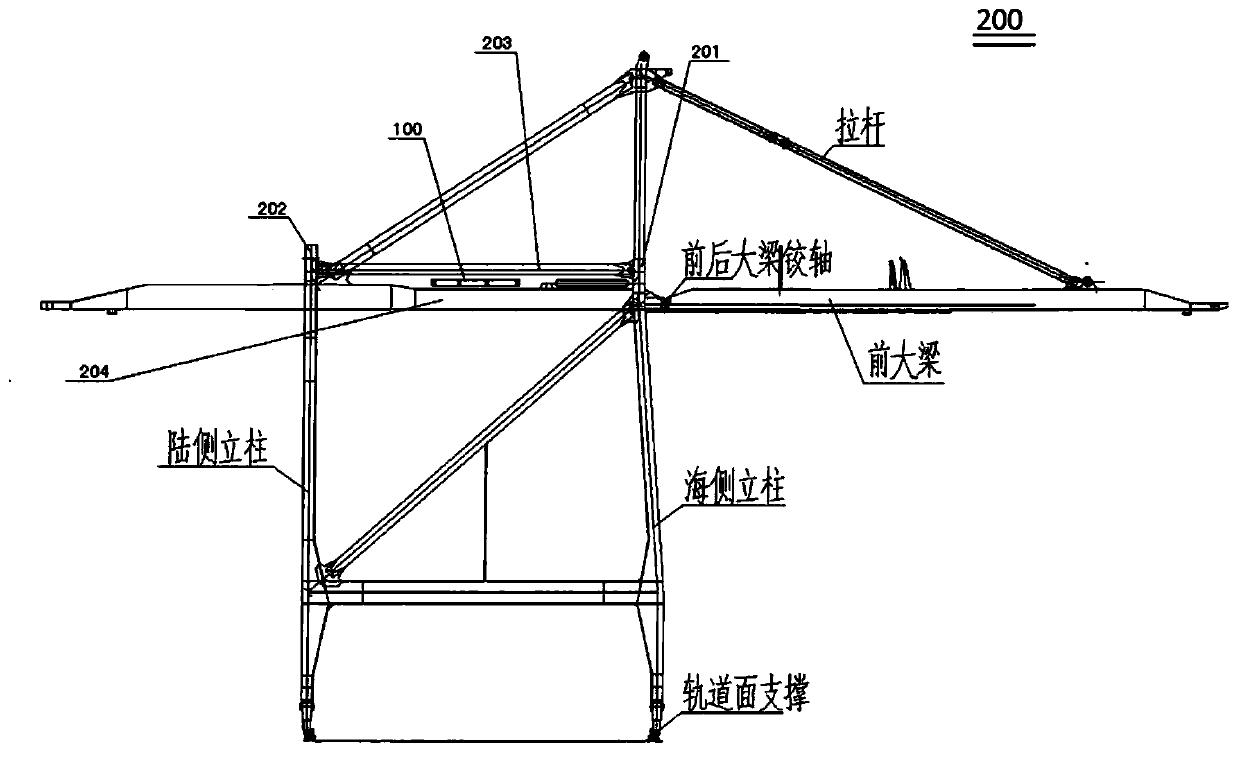

Engine room chassis and mounting method thereof

A machine room and chassis technology, applied in the field of machine room chassis and its installation, can solve the problems of not meeting sufficient safety requirements and rigidity requirements, etc., achieve flexible and adjustable size, prevent excessive deformation, and prevent large-scale free vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

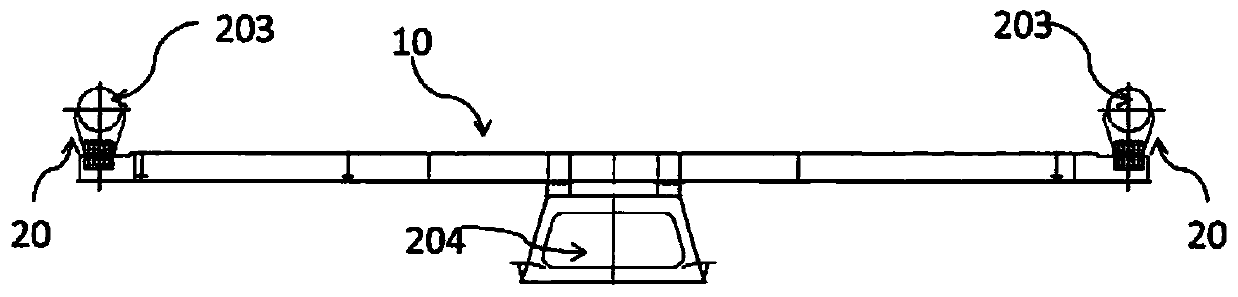

[0054] The first embodiment is mainly applicable to the case where the main support structure 10 is located below the horizontal connecting rod 203 of the quay crane 200 along the direction of gravity, and is suitable for completing installation at low altitudes, avoiding high-altitude operations.

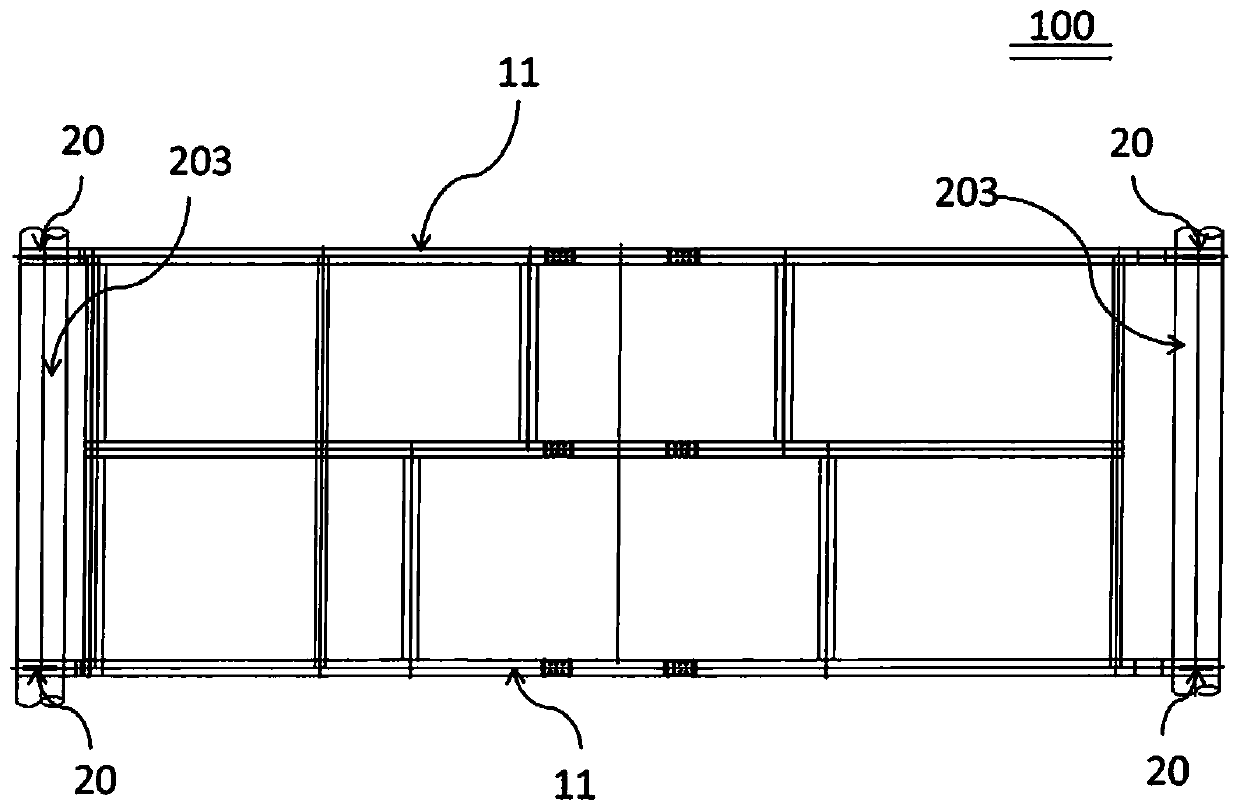

[0055] Such as Figure 3a~3c As shown, the first part 21 is T-shaped steel, the flange plate of the first part 21 is connected with the transverse main beam, and the web of the first part 21 is connected with the third part 23; as Figure 4a , 4b As shown, the second component 22 is a sheet, and the contact end of the second component 22 and the horizontal connecting rod 203 partially surrounds the horizontal connecting rod 203; Figure 5a , 5b As shown, the third part 23 is a double-layer sheet, so as to clamp the first part 21 and the second part 22, that is, the first part 21 and the second part 22 of the auxiliary support 20 after installation are all clamped by the second pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com