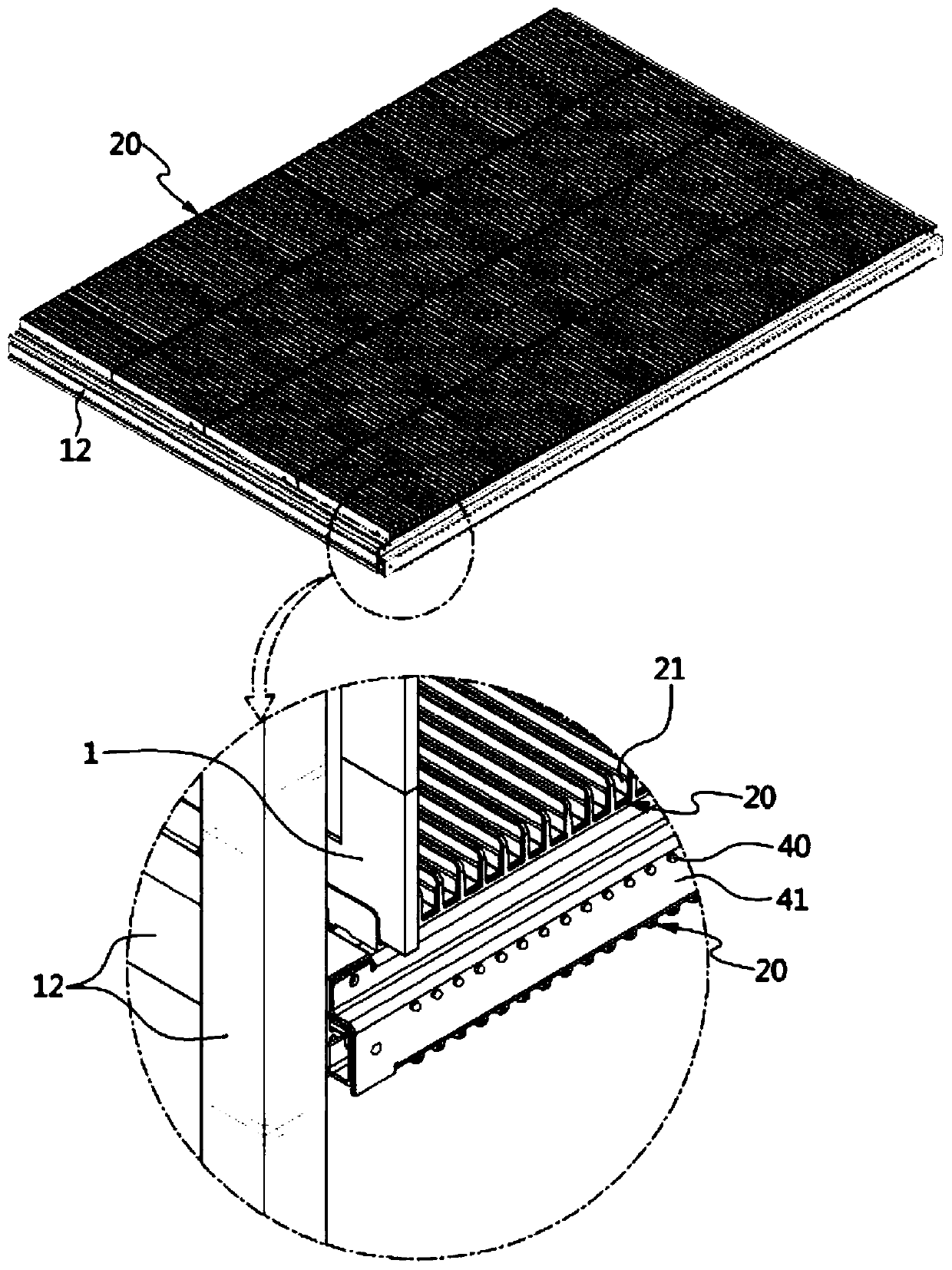

[0036] Refer to the following Figure 1 to Figure 5 Embodiments of the present invention will be described in detail.

[0037] The storage box for the printing screen unit of the present invention includes a box body 10, a plurality of slot racks 20, a main display portion 30, a plurality of slot display lamps 40, a control substrate 50, and a storage terminal 60. The plurality of printing screen units 1 stored in the box 10 in the form of a row is constructed as a database, and the opening of the box 10 for the printing screen unit 1 is opened by the computer program when the printing screen unit 1 is put in and out of the warehouse. The storage box is conveniently opened and notified of the location for the storage of the printing screen unit 1 in and out.

[0038] Described box body 10 is the upright type iron box shape of front opening, comprises: opening and closing glass door 11, and its hinge is combined in front opening and the inside of opening and closing safe depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com