Adjusting type automatic positioning device for bottle blowing machine

An automatic positioning and adjustment technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of multi-standard product positioning and unreasonable structure, non-adjustable positioning position, inaccurate positioning, etc., and achieve simple and reasonable structure , wide application range, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

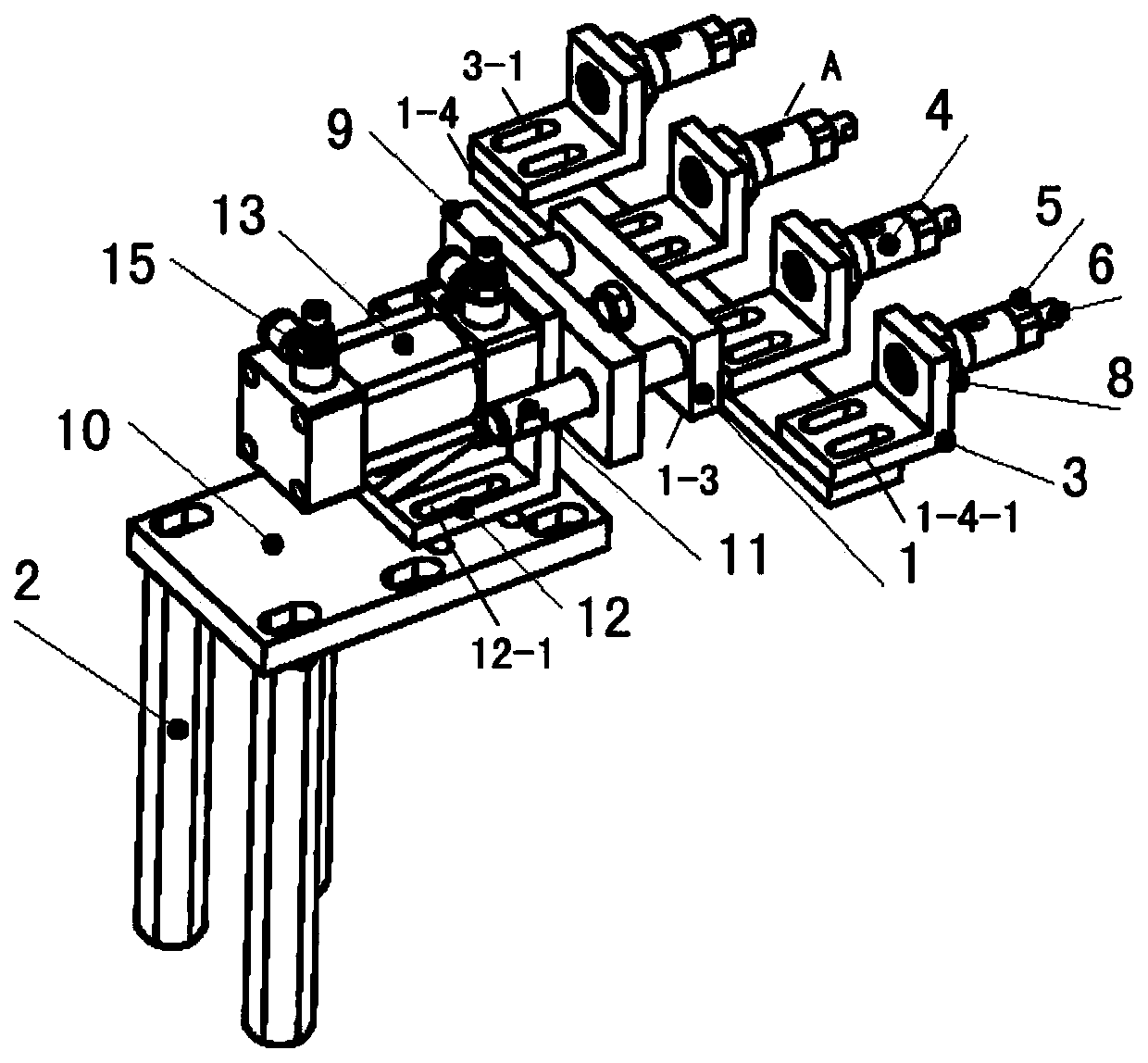

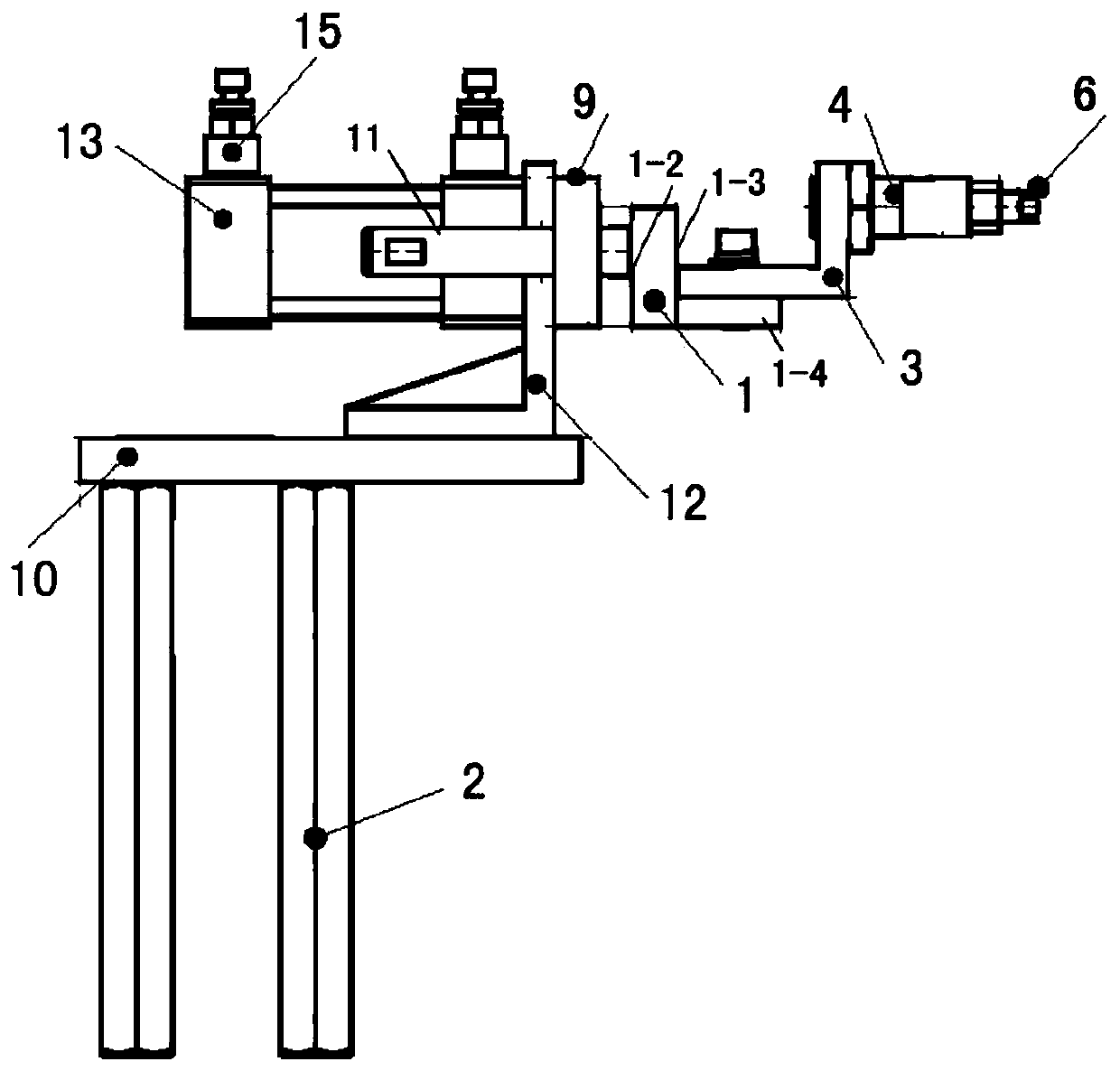

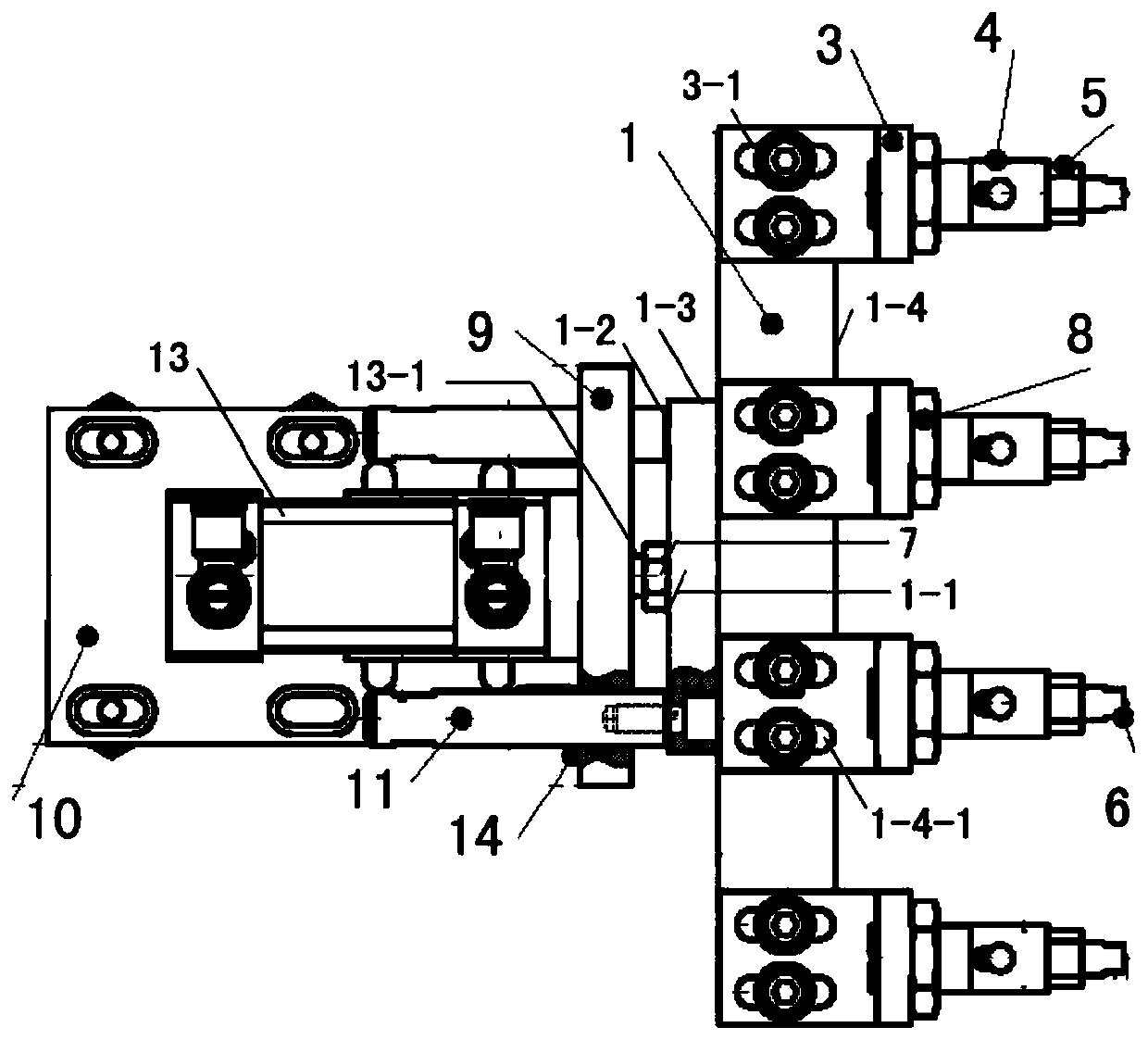

[0026] figure 1 to image 3 Constitute a specific embodiment of the present invention.

[0027] refer to Figure 1 to Figure 3 , the present embodiment includes a support seat 2, a support plate 10, a guide plate 9, a cylinder 13 and a control signal input end, the support plate 10 is arranged on the support seat 2, the cylinder 13 is arranged on the support plate 10, and a positioning adjustment member 1 is also included , the front end of the positioning adjustment member 1 is provided with a screw connection port 1-1 and a support connection end 1-2, the screw connection port 1-1 is the power input end of the positioning adjustment member 1 and is used to connect the piston rod 13 of the cylinder 13 -1, the support connecting end 1-2 is used to connect the guide rod 11 and constitute the sliding support structure of the positioning adjustment part; There is a front and rear position adjustment connection structure to adjust the relative position between the two, which co...

specific Embodiment 2

[0039] The characteristic of the specific embodiment 2 of the present invention is that two, three, five or six to ten positioners A are connected to the positioning adjustment member 1 . All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com