Current loading device and current loading method

A loading device and current technology, which is applied in the field of heat treatment, can solve the problems of accurate access to the temperature zone and the inability to study the influence of pulse current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The purpose of the present invention is to provide a precise current loading device and a precise current loading method.

[0038] Below in conjunction with accompanying drawing, the present invention will be further described:

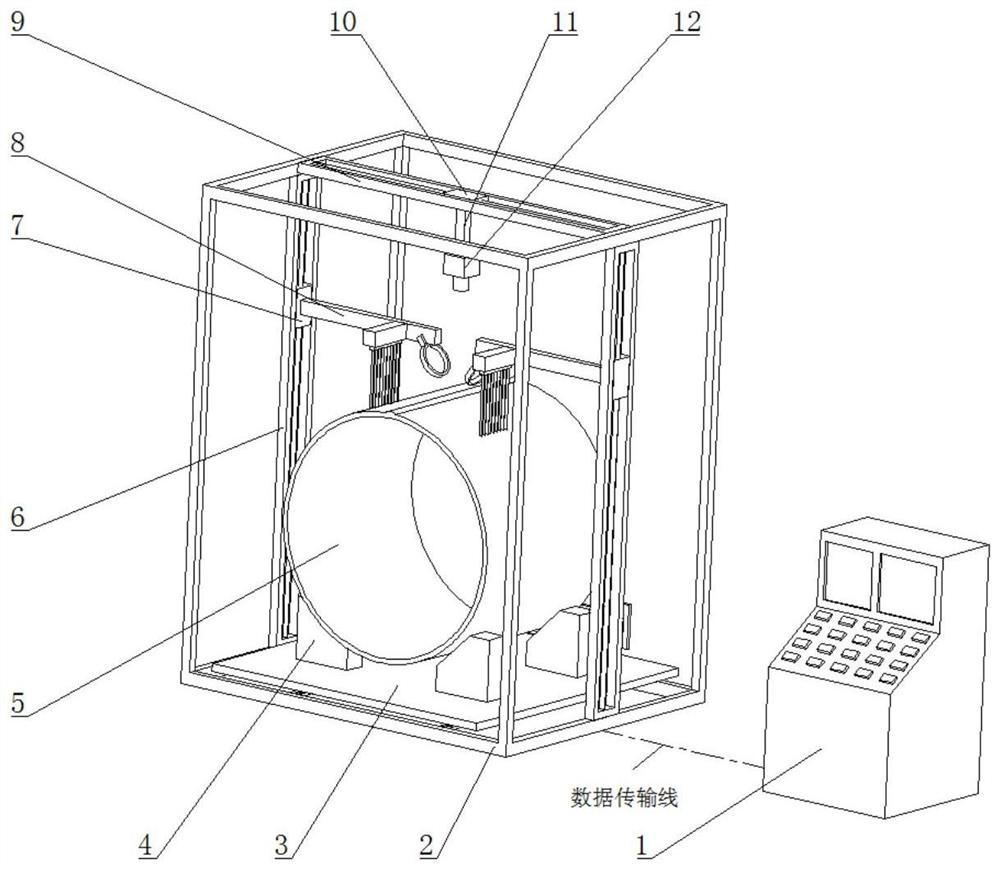

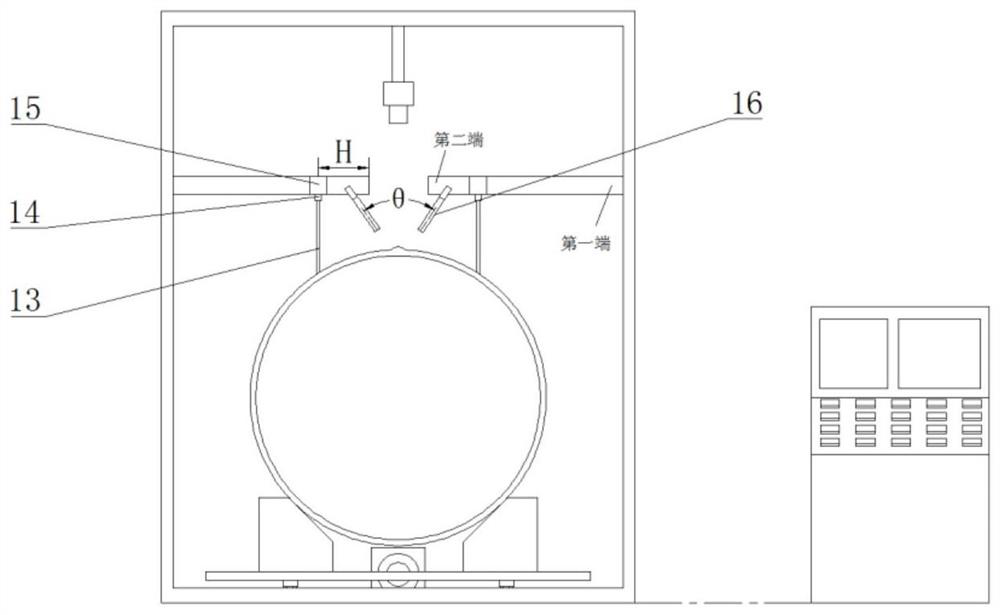

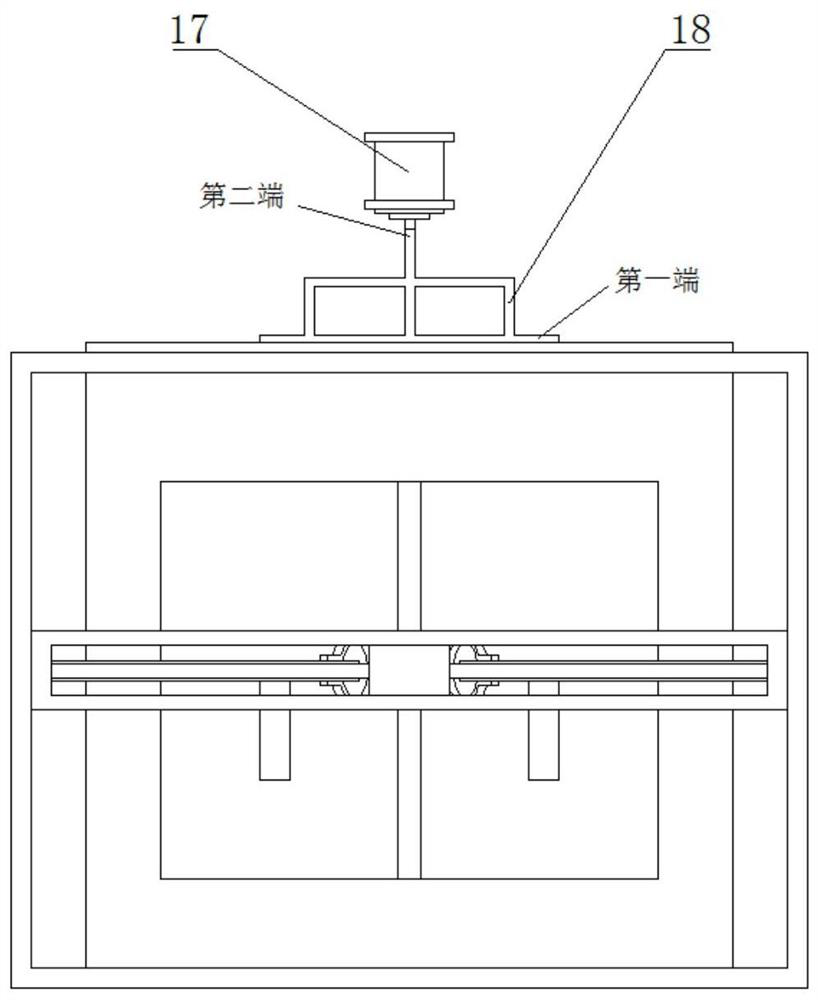

[0039] Such as figure 1 The current accurate loading device of the present invention shown includes a total support 2, two clamping devices 8, an induction coil 16, an upper connecting rod 11, a temperature vision camera system 12, a sliding subsystem, a computer processing terminal 1 and a pulse current subsystem.

[0040] The total bracket includes a frame, a side bracket and an upper bracket. A sliding groove parallel to one side of the frame is fixedly installed on the bottom of the frame. The sliding groove can ensure the smooth movement of the sliding bottom plate 3 and is placed on the edge of the longitudinal seam welded pipe 5 on the sliding bottom plate 3. Linear movement ensures the stability of induction heating; two side brackets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com