A method for forming radar absorbing material shielding screen

A technology of radar absorbing material and forming method, which is applied in the direction of radio wave measuring system, instrument, etc., can solve the problems of large size, difficult handling, uneconomical cost, etc., and achieves flexible width and height dimensions, simple and practical forming method, and easy to use Cost-effective maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

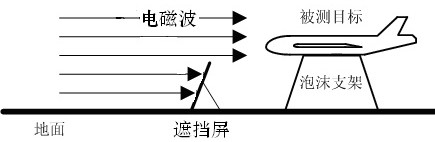

[0032] The present invention is a method for forming a radar wave absorbing material shielding screen, and the steps are:

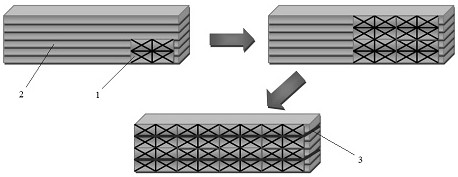

[0033] S1. Use long block-shaped flat plate absorbing materials as back-to-back materials;

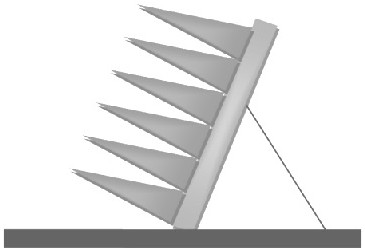

[0034] S2. Install a pyramid absorbing material of the required length in the direction of the incoming electromagnetic wave, and adjust the direction of the pyramid of the material;

[0035] S3. Use non-metallic strings to bundle the pyramid wave absorbing material and the backrest material into one;

[0036] S4. Expand the width and height on both sides and above to form the required radar absorbing material shielding screen.

[0037] After the test, untie the non-metallic string, separate the pyramid wave absorbing material and the backing material, pack it, and transport it back to the room for storage.

[0038] The non-metallic thin rope is a nylon rope.

Embodiment 2

[0040] Shielding screen forming method: use long flat plate absorbing materials as the backrest, and install a single pyramid absorbing material with required length (such as 500mm×500mm or 400mm×00mm, etc., according to specific needs) in front. , adjust the direction of the material pyramid, and use non-metallic strings to bundle the material and the backrest into one through the cone bottom gap of the pyramid absorbing material to form the required radar absorbing material to block the screen-based unit.

[0041] "Flexible" width and height adjustment: according to the actual task needs, add the pyramid wave absorbing material from both sides, "flexible" adjust the width of the wave absorbing material shielding screen (the width of the backrest is also increased according to the actual needs), and then increase the angle from the upper height direction. Cone and backrest, "flexibly" adjust the height and size of the shielding screen of the absorbing material to meet the tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com