Rectangular track beam of high-speed rail and processing technology thereof

A processing technology and track beam technology, which is applied to tracks, roads, buildings, etc., can solve the problems that the rectangular track beams of empty iron cannot meet the accuracy and size requirements, and achieve the goal of ensuring safe and stable operation, convenient operation, and scientific and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

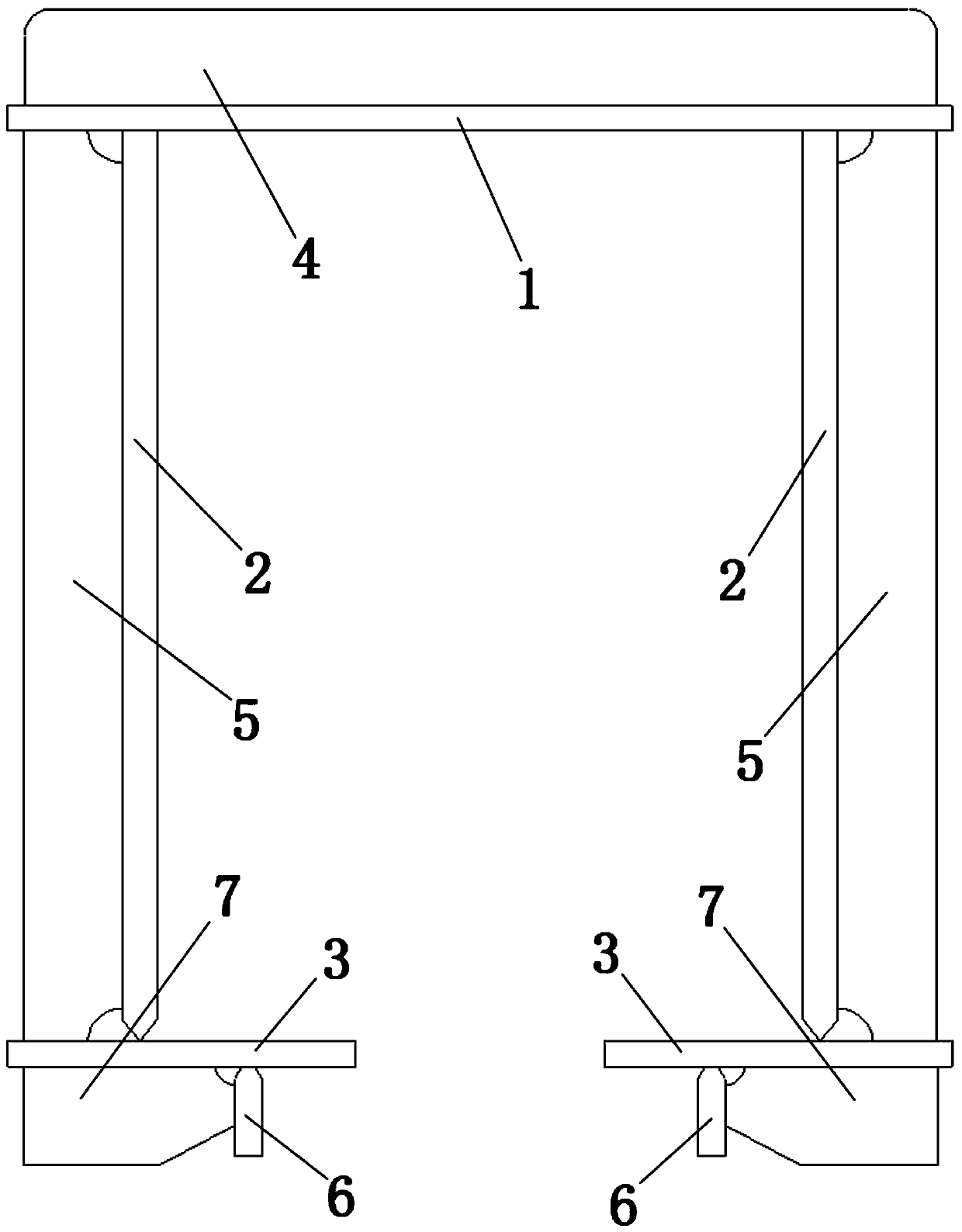

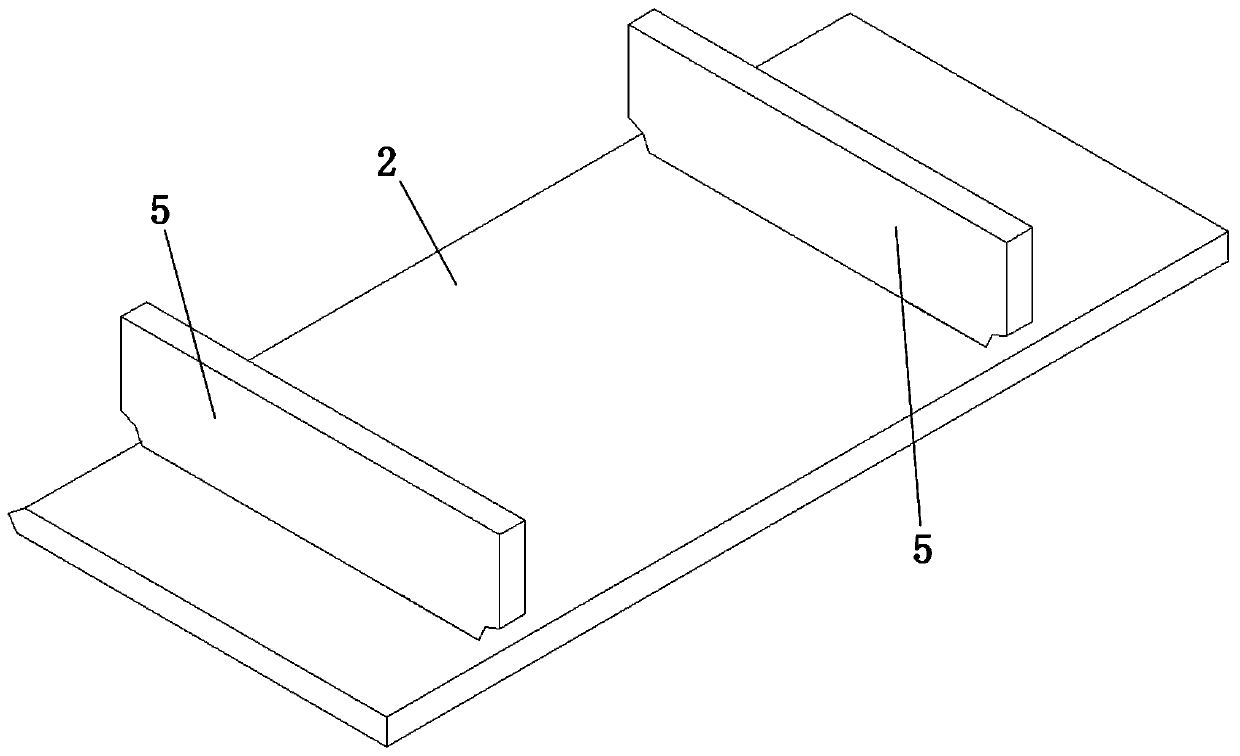

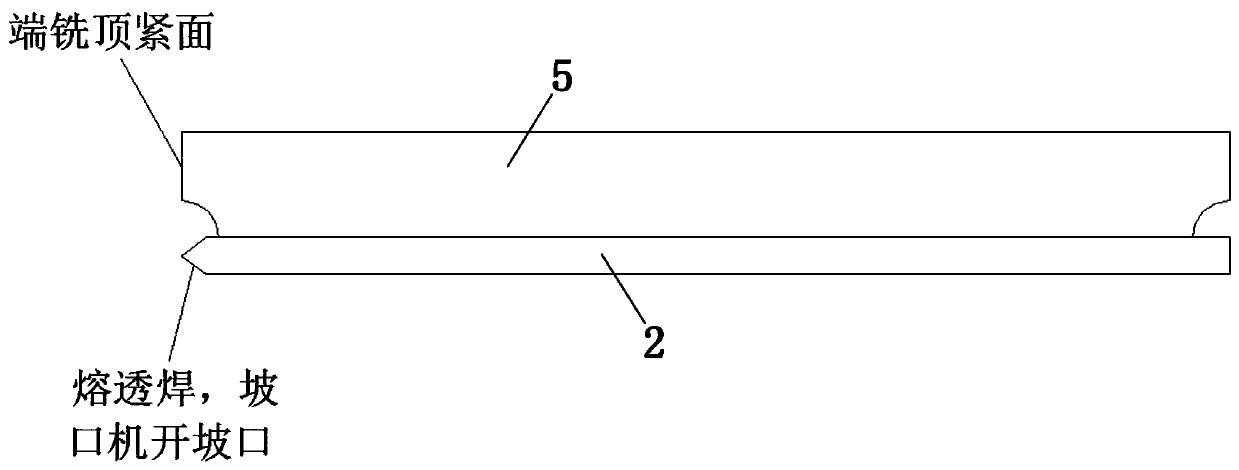

[0035] Such as Figure 1-9 As shown, the empty iron rectangular track beam provided by the present invention has wonderful conception, scientific and reasonable design, and convenient operation, which can effectively ensure the accuracy and size requirements of the empty iron rectangular track beam. The processed empty iron rectangular track beam has high precision and size conforms to The operating requirements of the air-rail monorail suspension vehicle can effectively ensure the safe and stable operation of the air-rail monorail suspension vehicle on the air-rail rectangular track beam. The present invention comprises a top plate 1 distributed horizontally, two web plates 2 vertically and vertically welded to both sides of the bottom surface of the top plate 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com