Method for designing live-wire high-lift fire extinguishing equipment for electric transmission line mountain fire

A transmission line and design method technology, which is applied in the field of transmission line mountain fire prevention, can solve the problems of range and insulation performance that cannot meet the fire extinguishing requirements of transmission line mountain fires, and achieve the effects of reducing flow, improving insulation performance, and improving fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

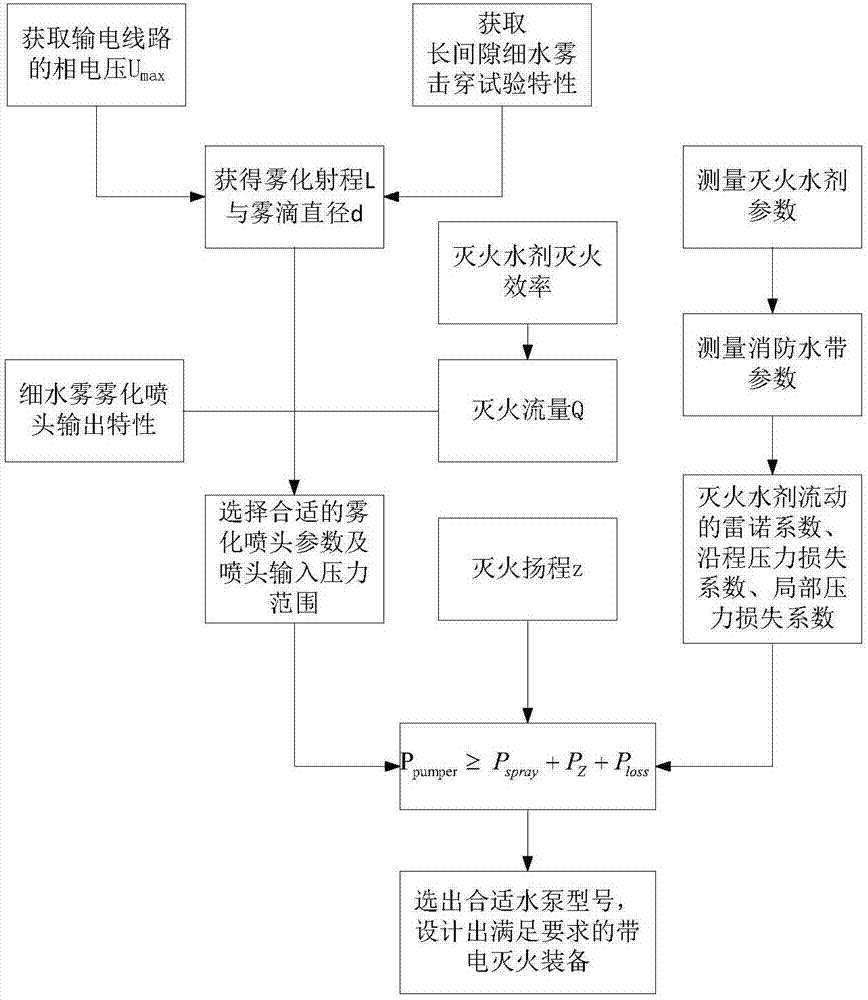

[0064] Such as figure 1 As shown, a method for designing high-lift fire extinguishing equipment for mountain fires on transmission lines according to an embodiment of the present invention includes:

[0065] Step 1. For UHV transmission lines in the range of 110kV-1000kV, the discharge of conductors to the ground or to firefighters is single-phase conductor discharge, and the maximum phase voltage U max It is 578kV.

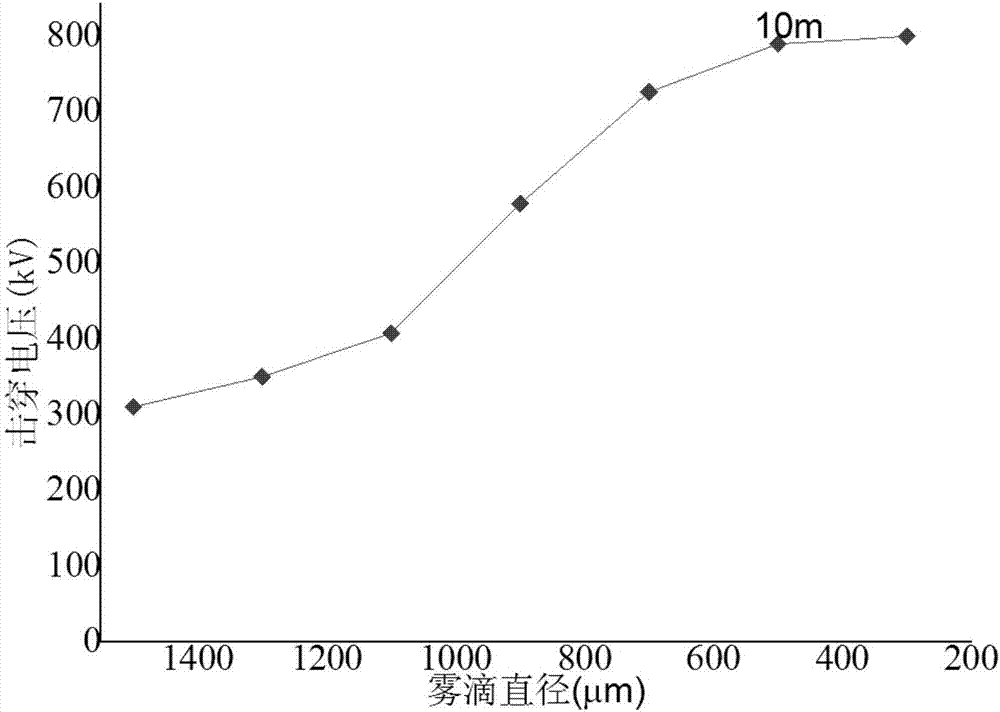

[0066] Step 2, according to the long gap water mist breakdown test characteristic curve and the maximum phase voltage U obtained by the long gap water mist breakdown test device max , select the fire extinguishing equipment to meet the requirements of the fine water mist atomization range L and droplet diameter d. Specifically include:

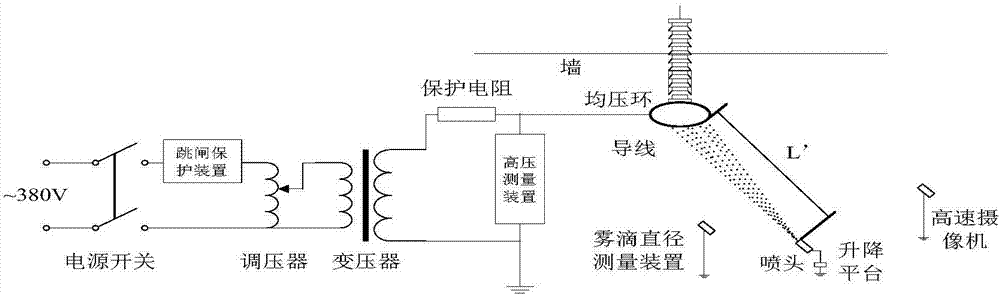

[0067] Step 201, building a fine water mist atomization insulation test ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap