Spinning type current-splitting wire clamp

A shunt line and splint technology, applied in the direction of the cable suspension device, etc., can solve the problems that affect the safe and reliable operation of the transmission line, loose connection bolts of the diversion plate, poor contact of the diversion plate, etc., and achieve good practical use and promotion value, structure Simple and practical design, time-saving and labor-saving installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

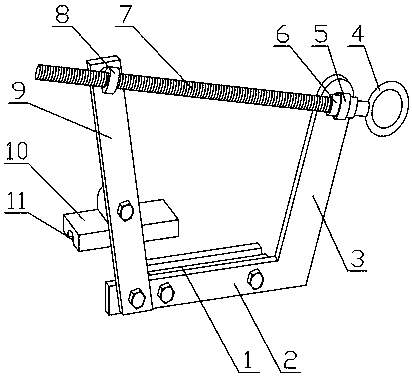

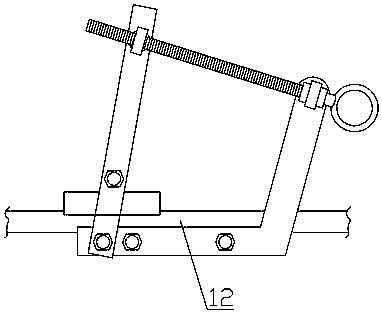

[0014] see figure 1 , figure 2 , the present invention is a spinning type shunt clamp, which has an L-shaped mounting plate, the L-shaped mounting plate is composed of a horizontal plate 2 and a slanting plate 3, and a lower splint is fixed on the rear side of the horizontal plate 1. There is a cable groove on the lower splint, a rotating connecting plate 9 is hinged on the front side of the horizontal plate, and a rotating threaded collar 8 is provided on the upper front side of the rotating connecting plate; the inclined plate A rotating non-threaded collar 5 is arranged on the upper front side of the upper part, and an adjusting screw 7 is installed between the rotating threaded collar and the rotating non-threaded collar. The collar is idlingly connected, and the adjustment screw is provided with an adjustment handle 4 at one end of the rotating non-threaded collar, and an idling limit block 6 is also provided on the two sides of the rotating non-threaded collar on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com