Method for detecting compaction degree of powder soil roadbed

A detection method and technology for soil subgrade, applied in the direction of roads, roads, road repair, etc., can solve the problems of the overall damage of the subgrade, the time-consuming and laborious detection process, the inability to display the compaction status in real time, etc., achieving good comprehensiveness and high difficulty in counterfeiting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

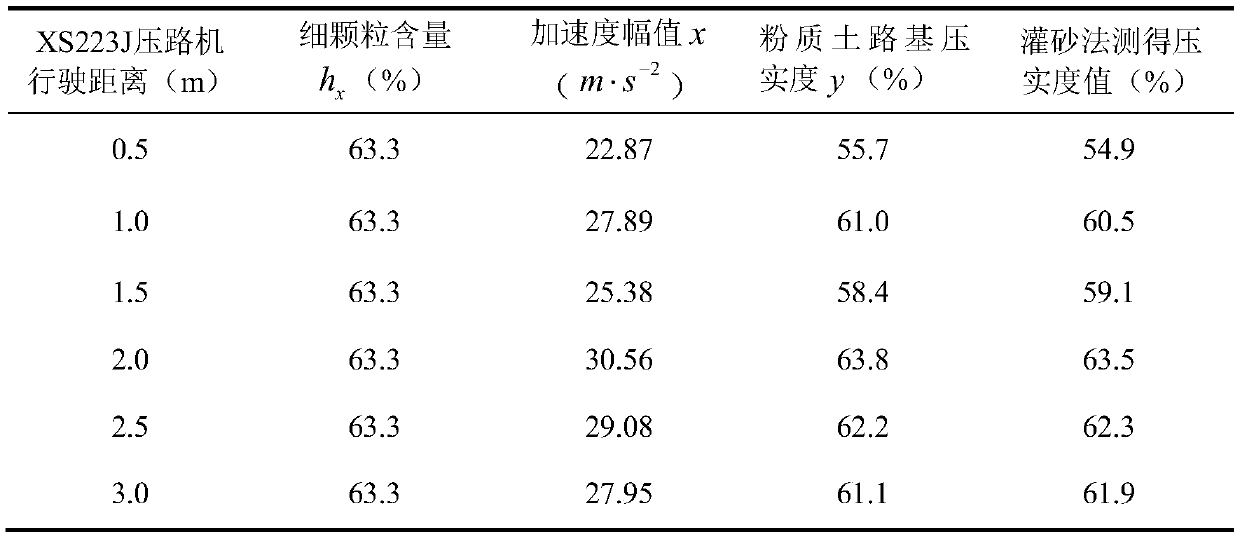

[0024] In this example, a section of 3 meters long non-rolled silty soil subgrade is rolled for the first time, and the scheme of the present invention is used to detect during the rolling process. The process is as follows:

[0025] The silty soil subgrade is sampled, and the composition of the sample is detected (the sieving experiment is carried out according to "Highway Soil Test Regulations" JTG E40-2007; note: the means for detecting the content of fine particles in the subgrade soil is an existing technology, and during specific implementation, As long as the accuracy of the detection results can be ensured, those skilled in the art can select suitable detection means according to actual conditions), and obtain a content of 63.3% of fine particles with a particle diameter less than 0.075mm, i.e. h x = 63.3%;

[0026] The vibratory roller adopts Xugong XS223J type vibratory roller, the acceleration sensor adopts the 1A113E piezoelectric acceleration sensor, the sampling ...

Embodiment 2

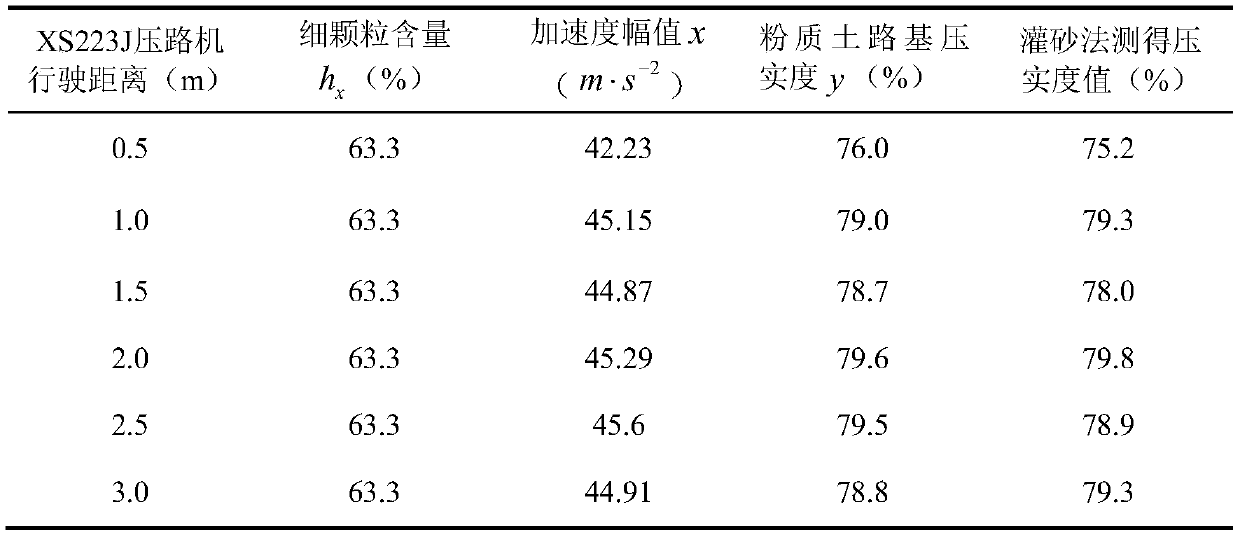

[0030] Carry out the second round of rolling on the basis of Example 1. The action of the vibratory roller and the sampling conditions of the acceleration sensor are the same as in Example 1. After the rolling is completed, the compaction degree is detected at different positions in the rolling area by using the sand filling method. ; After processing the data, there is the following table:

[0031]

[0032] As can be seen from the above table, the test result of the present invention is very close to the test result of the sand filling method. In conjunction with the test result of Example 1, it is shown that the deviation between the test result of the present invention and the test result of the sand filling method is small, and the accuracy of the present invention Better and more practical.

example 3

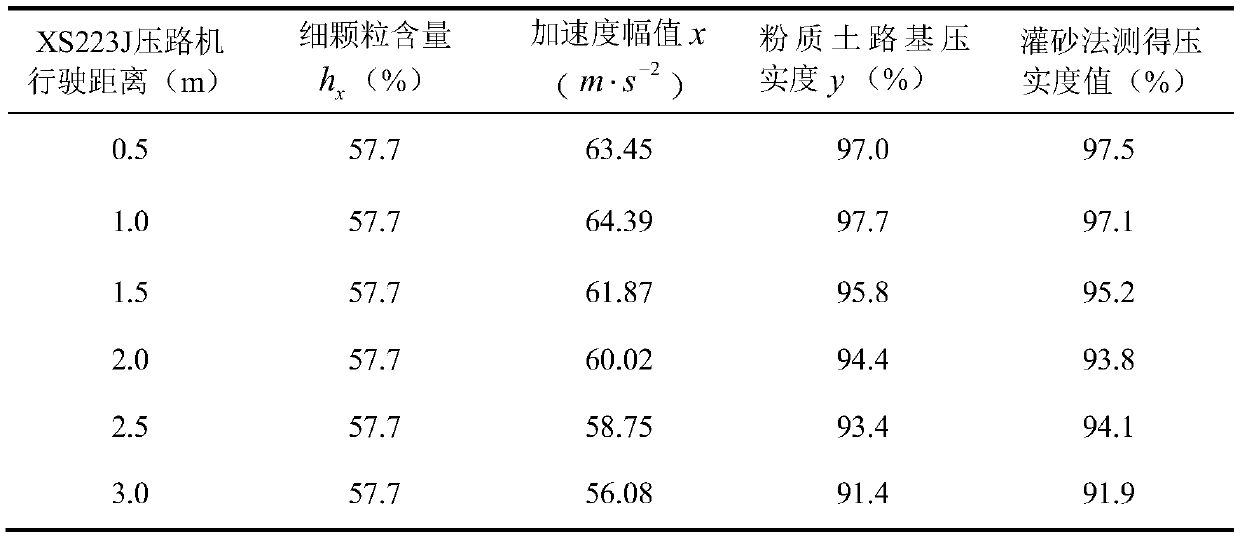

[0034] Different from examples 1 and 2, in this example, a 3-meter-long area is selected for detection on a silty soil subgrade that has been rolled, and the design compaction degree of the silty soil subgrade is ≥95%;

[0035] During detection, the action of the vibratory roller and the sampling conditions of the acceleration sensor are the same as in Example 1. After the rolling is completed, the compaction degree is detected at different positions in the rolling area by the sand filling method; after the data is processed, the following table :

[0036]

[0037] It can be seen from the above table that the subgrade compaction in the range of 1.5-2.0 meters, 2.0-2.5 meters, and 2.5-3.0 meters is unqualified, which is consistent with the detection conclusion of the sand filling method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com