Clothes treatment device

The technology of a clothes processing device and a rectifying device, which is applied in the field of clothes processing, can solve problems such as low drying efficiency and limited heater installation position, and achieve the effects of improving heating efficiency, reducing magnetic field strength, and weakening magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

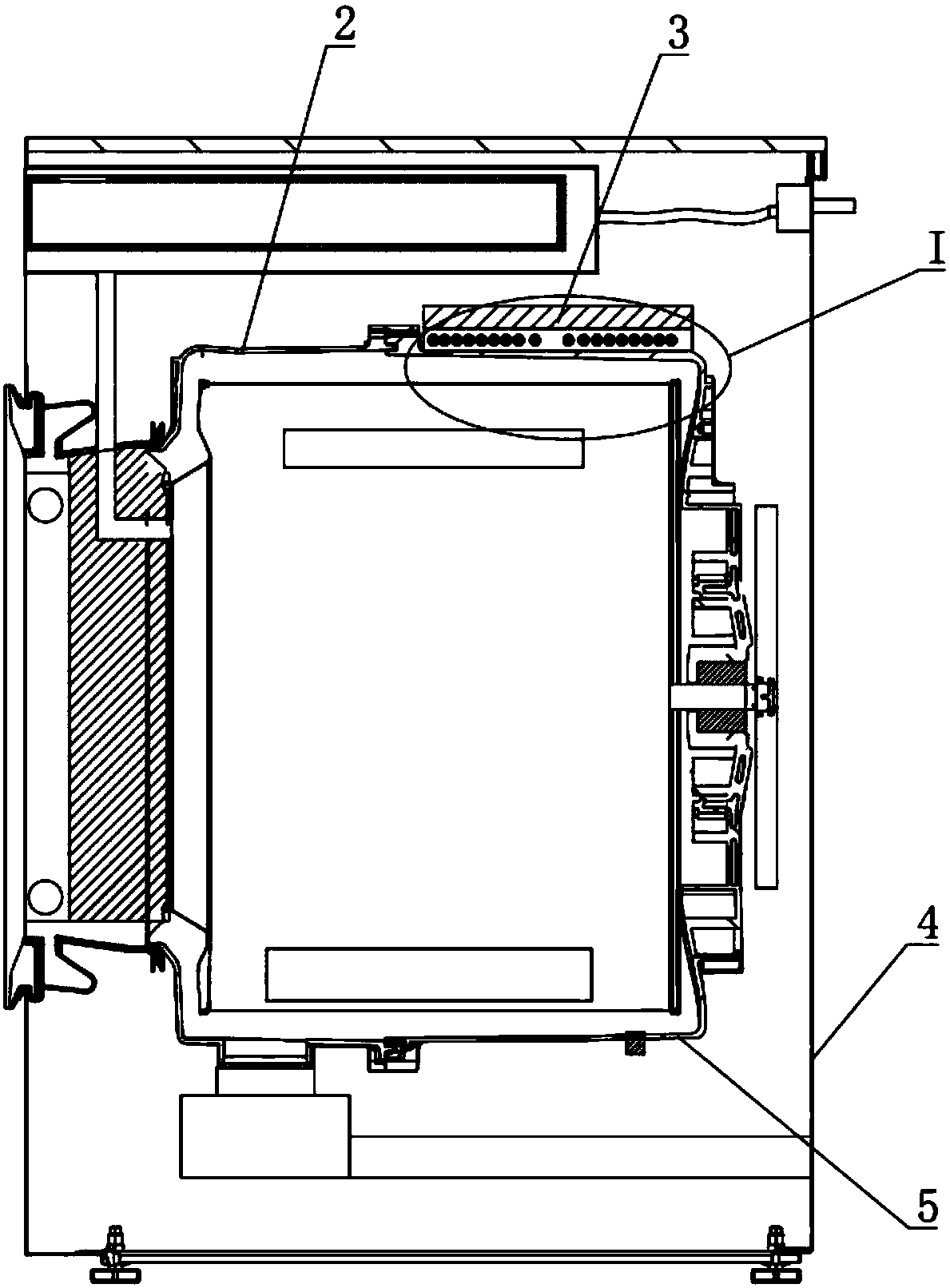

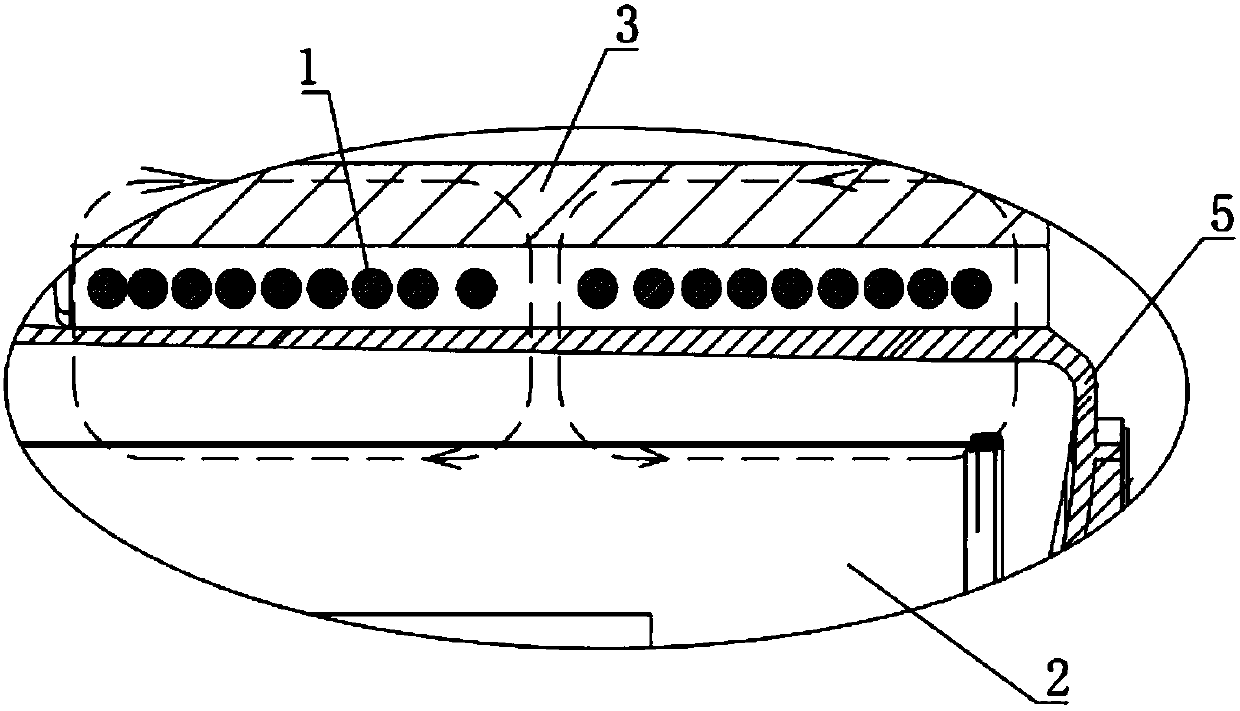

[0033] Such as figure 1 with figure 2 As shown, this embodiment provides a clothes treatment device, including a rectifier capable of generating high-frequency alternating voltage, a coil 1 powered by the rectifier, and a high-frequency alternating magnetic field generated by the coil 1 Within the range and made of magnetically conductive and conductive materials, the rotating drum within the range of the high-frequency alternating magnetic field generated by the coil 1 generates eddy currents to heat itself during rotation. The specific principles are: The coil 1 and the rotating cylinder form a transformer, the coil 1 is the primary coil, and the rotating cylinder forms the secondary coil, so that an induced eddy current is generated inside the rotating cylinder to make it self-heating. The clothes processing device is a drum washing machine, a pulsator washing machine, or a non-porous inner barrel washing machine. The drum washing machine is taken as an example in this em...

Embodiment 2

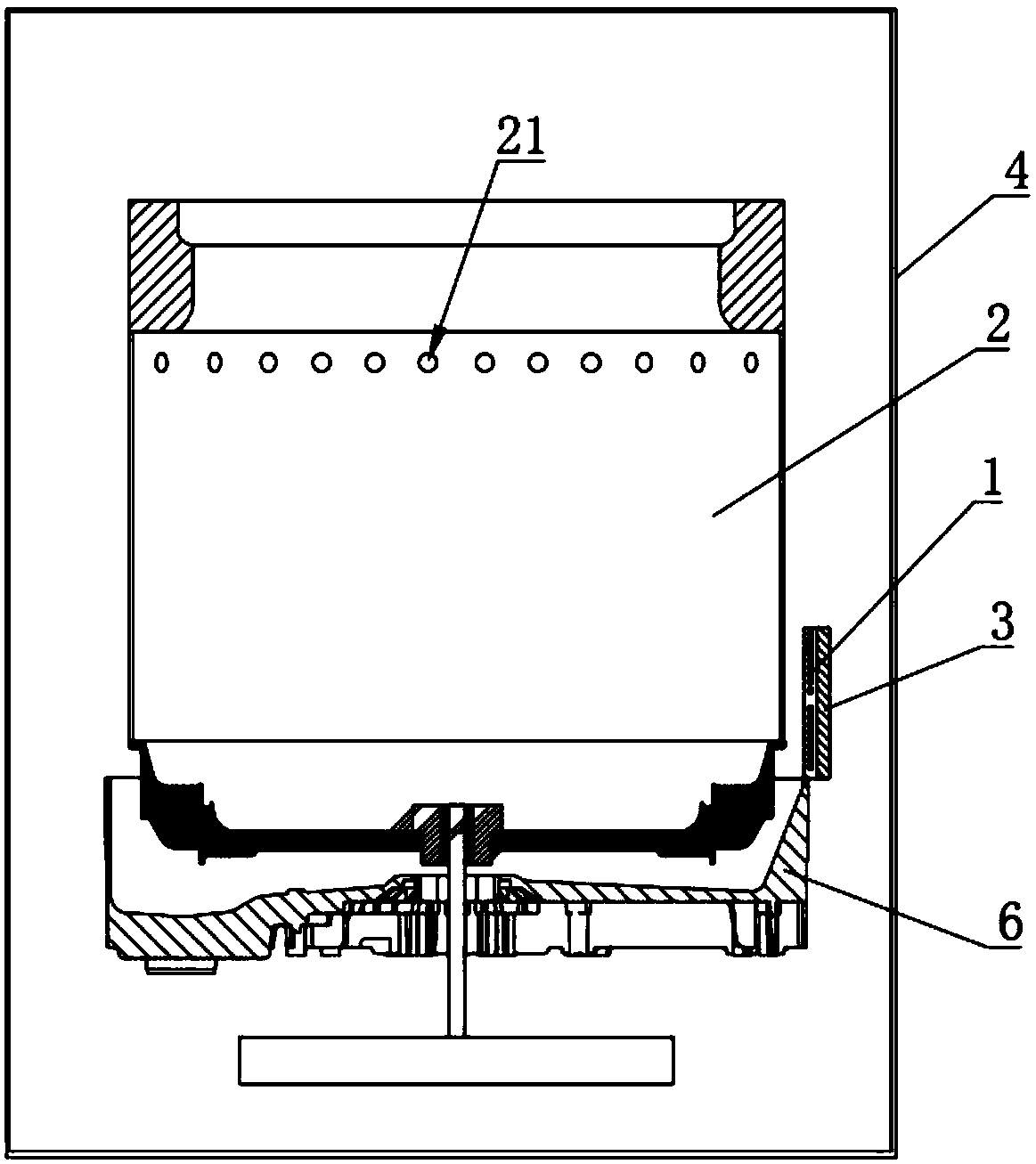

[0047] In this embodiment, the clothes processing device is a washing machine with a non-porous inner tub, such as image 3 As shown, the clothes processing device does not have an outer cylinder, the rotating cylinder is the inner cylinder 2 and placed vertically, the rotating cylinder is made of stainless steel, and the upper part of the rotating cylinder is provided with a centrifugal hole 21, and the coil 1 is far away from the centrifugal hole 21 is set; the bottom of the rotating cylinder is provided with a catchment pan 6, through which the water discharged from the centrifugal hole 21 is received. The coil 1 is connected to the water collecting tray 6 through the fixing frame 3, because the fixing frame 3 is made of insulating material, and the coil 1 is sealed by the insulating material, so that the coil 1 will not touch the water and play a protective role.

Embodiment 3

[0049] In this embodiment, the clothes processing device is a pulsator washing machine, such as Figure 4 As shown, the inner cylinder 2 is placed vertically, and the coil 5 is arranged on the side wall of the outer cylinder 1 . Specifically, the coil 1 can be arranged on the side wall of the outer cylinder 5 and arranged close to the middle or lower part of the outer cylinder 5 . In this embodiment, the coil 1 is arranged near the middle of the outer cylinder 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com