Automatic control fire extinguishing system for forest fire fighting

A fire-extinguishing system and fire-fighting technology, applied in the parts of the TV system, fire rescue, TV and other directions, can solve the problem that the fire-fighting equipment cannot both find the fire source, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

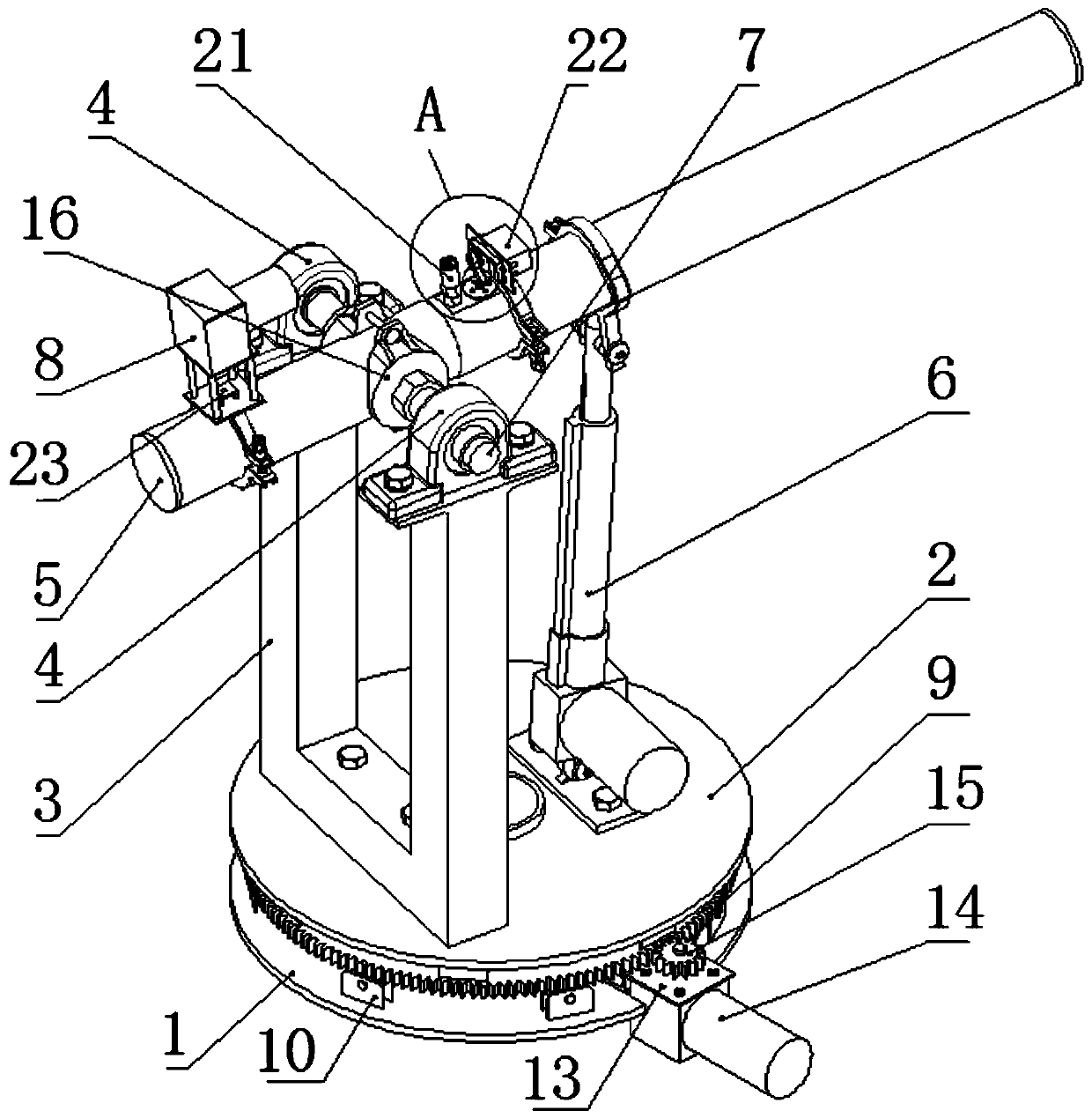

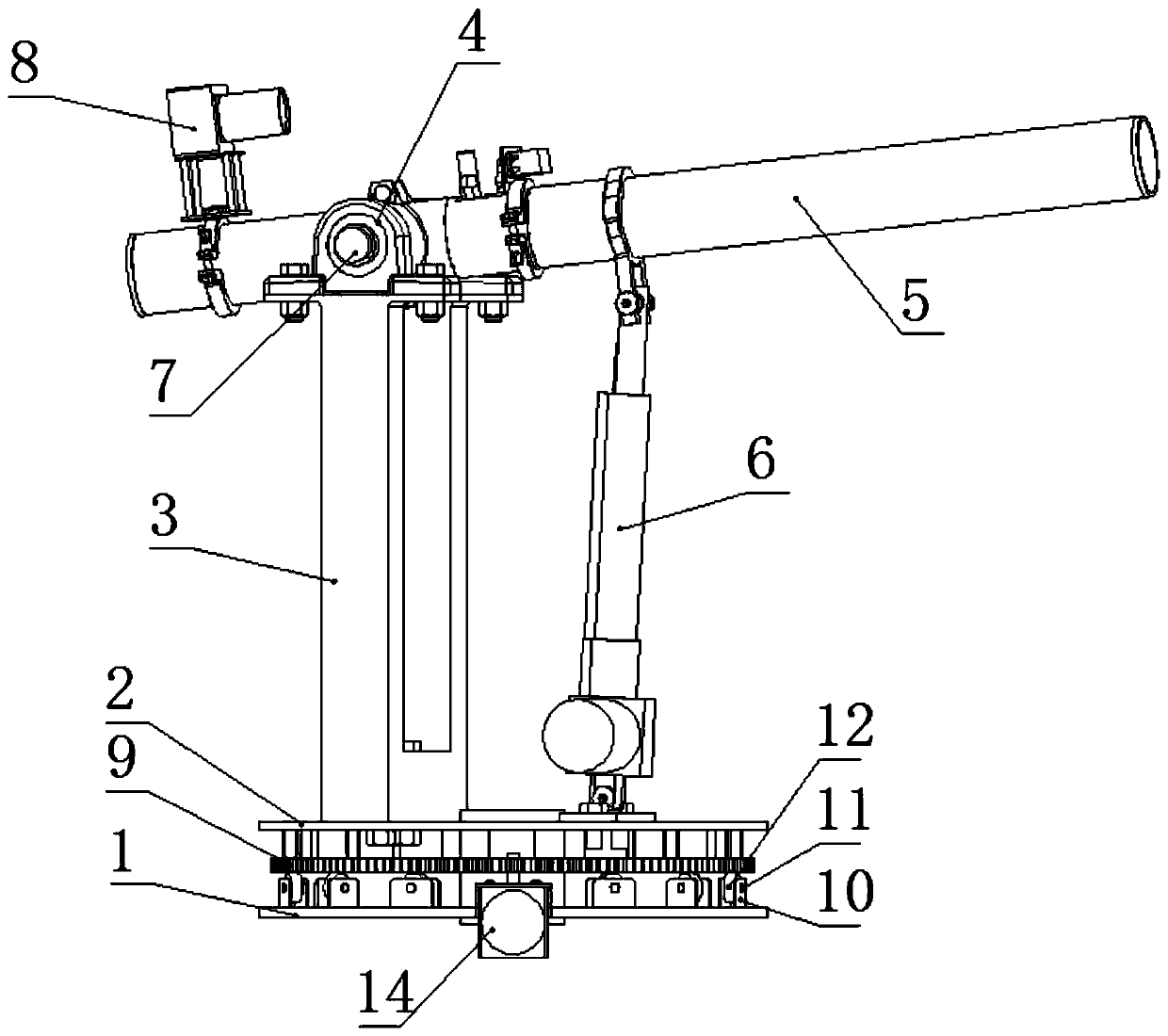

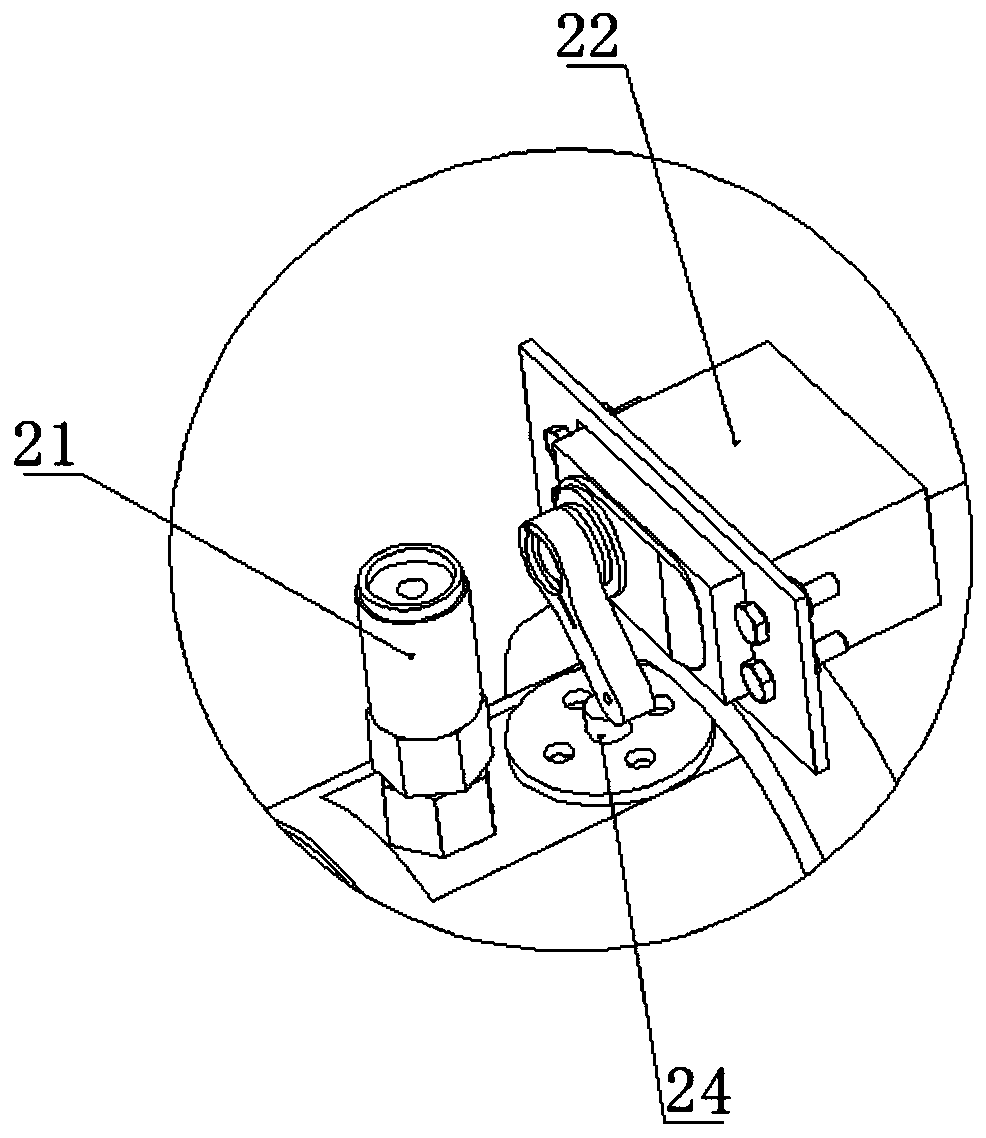

[0022] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a forest fire automatic control fire extinguishing system in this embodiment, it has two degrees of freedom, including base 1, rotating seat 2, bracket 3, bearing seat 4, fire water gun body 5 and electric push rod 6 , the rotating base 2 is mounted on the base 1 in rotation, the support 3 is installed on the upper end surface of the rotating base 2, the bearing seat 4 is installed on the top of the supporting frame 3, the rotating shaft 7 is installed in the bearing seat 4, and the fire water gun body 5 is fixedly installed on the rotating shaft 7, an electric push rod 6 is also installed on the described swivel seat 2, and the output end of the electric push rod 6 is connected with the fire-fighting water gun body 5, and a camera 8 is set on the fire-fighting water gun body 5. In this way, the control system has two degrees of freedom, one of which is that the rotating base 2 can...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination Figure 1 to Figure 5 Describe this embodiment, a kind of forest fire automatic control fire extinguishing system of this embodiment, the bottom end surface of described rotating seat 2 is equipped with external gear plate 9, the upper end surface of described base 1 passes through roller bracket 10, and roller bracket On the 10, a roller 12 is installed by rolling the roller shaft 11, and the roller 12 is used to support the external tooth gear plate 9, and a reduction motor support 13 is also installed on the base 1, and a reduction motor 14 is installed on the reduction motor support 13, The output end of the reduction motor 14 is equipped with a driving gear 15, and the driving gear 15 meshes with the externally toothed gear plate 9. So set up, in this embodiment, a technical solution is proposed to realize the rotation movement of the rotating base 2 relative to the base 1. The rotating base 2 is installed on the roller...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 1 to Figure 5 Describe this embodiment, a forest fire automatic control fire extinguishing system of this embodiment, the support 3 is a "gantry", and the top of the support 3 is installed with two symmetrically arranged bearing seats 4. In this way, two bearing blocks 4 are installed on the support 3, and the rotating shaft 7 is installed on the bearing blocks 4 through bearing rotation. The two symmetrically arranged bearing blocks 4 can effectively ensure the smooth rotation of the entire rotating shaft 7. The fire water gun body 5 adopts a fixed Sleeve is installed on the rotating shaft 7, and its fixed cover is to hold clamp pipe clip, clamping ring, fixed ring, and the fire water gun gun body 5 after the installation is vertical state with rotating shaft 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com