Prosthetic knee with a rectification hydraulic system

A technology of prosthetics and ports, applied in the field of prosthetic knee joints with a corrected hydraulic system, can solve the problems that the hydraulic system affects the performance and cost of prosthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

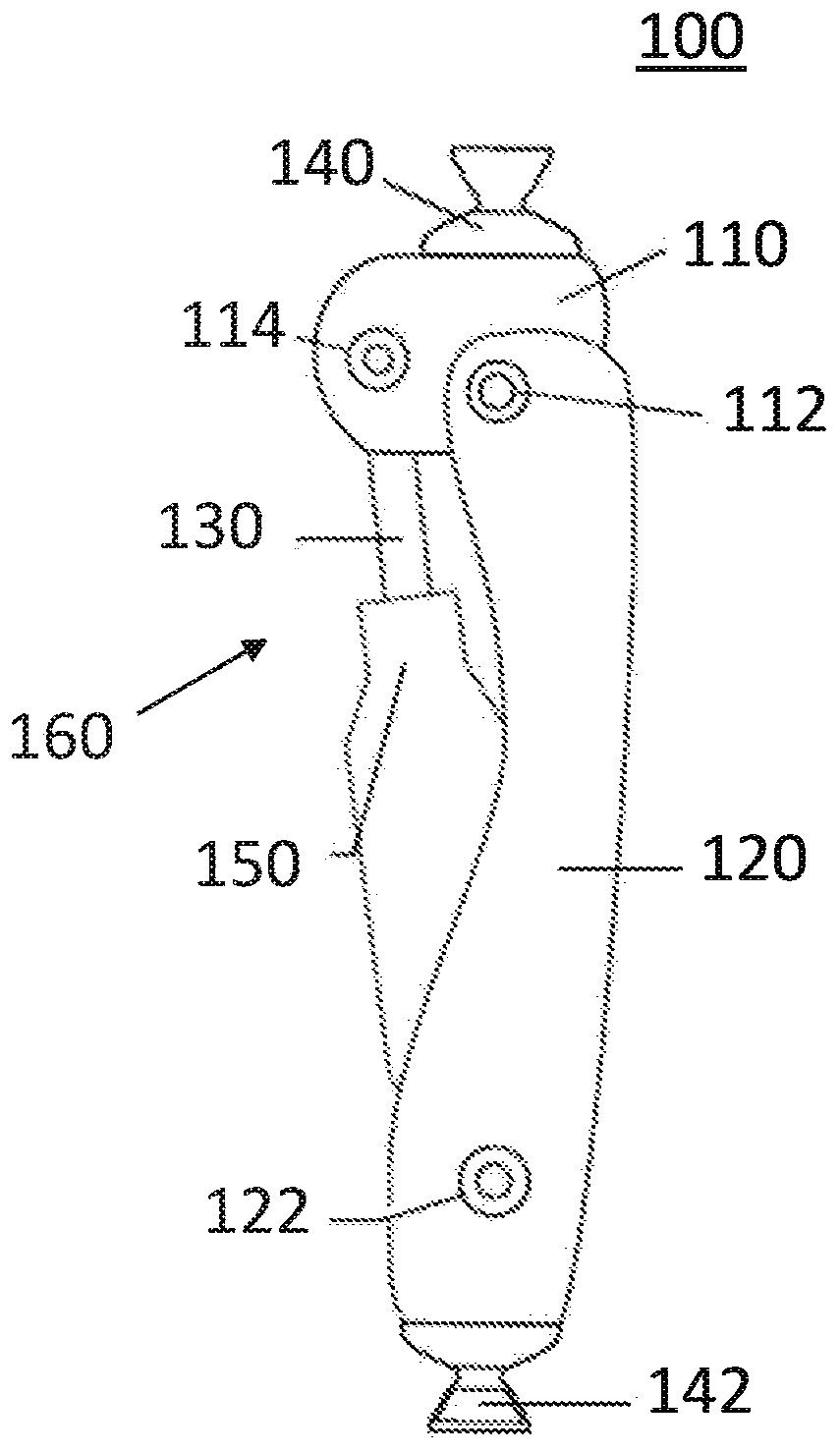

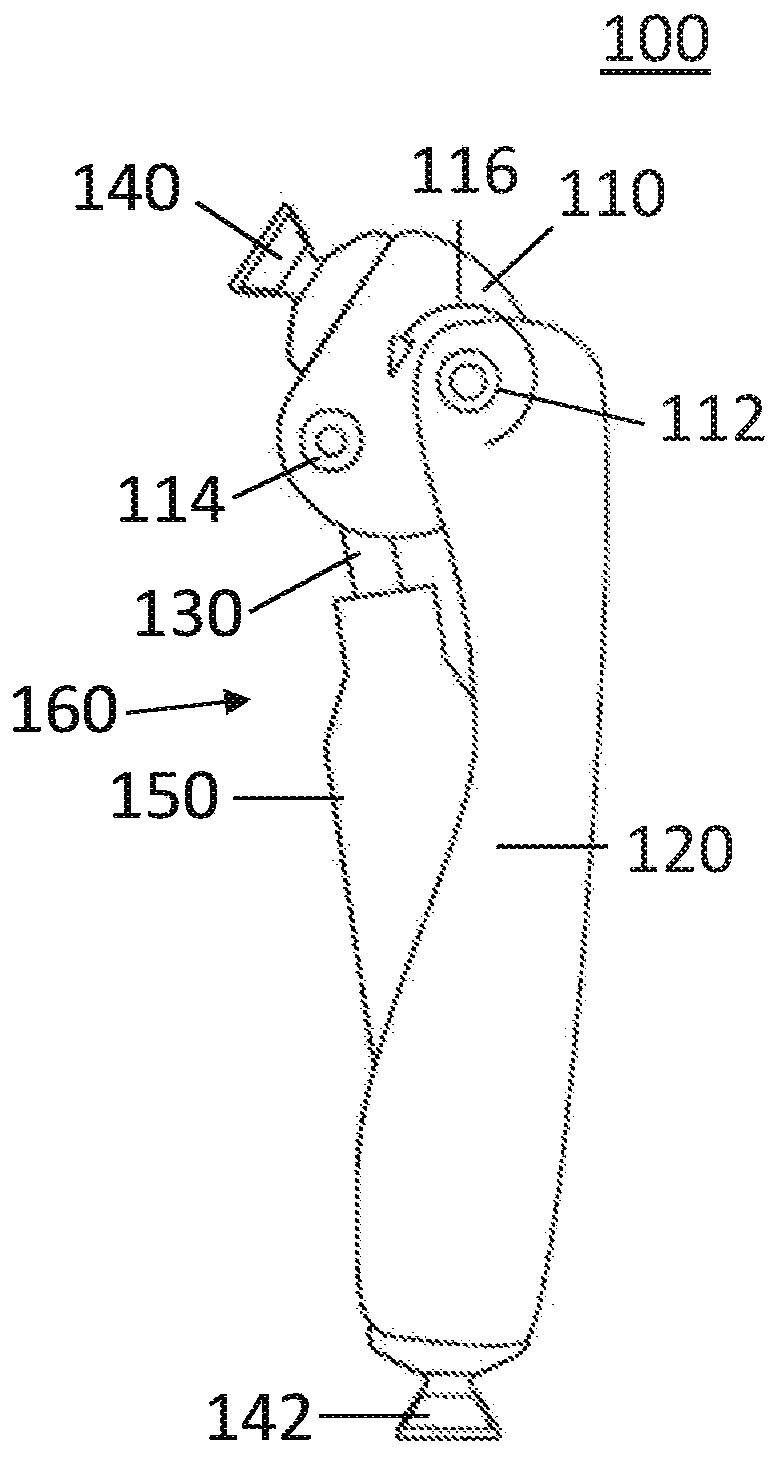

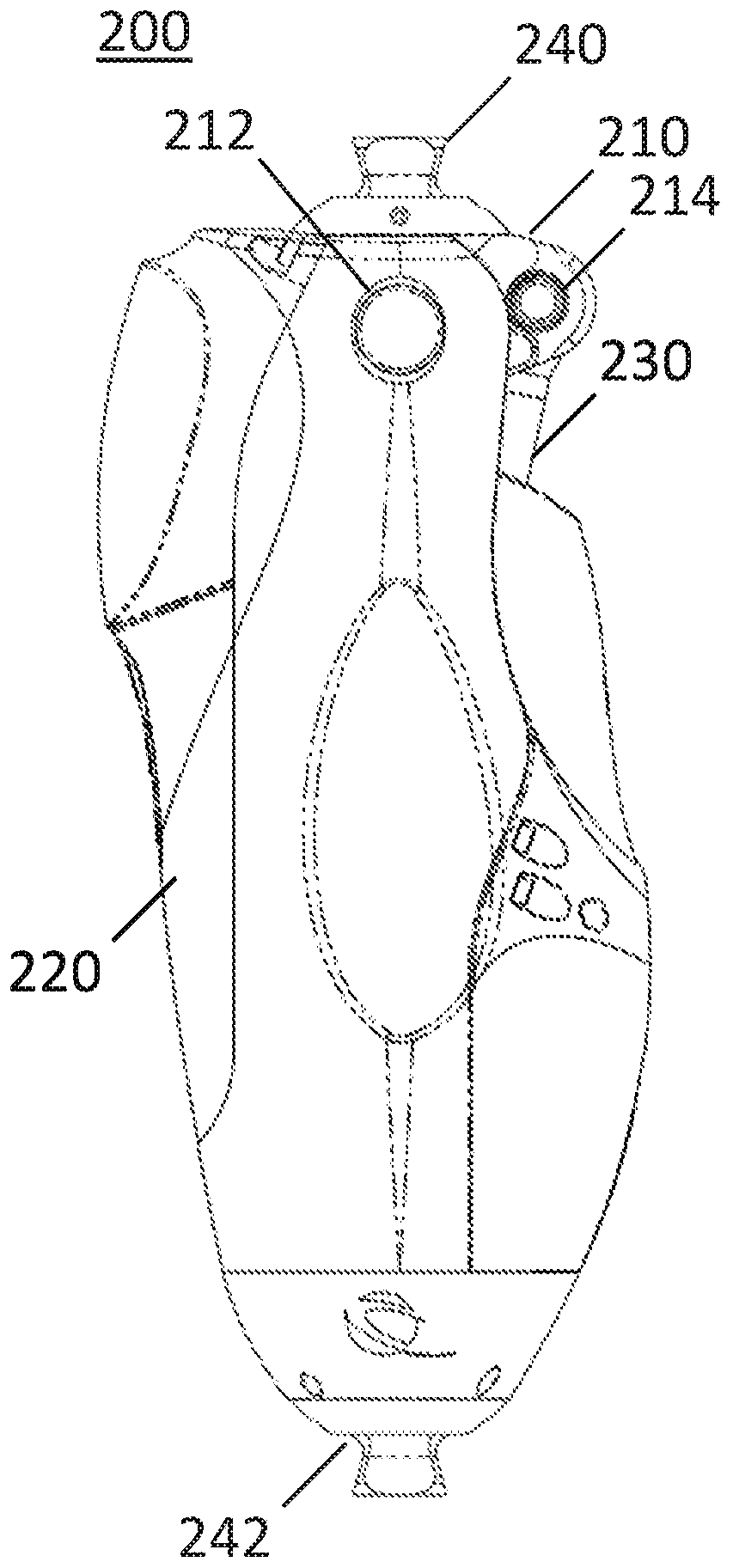

[0033] Described herein are hydraulic components, prosthetic systems, and methods for controlling hydraulic components or prosthetics. A microprocessor may be used to control a prosthetic joint as described herein to adjust the resistance of the joint based on the user's gait phase. In variations where the prosthetic joint includes a hydraulic system including a hydraulic cylinder and piston, the microprocessor may be configured to adjust the hydraulic fluid control valve to set the resistance of the hydraulic fluid through the hydraulic system for different phases of the gait cycle. In some variations, the hydraulic system may include components (eg, valves, fluid passages) to set the resistance of hydraulic fluid through the hydraulic system during power loss for different dynamic phases.

[0034] I. System

[0035] A. Prosthetic knee joint

[0036] Described here is a prosthetic used by amputees. In some variations, the prosthetic joints shown herein may be configured as p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap