Method for Determining the Layout and Length of Stator Leads and Connections of DC Traction Motor

A DC traction and motor technology, applied in the manufacture of motor generators, motor components, electromechanical devices, etc., can solve the problems of inability to accurately calculate the length of the stator lead wires of DC traction motors, prolong the trial production period, etc., to shorten the production period, The operation process is convenient and concise, and the idea is wonderful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

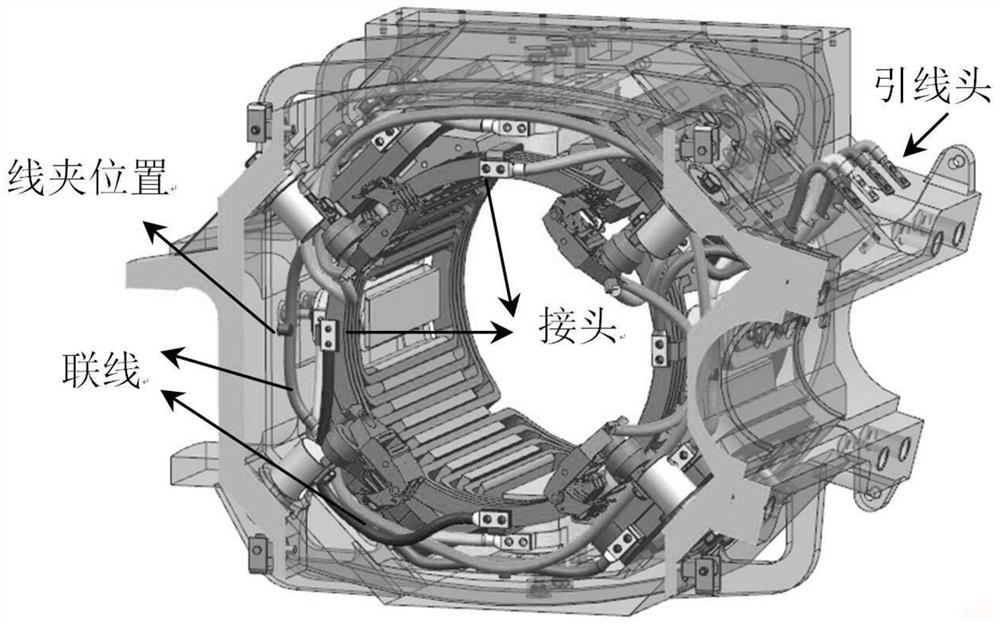

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

[0020] The method for determining the layout and length of the stator leads and connection lines of the DC traction motor provided by the present invention comprises the following steps:

[0021] Step 1. Using NX 3D software, conduct 3D modeling of the stator base, brush holder, and each winding, and assemble them into a stator assembly, so as to determine the position of each winding and brush holder joint in 3D space.

[0022] Step 2. Using WAVE (What-if Alternative Value Engineering) inter-component correlation modeling technology, copy the geometric information and spatial position of the joints in the stator assembly to each in-line part to be designed, that is, determine the Connector location for inline parts.

[0023] Step 3. The lead and connection joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com