Pressurised fluid flow system for a dth hammer and reverse circulation hammer based on same

A technology of pressurized fluid and flow system, which is applied in the direction of drilling drives, drill bits, earthwork drilling and production in the wellbore, which can solve the problems of negative impact of drill bit design, insufficient drag surface of keyway, increase of manufacturing cost, etc., and achieve deterioration cycle Efficiency, improved reliability, effect of increased passive volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

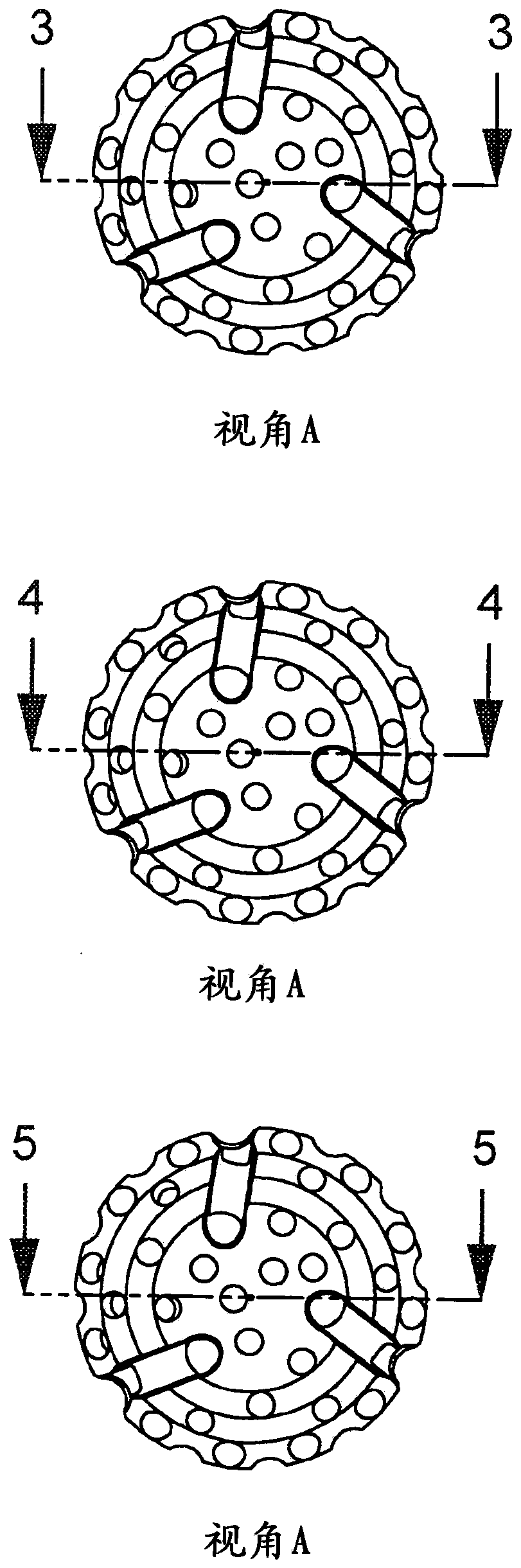

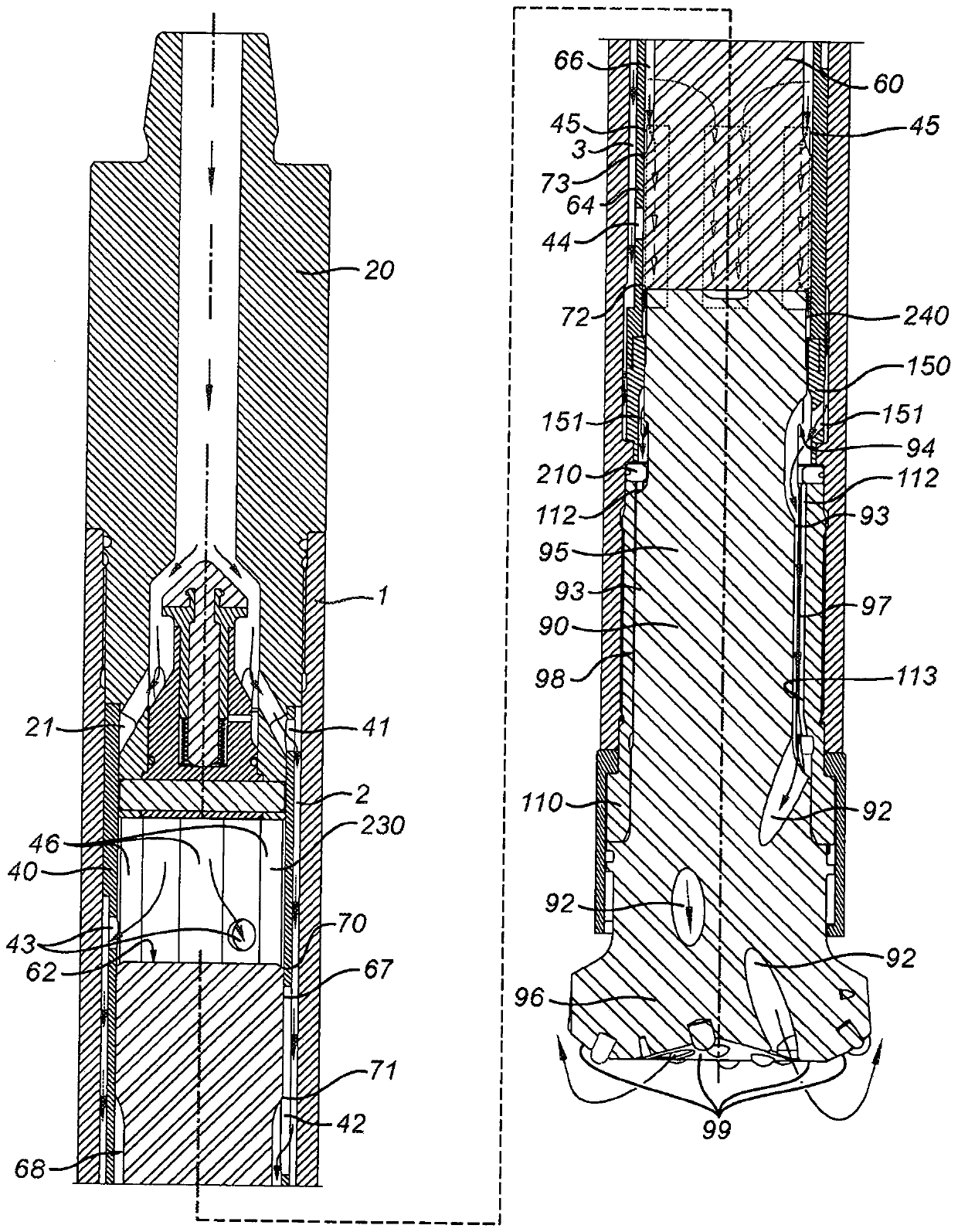

[0103] refer to Figure 1 to Figure 7 , showing a positive cycle DTH hammer, which includes the following main components:

[0104] a cylindrical housing (1) with a rear end and a front end;

[0105] a drive connector (110) mounted to the front end of said housing (1) and having an inner surface (113) with a keyway (112) machined thereon;

[0106] a rear connector (20) secured to the rear end of said housing (1) for connecting the hammer to a source of pressurized fluid;

[0107] a piston (60), which is slidably and coaxially arranged inside said casing (1), and said piston has a front chamber (240) and a rear chamber at opposite sides of said piston (60) (230) capable of reciprocating movement by pressure variation of pressurized fluid contained therein, said piston (60) having a plurality of outer sliding surfaces (64, 67); and

[0108]a drill bit (90) slidably mounted on said driver sub (110), the sliding movement of said drill bit (90) being limited by a bit holder (210...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com